CGTech to showcase VERICUT Programming and Simulation at Farnborough International 2012

2nd May 2012

Source:

CGTech Ltd

CGTech will be exhibiting at Farnborough International 2012 on stand D100 in Hall 1 on July 9th – 13th 2012. The stand will feature the latest versions of CGTech’s VERICUT software products for both Machine Tool Simulation and Automated Fibre Placement (AFP) programming and simulation. In addition CGTech will present a new product for programming and simulation of Automated Drilling and Fastening machines used for airframe assembly.

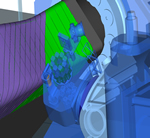

VERICUT Drilling and Fastening is a new software application for simulating and programming auto-drilling and fastening machines. These machines are used to assemble large aero-structures and it is essential to avoid programming errors and collisions at such a late stage in the aircraft manufacturing process. VERICUT allows the user to programme drilling and fastener assembly operations in a virtual machine tool environment and provides simulation to check for a variety of potentially disastrous error conditions. Like all VERICUT software the new module interfaces to leading CAD/CAM/PLM systems and is independent of the assembly machine manufacturer.

Throughout the show, CGTech will be demonstrating VERICUT Composite Applications: VERICUT composite Programming (VCP) and VERICUT Composite Simulation (VCS).

There will be demonstrations of projects that highlight the implementation and use of machine independent off-line NC programming software for AFP machines. Current customer projects to be highlighted include: a large one-piece fuselage barrel on an Electroimpact multi-machine AFP fabrication cell; a U-channel structure on a 7-axis mTorres AFP machine; and aircraft skin panels and experiments using an AFP head mounted on a 6-axis robot.

CGTech will also be previewing version 7.2 of it's market leading VERICUT CNC machine simulation and optimization software. VERICUT simulates all types of CNC machining, including aerospace processes such as multi axis milling, drilling and trimming of composite parts, water jet cutting, robotic and mill/turn machining. VERICUT is used to simulate CNC machine Tools from all leading brands including Makino, Starrag Heckert, Heller, Matsuura, Mori Seiki-DMG and Yamazaki Mazak.

VERICUT runs standalone, but can also be integrated with leading CAD/CAM/PLM systems including Dassault Systemes Catia, Siemens NX, PTC, Delcam PowerMill and Open Mind Hypermill.

Throughout the show, CGTech will be demonstrating VERICUT Composite Applications: VERICUT composite Programming (VCP) and VERICUT Composite Simulation (VCS).

There will be demonstrations of projects that highlight the implementation and use of machine independent off-line NC programming software for AFP machines. Current customer projects to be highlighted include: a large one-piece fuselage barrel on an Electroimpact multi-machine AFP fabrication cell; a U-channel structure on a 7-axis mTorres AFP machine; and aircraft skin panels and experiments using an AFP head mounted on a 6-axis robot.

CGTech will also be previewing version 7.2 of it's market leading VERICUT CNC machine simulation and optimization software. VERICUT simulates all types of CNC machining, including aerospace processes such as multi axis milling, drilling and trimming of composite parts, water jet cutting, robotic and mill/turn machining. VERICUT is used to simulate CNC machine Tools from all leading brands including Makino, Starrag Heckert, Heller, Matsuura, Mori Seiki-DMG and Yamazaki Mazak.

VERICUT runs standalone, but can also be integrated with leading CAD/CAM/PLM systems including Dassault Systemes Catia, Siemens NX, PTC, Delcam PowerMill and Open Mind Hypermill.

Similar articles

More from CGTech Ltd

- Achieving process optimisation through simulation 27th May 2020

- VERICUT V8.2 users get the heads up (display) 16th November 2018

- CGTech to showcase aerospace applications at Farnborough Airshow 15th May 2018

- VERICUT composite applications software Version 8.1 released 4th April 2018

Write a comment

No comments