Mitsubishi

Address:

Gothaer Straße 8

40880 Ratingen

Germany

40880 Ratingen

Germany

Mitsubishi articles

Displaying 21 - 40 of 187

Easy IT connectivity for machine tools

Mitsubishi Electric CNCs has demonstrated support for umati machine tool networking technology at EMO 2019. The implementation of umati (universal machine tool interface), which enables machine tools to exchange and share information efficiently, has tremendous potential for optimising production.

14th November 2019

Plug-n-play robots for machine tools increase competitiveness

Faster time to market and increased production flexibility can be achieved using Mitsubishi Electric’s M8 Series CNC controllers with Direct Robot Control (DRC) functionality. Both the large touchscreen M800 and the M80 models offer DRC as standard. It allows machine tool operators to program and use robots quickly, direct from the CNC panel without specialist robot programming expertise.

14th October 2019

Introducing the range of high performance delta robots

Mitsubishi Electric has extended its MELFA articulated arm and SCARA robot offering to include a range of delta robots. These combine Mitsubishi Electric’s award-winning servo technology with the latest mechanicals from e-F@ctory Alliance partner Codian Robotics. This combination enables the user to achieve reliable performance in higher speed pick and place operations, with the advantage of simple set-up and programming from one the markets main automation brands.

16th September 2019

Predictive maintenance helps food and beverage companies

With any unscheduled down-time being a cause of major headaches for food and drink manufacturers, John Rowley of Mitsubishi Electric highlights how predictive maintenance can provide the solution and how easy it is to implement. With food manufacturers being continually squeezed on price by retailers and asked to fulfil orders for supply that can seem, at best, challenging and at worst highly unrealistic, improving productivity is a priority.

30th August 2019

Smart automation solutions increase productivity

In an increasingly competitive marketplace smarter machine tools can offer big advantages to production facilities such as increased flexibility, efficiency gains and reduced down-time. At EMO 2019 Mitsubishi Electric will be showing how these goals can be met with connected production systems, intelligent control systems, Edge Computing and partner solutions.

28th August 2019

Meeting the automation challenges of smart manufacturing

It is worth stating that implementing smart manufacturing is a very worthwhile exercise, successfully applying a level of smart manufacturing will bring greater efficiencies and flexibility to any given production process. It is also a significant step toward ‘futureproofing’ a production enterprise. That 'forward thinking' mind-set is essential when implementing smart manufacturing projects where intelligent machines, systems and networks are capable of independently exchanging and responding to information to manage industrial production processes.

19th August 2019

Industrial food cutting becomes a piece of cake

Mitsubishi Electric has assisted Western Mechanical Handling (WMH) to develop a fully automated inline cell for cutting and slicing food of any size and shape on the fly. The solution is based on Mitsubishi Electric’s MELSEC Q series high-performance PLC, plus system-matched components including HMI, variable speed drives and two MELFA articulated arm robots. The resulting machine maximises performance, flexibility and productivity for customers in the food sector.

8th August 2019

Explore the future of digitalisation with real industry insight

One of the world’s leading automation companies Mitsubishi Electric is hosting a national event where visitors can explore the very latest technology being applied in smart manufacturing and discover how leading companies from a variety of industrial sectors are navigating their path towards digitalisation.

8th August 2019

Mitsubishi Electric invests in Akribis Systems

Mitsubishi Electric Corporation has taken an equity stake in Akribis Systems, a Singapore based manufacturer of linear servo motors and linear stages,to strengthen its industrial automation solutions for the global market. Mitsubishi Electric, by integrating its servo systems and other industrial automation products with Akribis' product lineup, aims to meet increasing needs for high specification, high precision manufacturing.

7th August 2019

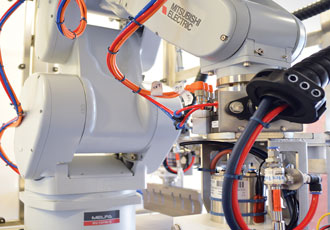

AI improves maintenance management for robots

As Industry 4.0 turns into a reality, businesses that are introducing more robots into the production environment will be able to benefit from increasingly efficient maintenance regimes. As with any asset, these critical machines will run at peak efficiency when operators have access to predictive maintenance tools. The latest predictive analytics solution supplied with Mitsubishi Electric industrial robots uses Artificial Intelligence (AI) as a key feature for optimisation.

6th August 2019

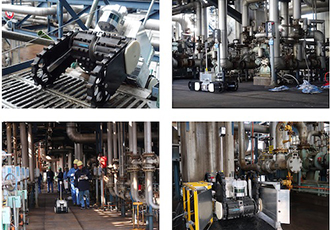

Test of explosion-proof plant inspection robot

A running test of the prototype EX ROVR, a plant inspection robot with explosion protection features to limit the danger of the robot itself igniting an explosion or fire from electric sparks or heat, even in areas with flammable gas, is being carried about by Mitsubishi Heavy Industries (MHI).

17th June 2019

Smart condition monitoring increases malt barley productivity

One of the UK’s largest producers of malted barley, Muntons has protected vital parts of their production process against unscheduled down-time by using the Smart Condition Monitoring (SCM) system from Mitsubishi Electric. Used to make beer, spirits and a range of popular foodstuffs, malted barley is produced in large batches where environmental conditions are critical to a consistent product.

17th May 2019

Convenient way to monitor inverters

A new app has been introduced by Mitsubishi Electric for iOS tablets and smartphones that provides convenient commissioning, maintenance, troubleshooting, parameterisation and monitoring support to company’s FR-F800E and FR-A800E inverters. Available from the Apple App Store, the Inverter StartApp addresses modern requirements to glean more information from manufacturing processes, with easier accessibility, and to be able to act on that information in a timely and convenient manner.

1st May 2019

New starting points for building a smart food factory

Food producers currently span the full automation spectrum, from huge volume beverage production and packaging plants to artisan food producers that do everything they can by hand. There is a large portion of the UK food industry however that sits between these two extremes and it has been slow to adopt smart factory technology.

25th April 2019

Energy saving in mines and quarries

Most mines and quarries contain a proliferation of electric motors, they vary in size and importance from large machines critical to site safety, to smaller examples that enable basic plant processes. Each one is drawing electricity and unless it is already part of a smart control solution, it could be contributing more towards energy and general cost saving.

By Trevor Herbert, Business Development Manager for Mitsubishi Electric Europe - Automation Systems Division

10th April 2019

Latest SCADA software platform increases scope

MAPS 4, the latest SCADA solution from Mitsubishi Electric for control and visualisation, extends connectivity options, adds user tools and increases the scope of its built-in functionality. The result is a software suite that can reduce the time taken for project development and integration, while also enabling users to realise Smart Factory objectives.

28th March 2019

141119.jpg)

mit100419.jpg)

280319.jpg)