NSK UK Ltd

Address:

Northern Road

Newark

Notts

NG24 2JF

United Kingdom

Newark

Notts

NG24 2JF

United Kingdom

Phone: 01636 643031

NSK UK Ltd articles

Displaying 21 - 40 of 160

A new-generation DIN-standard ball screws unveiled at EMO

Using the recent event, EMO Hannover 2017, NSK launched a number of new innovations designed to enhance machine tool performance. Among the major introductions was a new generation of DIN-standard ball screws. The high-speed, low-noise ball screws not only overcome the specific challenges of European machine tool applications, but also conform to DIN 69051 (ISO 3408) with regard to both dimensional and tolerance classes.

13th October 2017

Ready-to-install bearings on display at Agritechnica 2017

At Agritechnica 2017, taking place in Hanover, Germany, from 12th to 18th November, NSK will exhibit a wide range of rolling bearings that have been purpose-designed for use in agricultural machinery. At booth E44 in hall 15, the company’s display will centre on Agri Disc Hubs and Large Hubs. These ready-to-install units contain double-row, angular-contact ball bearings which are used extensively in agricultural machines that have to operate in very harsh conditions.

12th October 2017

Years of innovation provided in high-speed rail bearings

An unwavering goal to maximise safety in high-speed rail travel has led NSK to provide more than half of century of innovations that date back to the very first generation of Shinkansen bullet trains in Japan. Indeed, advanced development programmes have continued apace to the present day. This is because the latest-generation trains are getting even faster, which places yet higher demands on bearing technologies.

4th October 2017

NSK gains SNCF homologation for TGV wheelset bearings

The national railway company of France, SNCF, has granted final homologation for the use of NSK wheelset bearings for TGV very high-speed trains. This confirmation is the culmination of a five-year project that has seen NSK engineers liaise closely with SNCF to ensure that exact requirements could be met. Although NSK already received similar approvals in Japan, China and Korea, it is the first time that the company has received a homologation for an application of this type in Europe.

9th August 2017

New bearing and ball screw innovations from NSK at EMO

The forthcoming EMO 2017 exhibition will see NSK shining the spotlight on a number of new and recent innovations for the global machine tool market. These will include advances in angular contact ball bearings for main spindles, deep groove ball bearings for spindle motors, and toughened ball screws specifically for injection moulding machines. Also featured on the NSK booth (Hall 7, Stand D12) will be a working demonstration of a condition monitoring system (CMS) with real-time vibration analysis displayed on a monitor.

2nd August 2017

Independent Automotive Aftermarket solutions at Equip Auto 2017

It has been announced that NSK will be making a debut appearance at the Equip Auto 2017 exhibition in Paris, 17-21st October. Present on booth 1 C 085 in pavilion 1, visitors to the show will find an informative display that supports NSK´s strategic decision from last year to enter the Independent Automotive Aftermarket (IAM). Based on the company´s position of strength as an OEM and first tier supplier, NSK´s IAM approach is to ensure that partners and garage owners become more profitable, efficient and effective.

19th July 2017

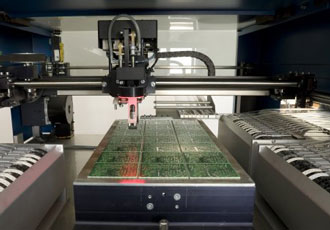

Mini linear guides bring higher dynamics to pick-and-place machines

In the semiconductor industry machines operate with cycle times of one second or less, therefore pick-and-place units must offer very high dynamic performance. A case in point can be seen at a manufacturer of chip-mounting systems, where NSK recommended a combination of its ball screw and miniature linear guide technologies to replace the existing linear motor and significantly increase dynamic capability.

14th July 2017

Low-friction ball bearings increase energy efficiency

Energy efficiency is increased and operational noise is reduced through the use of low-friction ball bearings in drive systems. Bearings of this type will also reduce heat generation, which in turn helps to extend service life. Based on concepts such as optimised raceway geometry and special sealing concepts, NSK has developed several series of ball bearings that offer significantly lower friction characteristics.

11th July 2017

Bearings save nearly €20k a year at biogas plant

NSK’s advanced moulded-oil deep groove ball bearings are used in the rotary screen of a biogas plant, and has seen a service life of more than double a normal bearing, which can help manufacturers save €19,200 per annum. Moulded-oil bearings feature lubricant that is embedded in a polyolefin resin, which prevents the penetration of liquid and particle contaminants to permit extended periods of maintenance-free running.

12th June 2017

Increasing service life for linear guides

A solution to short lifespan issues recently was needed from a sheet metal manufacturer as it was experiencing difficulties with the drive and guide elements on its automated welding systems. The linear guides for a robotic welding gun on one particular production line had to be replaced every two or three months. Due to the cost of replacement parts and maintenance time, as well as equipment down-time, the company turned to NSK to investigate and provide a proposal to address the problem.

30th May 2017

Replacing large rolling bearings requires precision and skill

Extremely large rolling bearings that are used in steelmaking equipment pose significant challenges when they need replacing with regard to the tools, team and strategy deployed. However, this task is not insurmountable, as NSK recently demonstrated in the overhaul of a converter at a major Scandinavian steelworks.

22nd May 2017

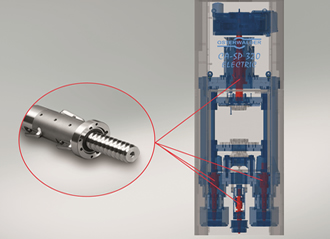

Ball screws offer greater dynamic load capacity

The newly developed S-HTF series ball screws from NSK offer more than double the service life and 1.3 times greater dynamic load capacity than the company's previous generation product. These performance attributes have been achieved thanks to the use of a steel material for the screw shaft that delivers an optimised combination of hardness and resilience.

17th May 2017

Linear Guides prove the solution for pick and place machines

With repeated failures of its linear guides, the established and reputable manufacturer of surface mount technology (SMT) pick and place machines turned to NSK for the solution. When identifying the source of the problem, NSK was able to recommend its NH Linear Guide series. Several thousand such units have since been supplied to the customer, with no premature failures reported.

27th April 2017

Larger sizes added to long-life ball bearing series

The long service life BNEQARTET deep groove ball bearings from NSK were introduced nearly two years ago, and now the company is adding new variants to the series with external diameters of up to 120mm. The bearings, which are manufactured from a special steel alloy, offer twice the service life of standard bearings.

6th April 2017

Roller bearings developed for continuous casting machines

A range of full complement cylindrical roller bearings for highly demanding steel industry applications has been introduced by NSK. NUB series bearings are designed to be particularly effective when used on the non-driven side of strand guide rolls; for example, in the straightening section of continuous casting machines.

3rd April 2017

Beware of the effects of counterfeit rolling bearings

A growing industry issue is counterfeit rolling bearings, as to the untrained eye, replica products are increasingly difficult to distinguish from genuine OEM bearings, which means that ever-more users are suffering from the consequences of using counterfeits. A case in point is highlighted at the Technical University of Dortmund (TU Dortmund), which was recently tasked with conducting research into enhancing the distillation process (the purification of liquids through repeated heating and cooling).

17th March 2017

First transmission-equipped wheel hub motor aims to improve safety

Successfully demonstrating the world's first transmission-equipped wheel hub motor, NSK has had a breakthrough development intended to improve the environmental performance, safety and comfort of vehicles. By expanding on the knowledge gained from the prototype demonstration, NSK are now looking to commercialise specific components, including the wheel hub unit bearing with integrated speed reducer, and a one-way clutch unit.

16th March 2017

Ball screws replace hydraulics in powder presses

The hydraulic drives from Switzerland-based Osterwalder are being replaced with servo-electric drives featuring NSK HTF series ball screws in its latest range of powder presses. As a result, users of the new systems can achieve a reduction in energy consumption of around 80% and produce pressed parts with far higher dimensional accuracy. This reduces the amount of finishing work, such as grinding with diamond wheels, and cuts process and material costs.

14th March 2017

The Bearing Doctor App can heal all your problems

A new free-to-download app has been launched by bearing manufacturer NSK, for maintenance engineers and technicians tasked with troubleshooting machinery or equipment featuring rolling bearings. The Bearing Doctor app for smartphones and tablets, is designed to help identify issues at an early stage, thus allowing preventative measures to be taken before costly failures occur.

23rd February 2017

Agricultural applications need to optimise bearing seals

When being used in agricultural machines, the seals of rolling bearings have to withstand extremely arduous operating conditions. This is why NSK has developed new seals for deep groove ball bearings that deliver a highly effective balance between the conflicting goals of sealing capability and low friction. The performance of the seals has been ably demonstrated in a series of demanding test simulations.

20th February 2017