SICK (UK) LTD

Address:

Waldkirch House, 39 Hedley Road, St Albans, Hertfordshire

AL1 5BN

United Kingdom

AL1 5BN

United Kingdom

SICK (UK) LTD articles

Displaying 1 - 20 of 65

SICK’s deep learning brings simplicity to AI inspection

SICK has launched a suite of Deep Learning apps and services to simplify machine vision quality inspection for challenging components, assemblies, surfaces or food produce, especially those that have previously defied automation and remained distinguishable only by human inspection.

13th October 2020

Capacitive level sensor provides a non-contact solution

Compact, economic and quick to install, SICK’s CQF16 capacitive level sensor has been developed to provide a universal, non-contact solution wherever the fill level of water-based liquids must be detected in non-metallic vessels, tanks or pipes. The robust, ECOLAB-certified SICK CQF16 level sensor is supplied with a one-clip mounting bracket that can be fastened securely to the wall of any pipe or container. Using the capacitive measurement principle, it accurately detects water-based media regardless of foam, moisture or deposit build-up on the inside of the vessel.

25th September 2020

Conquering new frontiers with world’s smallest safety laser scanner

SICK has launched the world’s smallest safety laser scanner, the nanoScan3, designed for easy and economical integration into the smallest of machine designs, particularly for automated guided vehicles, carts, mobile platforms and service robots. The ultra-compact SICK nanoScan3 is just eight centimetres tall, so it can fit snugly into the spaces in machines where safety laser scanners could not previously have been located.

8th January 2020

Sensor integration machines boost SICK’s ‘Edge’ processing power

SICK has extended its Sensor Integration Machine (SIM) family with the launch of two high-performance, one-box, processing hubs that fuse decentralised, multi-sensor co-operation with field-to-cloud connectivity as part of Industry 4.0. SICK SIM1000 and SIM2000 Sensor Integration Machines are programmable sensor connection and data processing hubs that open up new possibilities to develop custom applications in SICK’s AppSpace ecosystem.

19th December 2019

SICK goes flat out for sub-miniature performance

WITH the launch of its G2 Flat family of photoelectric sensors, SICK has shrunk outstanding performance into a miniature format. The ultra-thin sensors are designed to integrate snugly into small machinery and conveyors, or for tight fits in robotic arms and grippers. Starting at just 3.5mm thick, the SICK G2 Flat family of proximity and through-beam sensors achieve highly-reliable detection of objects of almost any size, thanks to the unrivalled precision of SICK’s PinPoint visible laser light spot technology, even for jet-black, transparent, mirrored or shiny surfaces.

19th December 2019

Rough and tough sensors thrive in harsh environments

WITH the release of Inox versions of its GR6 rectangular and GR18 cylindrical sensors, SICK has delivered rough, tough, high-availability photoelectric performers for detection duties in harsh environments such as chemical washdown or the presence of aggressive oils, lubricants and dust.

24th October 2019

SICK’s ‘Tiny TiMs’ first to plug the low-risk safety gap

SICK has launched the first 2D LiDAR sensors safety-certified to PL b, specifically designed to plug a gap for lower-risk applications where safety-rated integration is needed in small, low-speed Automated Guided Vehicles and Carts, service robots or collaborative robots. The SICK TiM361S and TiM781S 2D LiDAR sensors are economical, lightweight and compact with a safety certification to EN ISO 13849-1:2015 PL b and can be integrated inconspicuously into low-speed, small or lightweight mobile or stationary applications, following completion of an appropriate risk assessment.

22nd August 2019

SICK shrinks UHF RFID read/writing with smallest industrial device

SICK has launched the smallest industrial UHF RFID read/write device of its kind, the RFU610, creating new opportunities to integrate RFID track and trace capability in automated machines and mobile vehicles across production, materials handling, and logistics environments. Almost half the size of SICK’s next-level, mid-range RFU620 reader, the RFU610 needs an installation space of just 80x92x38mm and achieves an impressive scanning range of ≤0.5m.

15th August 2019

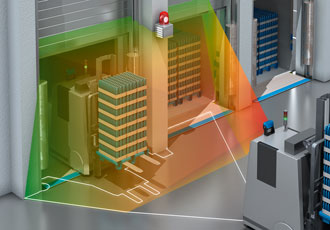

World’s first safety laser scanner certified to IEC TS 62998

SICK UK has announced the launch of the outdoorScan3, the first laser scanner in the world to be safety-certified for use outdoors. The outdoorScan3 Safety Laser Scanner safely and reliably monitors hazardous areas around machines and industrial vehicles outdoors with a high level of availability.

8th August 2019

Opening the doors of the Industry 4.0 smart factory at PPMA

Industry 4.0 is a hot topic for everyone in the industry at the moment, and it is no different for SICK. The sensors company are inviting PPMA Total Show visitors to gain an exclusive behind-the-scenes insight into its pioneering new Industry 4.0 smart sensor production facility in Freiburg, Southern Germany.

6th August 2019

2D quality inspection smart SensorApp launched

SICK has launched Presence Inspection, a freely-downloadable, easy to set-up SensorApp for its Inspector P family of programmable 2D vision cameras. The addition extends the performance and versatility of SICK’s 2D offering for presence/absence quality inspection, validation and process control tasks.

25th July 2019

Re-inventing lightgrid as a versatile light chain

It has been announced that SICK has reinvented the lightgrid as a versatile ‘light chain’ of cascading photoelectric sensors. The FlexChain detection system is a completely new way of configuring light grids that offers unprecedented freedom for automated plant and machinery applications.

10th May 2019

SICK opens up Industry 4.0 with its first IO-Link encoder

With the launch of the SICK AHS36 (singleturn) and AHM36 (multiturn) IO-Link absolute encoders, SICK has opened up wide-ranging new possibilities to integrate rotary motion sensing into the ‘smart’ sensor configurations of automated machinery. The SICK AHS36 and AHM36 36mm IO-Link encoders are SICK’s first range of absolute encoders with IO-Link.

13th March 2019

NAV-LOC localisation sets AGVs free from reflectors

SICK has set Automated Guided Vehicles free from the need for reflectors or other physical markers with the all-in-one NAV-LOC localisation solution, enabling them to navigate more reliably and efficiently around shop floor and warehouse environments. The SICK NAV-LOC (Localisation On Contour) is an easy-to-set up solution based on a SICK NAV 360o LiDAR scanner that can be integrated into new or existing AGVs.

1st March 2019

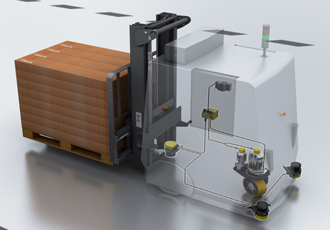

Safe EFI-pro system for network integration

With the launch of its Safe EFI-pro System, SICK has delivered standard industrial Ethernet-based safety network integration for highly-adaptive and dynamic safeguarding in automated production and logistics environments to SIL 3/PLe. The SICK Safe EFI-pro System is a single-source solution that provides the foundation for simpler, more productive and responsive machinery safety, particularly valuable for dynamic applications like autonomous vehicles and human/robot collaboration.

22nd January 2019

Sensor powers high speed image processing in compact device

SICK has pushed forward the boundaries of 3D vision inspection in a wide range of industrial applications with the launch of the SICK Ranger3 camera, thanks to a breakthrough CMOS sensor that powers unprecedented high speed image processing in a compact device. SICK’s Ranger3 high definition streaming camera is the first to be powered by SICK’s innovative Imager with ROCC (Rapid On-Chip Calculation technology).

19th December 2018

Absolute encoders with HIPERFACE boost direct drive feedback

With the introduction of its SES and SEM absolute encoders, SICK has delivered a motor feedback system with the standard HIPERFACE interface that improves precision and reliability for hollow shaft motors and direct drives. The compact SICK SES70/90 singleturn and SEM70/90 multiturn encoders can be mounted directly on a hollow drive shaft without the need for additional mounting tools.

28th November 2018

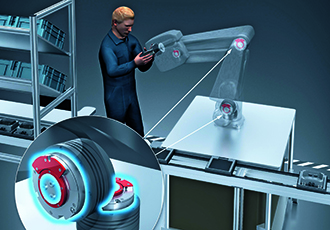

Safety relays provide 'New Tricks' from an old friend

When it comes down to choosing the right safety relay, it is important in identifying the smallest performance improvements as it can result in big productivity gains. That’s why SICK has developed its ReLy safety relays to achieve a 10ms response time with a class-leading, long and durable product lifecycle.

14th May 2018

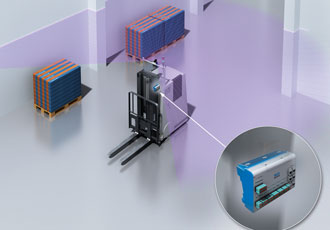

Plug-and-play ‘Snapshot’ sensor launched for 3D detection

A configurable plug-and-play 3D detection sensor has been launched by SICK based on its Visionary-T range of industrial 3D imaging cameras, harnessing the imaging power of SICK’s single-snapshot Time-of–Flight (TOF) technology for a range of detection and collision warning duties. With on-board processing, the Visionary-T DT sensor can be easily configured for a variety of applications to detect the presence or absence of 3D objects. It therefore offers a versatile, entry-level option for collision warning on forklifts, Automated Guided Vehicles (AGVs) and Carts (AGCs).

1st May 2018