NVision, Inc

Address:

440 Wrangler Drive

Suite 200

Coppell

TX 75019

United States of America

Suite 200

Coppell

TX 75019

United States of America

NVision, Inc articles

Displaying 1 - 14 of 14

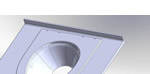

NVision's Consulting and Engineering Services Improve Fracking Parts

A major manufacturer of hydraulic fracturing components for the oil and gas industry utilized NVision's full spectrum of engineering services, from consulting to 3D scanning, CAD modeling and 3D non-contact inspection, to improve the design of crucial parts and speed their certification. NVision was able to compare multiple versions of the same parts and determine geometric variation between the versions that passed tests and those that failed. That information was then used by NVision engineers to develop new 3D CAD models with critical dimensions and tolerances, leading to improved designs and faster certification of the parts.

4th November 2014

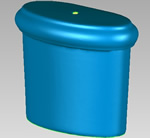

Robots Blaze New Path for Glaze

NVision recently helped a major original equipment manufacturer of bathroom fixtures produce the path for a robot to follow while spraying enamel on the exterior and bowl surfaces of a new product the company is introducing toilet bowls and tanks are made from vitreous china, which is a special mix of several different kinds of clay.

16th April 2013

NVision Launches New Project Portal for Clients

NVision, Inc. announced that it has launched a new project portal for its clients. The new portal, which utilizes TeamPlatform, provides NVision’s clients with full, speedy access to customized data exchange Web pages related to their projects.

24th April 2012

NVision Helps Reverse Engineer Optical Retailer's Store Display, Enabling Millions in Annual Sales

A national marketing services provider recently used NVision Inc.'s Engineering Service Division to reverse engineer an essential part in a store display for one of the nation's largest optical retailers. NVision was able to quickly scan the part and provide the CAD files necessary to mass-produce it for the display in the retailer's stores nationwide, enabling millions in annual sales.

12th December 2011

NVision Saves Toilet Manufacturer $20,000 and Four Weeks in Developing New Model

Aircraft Technologies saved $20,000 and four weeks in reduced tooling costs/time for a new model by utilizing NVision’s laser scanning and engineering services. “By scanning an existing upper and lower bowl assembly and modifying the resulting CAD models to fit parts that we already had tooling for, we substantially reduced the tooling cost and got the product to market faster,” said Mark Riebesehl, Owner and Vice President of Operations for Aircraft Technologies.

1st November 2011

NVision Helps Orthodontic Company Recalibrate CT Scanner

NVision, Inc. recently provided an orthodontic company with the information it needed to recalibrate its CT scanner. The company, an orthodontic supplier, utilized NVision's Engineering Service Division to scan a human skull as part of the verification/inspection process for its in-house CT machine. The scanning results provided by NVision contained all the measurement data necessary for the orthodontic company to recalibrate its CT machine to the highest possible level of accuracy.

21st September 2011

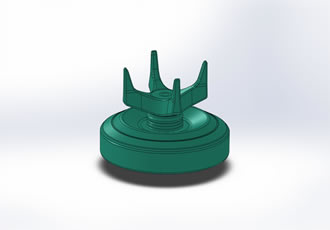

NVision Scanner Helps Reverse Engineer Key Impellor at Hydroelectric Plant

Engineers from NVision, Inc., using the company’s HandHeld Scanner, were able to quickly reverse engineer a large impellor for a major hydroelectric facility, sparing the facility what would have been an extended shutdown had they needed to produce a replacement impellor from scratch. In less than one week, NVision scanned the original impellor and provided a computer model of it to the facility, which then used the model to manufacture a duplicate impellor for installation. In the end, only a relatively short shutdown was necessary to accommodate the scanning and reproduction of the impellor.

16th August 2011

NVision Now Offering Product Defect Analysis

NVision, Inc.’s Engineering Service Division is now offering product defect analysis, which can potentially be introduced in product liability litigation to prove a manufacturer innocent of producing a defective or harmful product. The company has partnered with Materials Analysis, a Dallas-based engineering firm specializing in litigation support, to provide this service.

14th June 2011

NVision's HandHeld Scanner Helps Keep USAF Planes Combat-Ready

Engineers and machinists at several United States Air Force (USAF) bases are now using NVision's HandHeld laser scanner to reverse engineer complex aircraft parts, which are then machined to the highest level of accuracy and installed, maintaining USAF planes in peak working condition.

Reverse engineering is often required for aircraft that were originally designed without computer aided design systems (CAD) and for which even blueprints can be very difficult to obtain.

25th January 2011

NVision Helps Soft Air Produce Handgun Replica Three Months Faster

Soft Air USA used NVision's laser scanning services to save three months in getting an Airsoft replica of FN Herstal's FNP9-17 handgun to market. This is a significant time-savings over Soft Air's previous process, which involved making silicon molds of real guns and using the molds to create injection molds that in turn make the replica Airsoft guns. Laser scanning saves time because it eliminates the need for manual touchup of the silicon mold and the resulting CAD model of the real gun can then be electronically sent to manufacturers in Asia.

23rd November 2010

NVision HandHeld Scanner Helps Increase Life of Hydraulic Fracturing Tools

A major manufacturer of hydraulic fracturing tools for the oil and gas industry is using NVision's HandHeld laser scanner to increase the performance and life of its products by gaining a clearer picture of erosion patterns. The company previously used ultrasonic sensors to measure discrete points in a gridded pattern after erosion testing with proppant. The HandHeld Scanner provides a much clearer understanding of erosion patterns by measuring millions of points and providing a comparison of the geometry before and after testing with color deviation models showing the amount of material that has been eroded in each area of the tool. This information helps engineers gain an intuitive understanding of tool performance, which in turn helps improve design and substantially increase tool life.

7th October 2010

NVision Creates Reverse Engineering Blog

NVision, Inc. has created an online forum for engineers to discuss Reverse Engineering issues and problems and receive answers to their questions. The blog can be viewed at http://reverse-engineering-services-nvision.com/blog/.

21st September 2010

NVision Scanners Provide Crucial Evidence

Materials Analysis, Inc., has used NVision’s non-contact MAXOS measurement system and HandHeld Scanner to provide critical assistance in a number of recent product liability cases. “The high levels of accuracy provided by non-contact scanning can often rule out hypothesized causes of accidents. In one case they even served as a benchmark to prove that a defect was too small to be adequately documented, preventing the evidence from being irreversibly altered by unnecessary sectioning,” said Mark Allen Lewis, Staff Engineer for Materials Analysis. “Another key advantage of scanning is the ability to quickly generate electronic solid models that are much easier for non-technical people to visualize than blueprints.”

22nd June 2010

Delta Air Lines Improves Blade Maintenance with MAXOS

Delta Air Lines uses the MAXOS non-contact measurement system from NVision in its contract maintenance operations to achieve the highest possible accuracy in overhauling turbine blades and vanes. The traditional method of measuring blades and vanes to determine the level of repair required and to inspect subsequent repairs involves a series of manual measurements. “We have substantially improved on the traditional approach by using the MAXOS to provide consistent and repeatable measurements on parts with complex geometries and shiny finishes,” said Cameron Leonard, Special Projects Coordinator for Delta Air Lines.

6th May 2010