Nord Drivesystems/Nord Gear

Address:

11 Barton Lane

Abingdon Science Park

Abingdon

OX14 3NB

United Kingdom

Abingdon Science Park

Abingdon

OX14 3NB

United Kingdom

Nord Drivesystems/Nord Gear articles

Displaying 41 - 60 of 78

Smart drive single handedly resolves blockages

Including an integrated PLC, intelligent drives from Nord Drivesystems come fully equipped to execute control sequences in customer applications. Featuring numerous sensor interfaces and extensive diagnostic as well as process control functions, they can detect blockages and in many cases independently restore normal operation, improving system availability and reduces servicing requirements.

14th September 2016

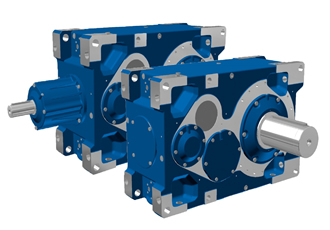

New two-stage helical bevel gearboxes with output torques up to 50 Nm

NORD DRIVESYSTEMS will be showing its latest series of slim two-stage helical bevel gearboxes in the form of a new smaller unit for output torques up to 50 Nm. The highly efficient helical bevel type units are now available and complement the line-up of worm gearboxes that are already available for small powers. Thanks to the ‘Unicase’ gear housing and large dimensioned bearings, the gear units are very robust and can withstand high radial or axial loads acting on the output shaft.

12th April 2016

Functional demonstration for materials handling industries

NORD Drivesystems will be showcasing a large fully functional conveyor technology demonstration rig that brings together a selection of its geared motors and decentralised frequency inverters and starters that are well proven for materials handling applications in packaging machinery and logistics industries such as baggage handling.

9th March 2016

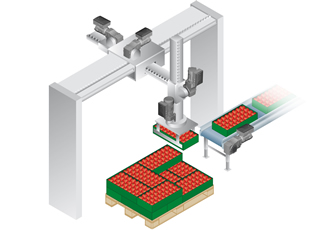

Smart Standard Drives provide servo performance and precision

NORD Drivesystems’ advanced frequency inverters and high efficiency geared motors can be combined to provide servo-level performance at very competitive costs when compared to traditional servo solutions. NORD offers a comprehensive range of cabinet, wall mounted and motor-mounted frequency inverters with optional POSICON position control for use with its IE2/IE3 asynchronous geared motors or permanent-magnet IE4 synchronous geared motors. Available with flexible choice of absolute or incremental encoder feedback, and with IEC 61131 programming support, POSICON offers a compelling solution for medium precision applications where multi-axis coordination, flying shear, master/slave synchronisation or positon/product registration is required.

26th November 2015

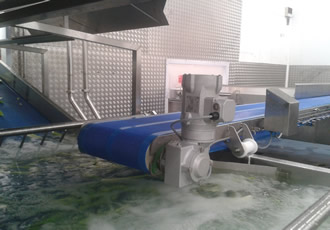

Increasing Reliability For The Food Processing Industry

From its base in East Anglia, one of the UK’s major agricultural areas, Ambit Projects Limited design and manufacture high quality automation equipment for handling, preparing and processing all types of foodstuffs with machines that are tailored to individual customer needs. The Company has gained a high reputation in this fast moving industry for providing innovative solutions that increase capacity through improved performance, reduce processing bottlenecks, decrease downtime and enhance final product quality.

28th May 2015

Customized solution for crane drive synchronization

What to do when the crane of your choice is no longer available? An Australian provider of overhead cranes fulfils all customer needs, even when the parameters are very particular. For this application, the challenge was to synchronize a new bridge crane with two existing ones. The German manufacturer NORD DRIVESYSTEMS configured the drives keeping in mind the end-users budgetary requirements.

20th January 2015

NORD solutions for the extended energy-efficiency directive

The European Commission has initiated a significant tightening of the energy-efficiency directive for electrical devices, leaving more users of drive technology faced with new challenges. By providing comprehensive information, fast, expert support, and suitable drive products, NORD DRIVESYSTEMS aims to enable machinery and equipment manufacturers to continue producing economically compelling solutions that comply with all regulations.

25th June 2013

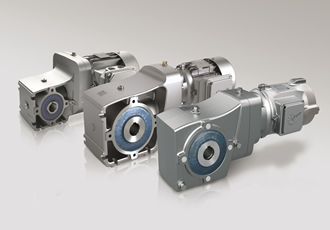

Clean drive solutions for food technology, conveyors, and beyond: Lightweight, hygienic helical bevel gear units

For hygienically demanding applications, NORD DRIVESYSTEMS supplies aluminium two-stage helical bevel gear units in five sizes with a maximum torque of 660 Nm that are easy to clean. The washdown design is based on smooth inclined surfaces, transitions with large radii without dead spaces, and requires no assembly covers.

18th April 2013

New SMI series worm gear units from NORD

NORD DRIVESYSTEMS now offers a new range of worm gear units in a robust, one-piece UNICASE housing in five sizes with a maximum torque of 427 Nm. New, larger output bearings allow users to choose increased shaft diameters than the previously available series. In addition, the large bearings ensure a much extended service life.

26th March 2013

NORD DRIVESYSTEMS UK gain ISO14001: 2004 Environmental Management System

NORD DRIVESYSTEMS’ UK sales and assembly facility has achieved ISO 14001: 2004 accreditation by LRQA following approval of its Environmental Management System. The internationally recognised EMS standard provides a framework for best practice for the efficient use of energy and raw materials along with many other important environmental factors such as waste reduction managed within its continuous improvement programme.

5th March 2013

Microsite food.nord.com is optimized for mobile devices: Quick overview of hygienic drive solutions

NORD DRIVESYSTEMS manufactures high-performance, cost-effective drive technology for the food and beverage industries that fulfills strict hygiene requirements. Especially developed for this area of industry, the drive manufacturer's microsite – http://food.nord.com – has now been optimized for mobile use (iPhone, Android smartphones, Blackberry etc.). An adapted layout ensures excellent readability and straightforward navigation.

19th February 2013

NORD DRIVESYSTEMS release new drive surface protection catalogue

NORD DRIVESYTEMS has released a new brochure presenting the wide choice of surface protection treatments offered across its comprehensive range of geared motors and drive units. The 8-page information resource covers the latest generation high-solid paint and powder coat finishes as well as NORD’s unique NSD tupH surface conversion treatment which provides stainless steel-like durability advantages for aluminium gear unit and geared motor frames.

14th February 2013