Addressing the challenges of Industry 4.0

As the digital revolution reaches a turning point, it entails a fusion of technologies that are blurring the lines between the physical, digital, and biological spheres and can be fundamentally characterised by their velocity, scope, and overall impact. It will affect all aspects of human life, including the time we devote to work and leisure, and how we develop our careers and skills.

One area where this change is profoundly felt is on welding, since the production requirements within Industry 4.0 demands more complex and advanced welding processes, with high performance, productivity, and quality of the welds.

From a professionals’ qualification standpoint, in order to ensure that the future workforce is prepared for the challenges of industry 4.0, a number of issues need to be addressed. The fourth industrial revolution is pushing traditional education systems to its limits and shedding a light on its shortcomings, since in its scale, scope, and complexity, the transformation brought forward will be unlike anything humankind has experienced before and is evolving at an exponential rather than a linear pace.

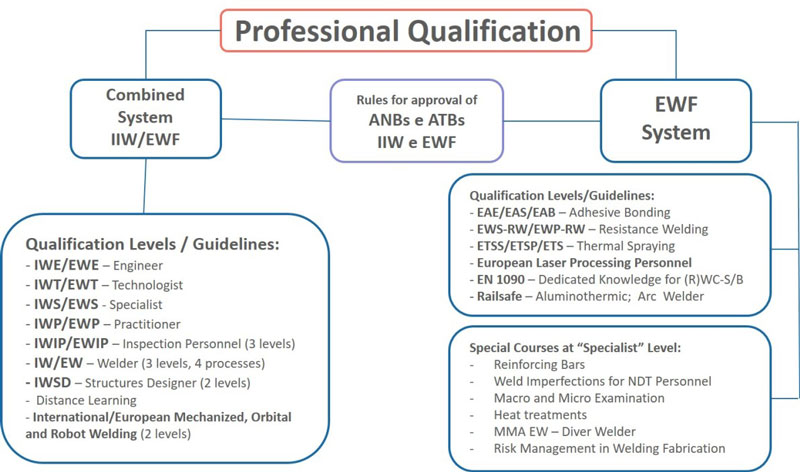

The issues to be addressed range from the need to streamline retraining and reskilling, to ensure transferability between traditional education systems and technical education, to integrate modularity on the qualifications systems and, lastly, to align industry’s qualification systems with the European Qualifications Framework, hence ensuring a more qualified and mobile workforce within EU. And EWF is spot on, providing the right qualification system, at the right time, and for the professionals that need it. Its success can be better assessed by the fact that it has kept evolving, adding courses that match the changes sweeping through the industry and reaching out to new audiences since it launched its system for welding professionals in 1992. Until now, more than 300,000 diplomas have been awarded, and the EWF guidelines are seen as a stamp for 'Quality' and are referred to in several standards, namely in the field of welding technology.

The cornerstones underlying the long term vision and strategy of EWF are the following:

- Ensure that the training and qualification System is updated to comply with technical innovation and industrial demand;

- Develop new qualifications in line with technological and industrial advances;

- Provide a pathway for continuous professional development for professionals in manufacturing;

- Create flexible pathways for continuous professional development;

- Ensure the quality of the EWF diplomas, by running a rigorous quality assurance system in the countries worldwide that are using the EWF System.

One key focus area needed to bring this vision to life is the need for skills and qualifications transferability. The two existing pillars of knowledge acquisition are the traditional education systems learned at Universities and the technical training given for specific jobs. The current disconnect implies that a qualified technician will not have their qualifications recognised in the traditional education system, which basically means that transferability of knowledge is not effectively being applied, hinders industry’s growth and creates unnecessary barriers to improving workforce qualification. EWF system addresses this shortcoming by providing a pathway for the recognition of qualifications in the countries that are already engaged with the system and is actively pursuing opportunities to reach out to new heights.

Looking ahead, EWF is also embracing e-learning options, namely a modular approach to qualifications and trendier learning opportunities such as online learning. On the former, and leveraging its knowledge, EWF is developing a modular approach to its qualification system, enabling professionals to pick and choose the most appropriate qualifications to achieve the required certification, thus enabling further flexibility of the workforce in response to changing industry’s requirements.

Lastly, since mobility is becoming increasingly relevant to match job opportunities with the workforce and provide additional competitiveness to European companies, EWF has been hard at work developing a lighthouse project to align the Welding Qualification System to the European Qualification Framework (EQF), through the National Qualifications Framework of each individual country. Once completed, and beyond creating opportunities for manufacturing professionals within Europe, the results of this project can be used for benchmarking with other areas from the manufacturing sector.

A lasting success story

In 1992, the member countries of EU where welding courses were offered started a process of harmonisation of the content of education and the implementation in terms of course’s syllabus and hours of training allocated to each module. By using a single syllabus for each level of the training course and a harmonised system for examinations, the same qualification could be awarded in any country. A success story was started that is still unfolding and retains its unique ability to innovate and lead in learning methodologies.

The system’s success lies in the fact that it is supported by a robust and transparent quality system that is widely accepted by the complete chain of individuals and organisations involved, from training institutions to national certification bodies, companies, trainers and trainees. Once the system was set and established, and after negotiations with the International Institute of Welding (IIW), non-European countries were added. This has led to the creation of a network that currently comprises 46 countries using the EWF/IIW qualifications and certifications, totalling 44 ANBs (Authorized National Bodies), 683 ATBs (Authorised Training Bodies). The network also includes 55,000 companies worldwide.

The Authorised Training Bodies are approved and supervised by the ANBs for implementing the EWF/IIWQualification courses, which combine both supporting knowledge and application experience, in a close relation with industry and their needs. Special courses were developed providing a specific education on emerging technologies, such as laser welding or adhesive bonding.

An important aspect that made this system so widely accepted and recognised relies on the quality assurance system. There is a set of highly qualified quality auditors that perform external audits to both ANBs and ATBs and check the consistency of the full chain, from course processes and organisation enforcement to diploma issuing, including training and trainees and trainers’ assessments.

Similar articles

More from European Welding Federation (EWF)

- Addressing the challenges of Industry 4.0 5th July 2017

Write a comment

No comments