RTP Company

Address:

580 E. Front Street

Winona, MN

55987

United States of America

Winona, MN

55987

United States of America

RTP Company articles

Displaying 1 - 20 of 21

RTP introduces new plastic technologies at Fakuma show

RTP Company will feature successful applications created from its portfolio of industry-leading engineered thermoplastic compounds at the upcoming Fakuma exhibition in Friedrichshafen, Germany. Representatives from RTP Company’s facilities in Ladenburg, Germany and Beaune, France will be available at Fakuma Booth #A4-4221. Highlighted will be a new proprietary alloy technology known as RTP 2000 HC, a series of specially formulated compounds designed to maintain strength, functionality, and integrity, even with repeated exposure to hospital cleaners used to disinfect medical devices.

29th September 2015

New structural thermoplastic from RTP fills performance gap

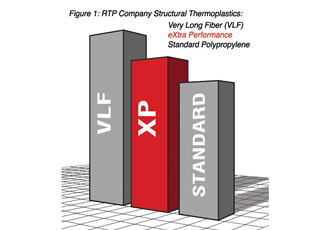

RTP Company is pleased to announce the development of new RTP 100 eXtra Performance (XP) Compounds, a series of thermoplastic compounds formulated for higher strength, modulus and impact properties than any standard chopped fiberglass polypropylene (PP) compounds available on the market today. With strength, stiffness, and impact resistance performance that is close to RTP’s Very Long Fiber (VLF) compounds, combined with the lighter weight and chemical resistance of standard PP compounds, RTP 100 XP Compounds (see attached figure 1) provide a new realm of design possibilities for applications in the automotive, furniture, appliance, storage, industrial/construction, electronics, and energy markets.

17th September 2015

RTP develops plastic technology that resists chemical attack from hospital disinfectants

RTP Company has developed a proprietary alloy technology designed to maintain strength, functionality, and integrity, even with repeated exposure to hospital cleaners used to disinfect medical devices. Known as the RTP 2000 HC series, these thermoplastic compounds can help solve cracking issues in existing devices and open a new realm of possibilities for the design of hospital equipment and plastic housings that require frequent disinfection, such as mobile ultrasound and x-ray machines, enteral feeding devices, drug infusion pumps, blood filtration equipment, and more.

16th June 2015

Engineered Sheet Products Develops Clear, Anti-Static Sheet For Electronics, Dust, And Static-Free Applications

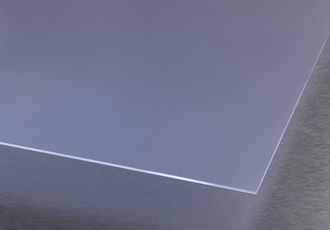

Engineered Sheet Products has developed a unique thermoplastic sheet with anti-static properties inherent throughout, providing permanent protection from the damaging effects of static electricity and dust. Known as PermaStat sheet, this compounded thermoplastic sheet features consistent surface resistivity of 109 to 1011 ohms/square, offering an excellent solution for OEMs and processors who require superior ESD protection and dust control. When higher conductivity and lower surface resistance (107 to 108 ohms/square) are required, ESP also offers PermaStat Plus sheet.

21st May 2015

RTP Company Offers Thermoplastic Compounds Solutions To Global Shortage Of PEI Polymer

RTP Company is helping to address the global shortage of Polyetherimide (“PEI”) by offering a number of thermoplastic compounds that serve as viable alternatives. These compounds include amorphous materials based on sulfone or semicrystalline materials that have been modified, alloyed, and/or reinforced to achieve very similar physical properties to PEI. Engineers from RTP Company can customize and fine-tune these compounds to meet specific application requirements including offering compounds in custom colors. RTP Company is hosting a webinar entitled “Alternatives to PEI and PEI Compounds” on Thursday, December 11, 2014 at 10:00am CST to discuss these options; a recorded version will be available after the live session.

9th December 2014

RTP Company Introduces New Conductive Extrusion Compounds Designed To Improve Consistency In Conductivity And Mechanical Properties

RTP Company has expanded its line of conductive compounds to include those specifically designed for extrusion processes and applications. Produced on dedicated manufacturing equipment designed for the highest level of uniform carbon black dispersion, RTP Company’s Conductive Extrusion Compounds provide consistent electrical conductivity, electrostatic discharge (ESD) protection, and maximized physical properties.

18th September 2014

Production of VLF compounds supports regional demand

A state-of-the-art pultrusion line is now producing Very Long Fiber (“VLF”) compounds at RTP Company's facility in Monterrey, Mexico. This VLF manufacturing location in North America will support regional demand while providing a consistent supply near the company’s global customers operating in Mexico, Brazil, and other South and Central American countries.

15th August 2014

RTP Company's Conductive Compound Meets Stringent Safety Requirements for Mining Pump

When All-Flo was challenged to construct an entire pump with conductive, but non-metallic materials, it worked in partnership with custom compounder RTP Company who recommended a material that enabled the successful production of a specialized version of the company's 1 inch (25 mm) polypropylene AOD pump.

2nd November 2012

RTP Company's Very Long Fibre Composite Delivers Increased Durability and Reduced Weight for Robotics Gearbox

When AndyMark recently reviewed its catalogue for components that could be improved, an aluminium gearbox kit captured its attention. Co-founder Andy Baker, a trained mechanical engineer, believed the housing could be made with a reinforced plastic, which would mean fewer parts for easier assembly, reduced weight, and increased durability.

6th August 2012

RTP COMPANY'S GLASS FIBER-REINFORCED PLA BIOPLASTIC COMPOUNDS IMPROVE STRENGTH AND THERMAL PERFORMANCE

-- Global custom engineered thermoplastics compounder RTP Company has commercialized the industry's first line of glass fiber-reinforced polylactic acid (PLA) compounds that overcome many limitations of unmodified PLA by delivering greater strength, stiffness, and thermal performance. These new materials, which target durable and semi-durable applications, are the latest extension of RTP Company's family of engineered bioplastic compounds that use resins derived from rapidly renewable resources.

13th June 2011

RTP Company's Very Long Fiber Composite Improves Performance of Small-Scale Wind Turbine Blades

When China-based Hunan ZKenergy Wind Power Industrial Technology wanted to offer a reliable source for providing electricity to remote areas around the world, it adapted the technology of wind turbines to produce affordable, small-scale units suitable for off-grid locations. A crucial element in their success is very long glass fiber reinforced thermoplastic composite from custom compounder RTP Company that is used to injection mold the blades. The compound was chosen over other reinforced plastics due to the enhanced mechanical properties very long fiber composites provide.

25th June 2010

RTP Company Introduces Biocompatible Thermoplastic Elastomers For Medical Devices

RTP Company has introduced a series of biocompatible styrenic-based thermoplastic elastomer (TPE) compounds suitable for use in medical devices. RTP 2700 S MD Series materials have been pretested for compliance with ISO 10993-5/10/11 biocompatibility standards and are available in hardnesses ranging from 30 to 80 Shore A.

10th June 2010

RTP COMPANY'S COLOR MASTERBATCHES PROVIDE NATURAL COLOR FOR COMPOSITE MASONRY PAVERS MADE OF RECYCLED RUBBER AND PLASTICS

When VAST Enterprises wanted to offer the construction industry a green alternative to conventional paving systems, it developed a composite masonry paver system made entirely of recycled tires and plastic bottles. In order to overcome the extreme 'blackness' of the tires, however, an effective coloring method was needed to provide the pavers with the rich, natural earth tones of competitive materials. VAST consulted with engineers at custom compounder RTP Company who formulated a polymeric-based color masterbatch for the pavers.

24th May 2010

RTP Company High Gravity Compound Improves Performance of Golf Discs

Gateway Disc Sports, supplier of high performance golf discs and accessories, has partnered with global custom thermoplastic compounder RTP Company to upgrade their Shur-Grip product line of discs. Gateway's aim was to improve grip performance while still maintaining flexibility, making the discs more thrower-friendly for both novice and professional golfers.

Our main goal was to find a material that would accept mineral additives to reach a density of 2.0, explained David McCormack, owner of Gateway.

11th December 2009

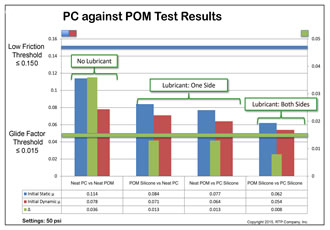

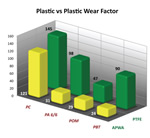

RTP Company Introduces All-Polymeric Wear Additive Compounds with Improved Properties

Global custom engineered thermoplastic compounder RTP Company recently commercialized a new line of all-polymeric wear additive (APWA) compounds offering improved wear resistance. Free of particulate or fluid additives, the materials provide excellent plastic-on-plastic performance without sacrificing properties inherent to the host resin.

18th May 2009

RTP Company Expands Its Color Compounding Capacity To Ensure 5-Day Lead Time

The Color Division of specialty compounder RTP Company announced that it has expanded its capacity on a number of fronts for the production of masterbatches and precolored resins. Additional capacity allows us to meet customer needs more effectively and increases our delivery flexibility, said Jean Sirois, General Manager - RTP Color. Currently, we offer a 5-day lead time for color masterbatches and precolored resins. As sales increase, the only way to continue supplying in 5-day window is to have a capacity growing at a faster rate so that we can stay ahead of the curve.

12th June 2008

RTP Company Introduces Next Generation of Bondable TPEs Formulated to Provide Cost-Effective and Functional Performance

The TPE Division of specialty compounder RTP Company has introduced a new series of bondable thermoplastic elastomer compounds -- RTP 6042 Series. Standard grades in the series have been formulated to bond to a variety of rigid substrates including PC, ABS, PC/ABS, PC/PBT, PC/PMMA and RTPU resins. The new RTP 6042 Series products offer a wider processing window than the RTP 6002 Series, which they replace. Additional benefits include superior bonding performance and more consistent mechanical properties across a hardness spectrum from 50 to 75 Shore A.

2nd May 2008