Control Systems

Displaying 51 - 60 of 773

Climate control maintenance is the key to efficiency

£480,000 is a lot of money. But that is what I was told it costs one of the UK’s largest automotive manufacturers per hour when they experience downtime on their paint plant. Your overheads may not be as substantial as the above example, but that doesn’t take away from the fact that the old adage you hear in every corner of business and production is true.

By Karl Lycett, Rittal’s Product Manager for Climate Control

23rd July 2019

Motion control looks like it's here to stay

Industrial control is a highly developed field that advances year on year as the underlying technology advances. But will it and all its specialist sub-sets continue to thrive? Gerard Bush, a motion specialist with INMOCO, here gives us his opinion on the matter. All technologies develop over time, with most eventually reaching an upper limit where they are as advanced as they can be. This is clearly evident in older technologies where the peak has been reached.

19th July 2019

Pharmaceutical supplier opts for innovative hygienic flowmeter

Specialist process machinery manufacturer, L.B. Bohle, has developed a cleaning system for the pharmaceutical industry using Bürkert’s innovative FLOWave flowmeter for a compact, hygienic and very accurate process. Incorporating the latest in flow measurement technology has minimised equipment footprint and reduced operating costs as well as maintenance time.

29th May 2019

NI Week: Wireless devices end manual data collection.

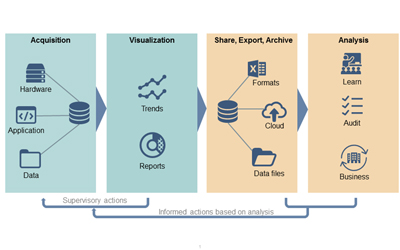

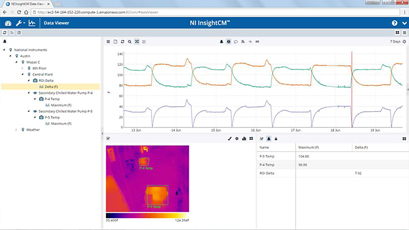

Wireless monitoring hardware has been announced for NI’s InsightCM, a solution for online condition monitoring with full access to data and customisation with the InsightCM Software Development Kit. The new wireless devices automate the otherwise manual process of route-based data collection.

23rd May 2019

Controller expansion modules bring adjustable interfaces

It has been announced that PLC Next Technology now offers users even more flexibility for individual requirements with PLC Next Controllers from Phoenix Contact. The interfaces of the PLC Next Controllers can be adjusted using expansion modules. These expansion modules are then connected to the left side of the controller.

22nd May 2019

Sustainable heating systems for the wood industry

At Ligna 2019, digital solutions and service concepts for efficient plant operation will be presented by Viessmann, for industry, commerce and local authorities at Ligna 2019 from 27th to 31st May in Hannover. Alongside service, the main focus is on new digital solutions for optimum plant operation and cutting-edge engineering. The Industrial Systems Division of the Viessmann Group will be exhibiting in Hall 26, Stand G 27.

20th May 2019

AI module to improve industrial production

Industrial workers can now more easily use the data from their equipment to predict production issues and improve processes with their existing automation and control skill set. The new FactoryTalk Analytics LogixAI module, formerly known as Project Sherlock, uses artificial intelligence (AI) to detect production anomalies and alert workers so they can investigate or intervene, as necessary.

1st May 2019

Operations software enables seamless system integration

FAST/TOOLS R10.04, the latest version of Yokogawa Electric’s real-time operations management and visualisation software. It is released for sale on April 18 as part of the OpreX Control and Safety System family. A highly flexible and scalable supervisory control and data acquisition (SCADA) solution FAST/TOOLS R10.04 is suitable for use in everything from smart IoT-enabled applications to enterprise-wide integrated operations spanning multiple sites and subsystems.

17th April 2019

.jpg)