Pump developed to be suitable for all industrial occasions

One of the most common hydraulic pumps is the axial piston, which is used in many industrial applications as well as off-highway and mining. Throughout the industrial workplace, hydraulic pumps provide a great deal of motive power, efficiently translating the rotary motion of a prime mover into hydraulic oil flow that can be easily routed and used for a vast range of tasks.

Engineering Manager at Oilgear in the UK, Jim Cairney, explains the principles and applications of the axial piston pump.

Hydraulic pumps come in many shapes and sizes, but one of the most versatile is the axial piston pump, which can be arranged as a pump or a motor, depending on the application. Coupled with a choice of control mechanisms, the axial piston pump can be applied to a myriad of tasks. The basic design provides an efficient delivery of power which has led to an increasing number being specified in favour of fixed displacement gear or vane pumps.

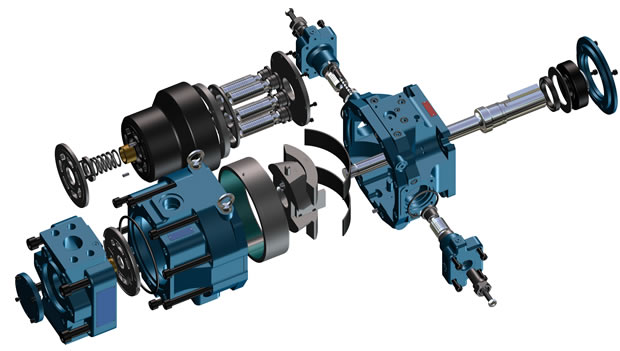

At the heart of the axial piston pump is a group of finely machined pistons that are fitted inside a round cylinder barrel which rotates. In a fixed displacement pump the cylinder barrel is inclined at an angle to the drive shaft so that as the cylinder rotates one revolution, the pistons complete a full stroke. The total displacement of the pump is determined by the size and number of pistons as well as the length of the stroke, which is determined by the angle of inclination.

In a variable displacement pump, the pistons are attached to an angled plate, known as the swash plate, so that as the assembly rotates the pistons reciprocate, parallel to the driveshaft. By changing the angle of the swash plate, the displacement is adjusted. In both cases the oil flow is controlled by the valve plate which directs low pressure oil to the pistons on the suction stroke and the pressurised oil to the discharge port.

As a hydraulic pump, these components are used to provide the flow which in turn can actuate hydraulic cylinders, valves, motors and brakes. However, the principle action of the pump can also be reversed with the flow being fed into the component which in turn will rotate the driveshaft; the pump has then become a hydraulic motor.

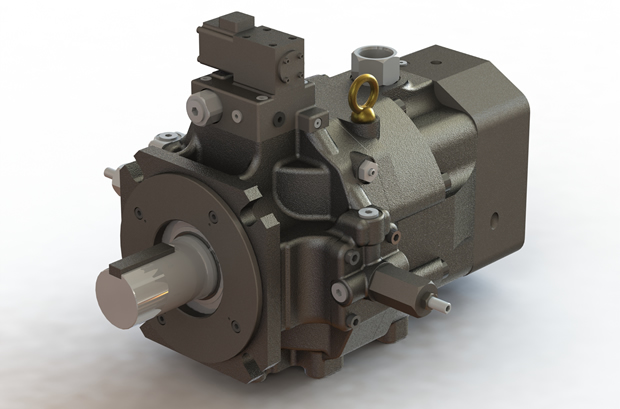

While the essential principles are very similar in all hydraulic axial piston pumps, the finer details, such as the precise construction, materials, tolerances and control features are what make each pump design unique and influence the suitability of the component for a particular application.

One example would be the use of a hydrodynamic bearing, which is a feature of all Oilgear’s axial piston pumps. This allows the rotating barrel to ride on a thin film of oil, without the need for conventional bearings, which limit the operational cycle of many other pumps. In fact, because the input shaft bearing in Oilgear pumps does not have to support any of the loads induced by the pressure, it will last many times longer. When it finally does require replacement, it can be changed without taking the pump apart, saving time and improving productivity.

Flow rate, maximum operating pressure and control options are key factors in selecting the suitability and efficiency of a hydraulic pump in an application. Usually the pump can be paired with a choice of control features to deliver the required combination.

Pressure compensation control uses a cylinder connected to the swashplate to adjust the displacement of the pump as the pressure in the output line approaches a set value. In some cases it may be necessary to combine pressure compensator control with load sensing or with a horsepower limiter depending on the application. Hydraulic systems that employ more than one pump can also have different control types on each pump which, allow different application requirements to be met by the most suitable method without needing separate electric motors.

Identifying the most appropriate control method is just part of the pump selection process when developing a hydraulic system. In many cases the pump selection will use an existing configuration which has been developed to suit a number of common applications. Maximum flow rates and operating pressures are used to determine a specific model while the control characteristics are selected to give the best operation while keeping power input within available limits.

However, certain situations may require a very specific solution, such as a recent development that was created by the Oilgear engineers in Leeds, UK. Having been approached to deliver a hydraulic pump for a steering system on a ship, Oilgear realised that the very specific flow rate required for this application fell between two models of its PVV range of pumps.

It would have been possible to meet the flow requirements by down-rating an existing model, but this would have been a compromise that, in this situation, was not acceptable. As a result, the Oilgear designers set about creating a new model, the PVV-355, which would precisely meet the specification of the client. The creation of this new model has extended the original model range and is now available for general use.

While the majority of hydraulic applications involve pressurised mineral oil, there is a growing requirement for systems that operate with other fluids, especially low viscosity fluids with high water content and fire resistant fluids. Designing pumps for these applications raises a number of issues, with lubrication, or rather the lack of it, being a key issue. Without the natural lubricating properties of oil, issues such as bearing design, piston wear and pump sealing have to be reassessed.

Every industry in terms of hydraulic operation will face its own challenges, yet all have the common goals of improved performance and minimal down time. This is achievable by combining experience and design expertise to identify the most appropriate design combination, even if it means a new design, of pump and control system with the application in question.

Similar articles

More from Oilgear

- Proper servicing will make hydraulics run and run 8th June 2017

- Sports stadia reach new levels of automation thanks to hydraulics 31st March 2017

- Getting a fresh take on subsea hydraulic control 13th February 2017

- Innovation and performance for hydraulic systems 19th January 2017

Write a comment

No comments