Oilgear

Address:

37 Burley Road,

Leeds

England

LS3 1JT

United Kingdom

Leeds

England

LS3 1JT

United Kingdom

Phone: +44-113-3947300

Web: http://oilgear.com/

Oilgear articles

Displaying 1 - 9 of 9

Proper servicing will make hydraulics run and run

The operational demands of hydraulic equipment has increased significantly over the last 30 years, increasing the importance of planned maintenance and servicing in order to maximise working life and minimise operating costs. David Atkinson, Service Centre Manager at Leeds-based Oilgear, runs through the basics of looking after a hydraulic system.

8th June 2017

Sports stadia reach new levels of automation thanks to hydraulics

As the world modernises so do sports stadia, recently they have become more and more sophisticated. First there were closable roofs, then movable seating; now even the pitches can be reconfigured to suit different sports or other activities. Requiring massive loads to be moved with speed, precision and safety, stadium architects naturally turn to hydraulic specialists such as Oilgear.

31st March 2017

Getting a fresh take on subsea hydraulic control

An approach for controlling subsea wellhead Blow-Out Preventers (BOPs) and production systems was established during the 1970s. This approach involved using hydraulic fluid power as a means for shifting valves, rams, and actuators that are located as far as two miles below a platform or vessel.

13th February 2017

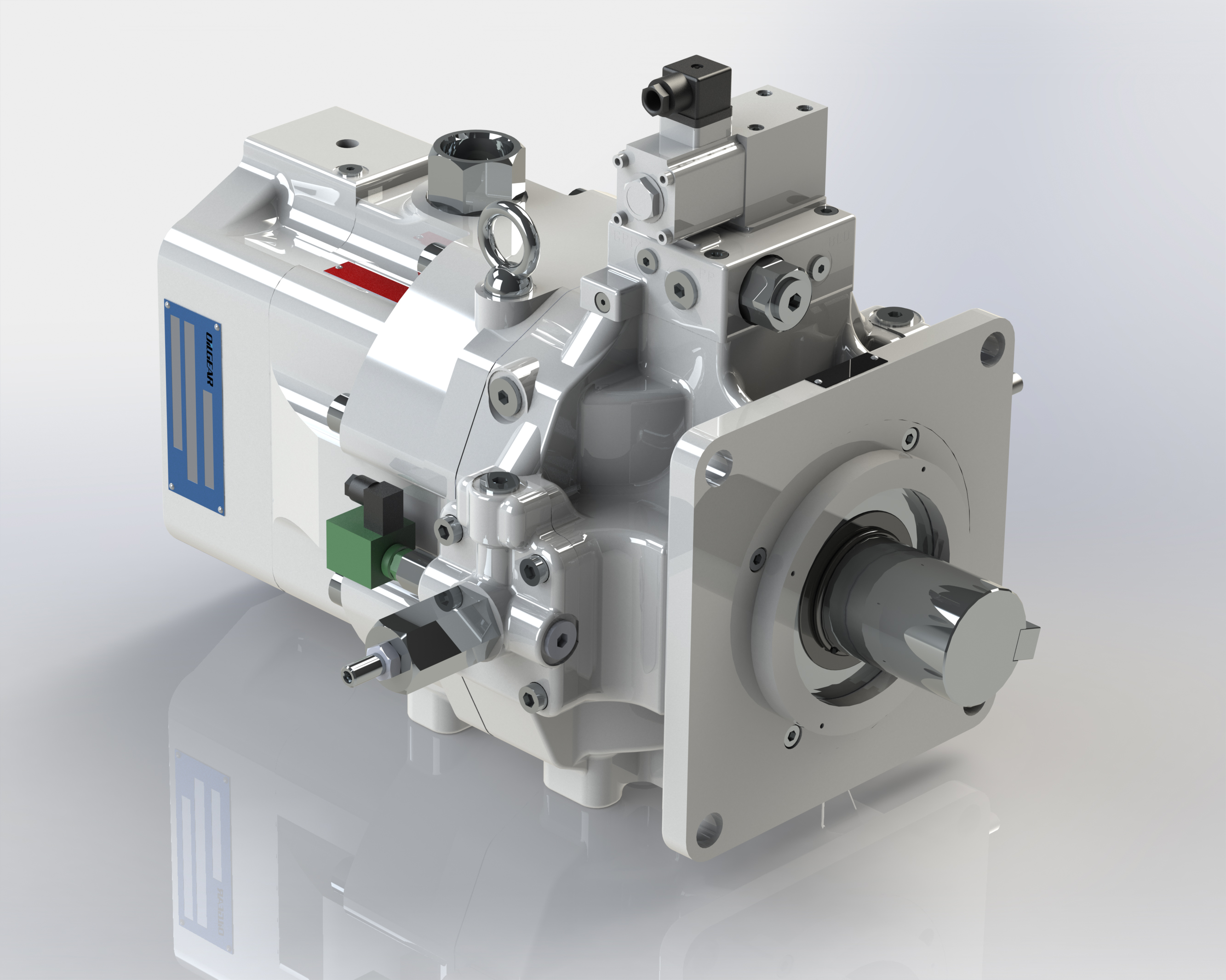

Innovation and performance for hydraulic systems

Hydraulic systems should have an operating life of decades, permitting that they are correctly designed, installed and maintained. Even in the harshest environments, such as steel production and offshore, you’ll probably find pumps and manifolds which were first installed before half your workforce were born. With such pressures placed on these systems it’s vital that they are manufactured to the highest of standards and tested for suitability.

19th January 2017

Hydraulics company driven to new heights by computer-aided engineering

Far more than just an assemblage of components, a modern car has the ability to achieve the levels of speed, comfort, handling, economy and safety that is required to function well and each component will have had its design refined multiple times. The way they eventually work together as systems and sub-systems is indicative of layer upon layer of careful optimisation.

20th December 2016

Helping to improve offshore efficiency

In order to deliver more cost effective solutions for the oil and gas industry, Oilgear has invested significantly in its manufacturing automation and testing facilities. Very few industries are as demanding or as hazardous as the offshore sector and the closely connected subsea industry. And, creating engineering solutions for these industries requires an almost forensic attention to detail and a build quality that exceeds most aerospace applications.

4th November 2016

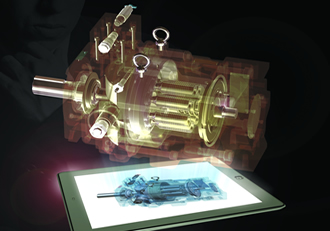

Tomorrow’s hydraulic problems solved through innovation

Now renowned for rapid leaps in technology, industrial hydraulic engineering is rather a gradual progression that overcomes problems and incorporates evolving technologies as they arise. However, every challenge needs a champion and at the forefront of the product development process is a company that excels in delivering innovation.

2nd November 2016

Oilgear digs deep to support South African miners

The newly developed range of variable speed pumps at Electra Mining Africa 2016 will be shown by hydraulic company Oilgear. It will take place in the Expo Centre Nasrec, Johannesburg from the 12th to the 16th September. Electra Mining is South Africa’s biggest mining, industrial, electrical and power generation exhibition.

24th August 2016

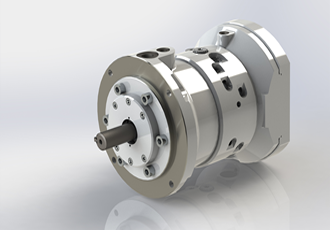

Pump developed to be suitable for all industrial occasions

One of the most common hydraulic pumps is the axial piston, which is used in many industrial applications as well as off-highway and mining. Throughout the industrial workplace, hydraulic pumps provide a great deal of motive power, efficiently translating the rotary motion of a prime mover into hydraulic oil flow that can be easily routed and used for a vast range of tasks.

14th July 2016