German plant technology in great demand in Belarus

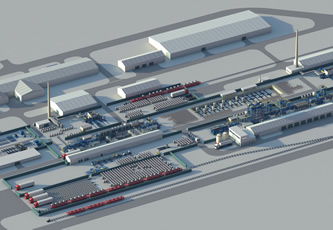

Supplying a plant complex for the production of tinplate SMS is helping Miorskij Metalloprokatnyi Zavod (MMPZ-group) located in Miory in the Republic of Belarus. The contract became effective in early 2017. The new works will initially have an annual capacity of 150,000 tonnes. Provisions will be made to increase the capacity to up to 240,000 tonnes at a later stage. The first plant units are scheduled to start producing in the second half of 2018.

SMS group will supply a reversing cold mill, an electrolytic cleaning line, a batch-annealing plant, a combined double-reducing and skinpass mill, an electrolytic tinning line and two packaging lines – one for sheet packs and one for coiled product.

The rolling and strip treatment plants will be equipped with X-Pactautomation systems.

The new production complex is being erected in the north of Belarus. MMPZ-group plans to use the new facilities mainly for the production of tinplate for the packaging industry and of cold-rolled sheet. In order to be able to flexibly respond to future market demands, the plants will also be designed to produce non-coated sheet in Commercial Quality (CQ) and Drawing Quality (DQ) grades. MMPZ-group plans to export the main part of the products to Russia, other CIS markets and the EU.

The reversing cold mill with CVCplus technology features SMS group’s latest high-performance design for cold rolling mills. The mill will use very slim work rolls, allowing high reductions per pass to be achieved with fairly low rolling forces, making operation of the mill highly efficient.

In addition to the CVCplus technology, features such as work roll and intermediate roll bending, multi-zone cooling and the DS system will guarantee that the required quality in terms of strip thickness, flatness and surface quality is reliably achieved.

Downstream of the rolling mill, the strips will pass through the electrolytic cleaning section. Designed for low media and energy consumption, the cleaning section will achieve a very good surface quality of the cleaned strips.

Cold strip to be used as packaging material must be recrystallisation annealed in order to obtain the ductility necessary for that application. The ten batch-annealing furnaces, which will anneal and cool the coiled strip in a specified procedure, will be able to accommodate up to 4.8m high stacks of coils of a maximum weight of 125 tonnes.

The combined twin-stand double reducing and skinpassing mill will process the strips either by skinpassing or by double reducing and skinpassing depending on the required strip grade.

The plant for MMPZ-group will be able to produce double reduced strip in thicknesses down to 0.10mm for the manufacture of special tinplate products. It will also be suitable for skinpassing CQ and DQ tinplate in thicknesses between 0.35-1.00mm.

In the electrolytic tinning line, the extremely light-gage steel strip will receive a very thin tin coating as corrosion protection, making it a high-grade tinplate product. MMPZ-group has decided in favour of a process based on soluble tin anodes, as this process provides a series of economic, ecological and process-technological advantages.

These include lower tin consumption and stable process conditions, which in combination with exact process control guarantee a high quality of the final product. Numerous measuring devices installed along the entire line and the coating layer thickness gauge will ensure constant monitoring and control of the process.

The coil packaging line will be designed to handle up to four coils of 25 tonnes weight per hour. The sheet packaging line will pack stacks of cut-to-size sheets of up to 1,200x1,250mm in size.

Similar articles

More from SMS Group

- Two converter shops aims to boost steel production in Vietnam 2nd August 2017

- Tolerance improvements with new straightening machine 25th July 2017

- Iranian steel plant commences production 24th July 2017

- Modern drive concepts for closed-die forging presses 3rd July 2017

Write a comment

No comments