Sulzer Ltd

Address:

Zürcherstrasse 14

8401 Winterthur

Switzerland

8401 Winterthur

Switzerland

Sulzer Ltd articles

Displaying 1 - 20 of 93

Construction of Sulzer’s new Birmingham Service Centre on track

Work on Sulzer’s new service centre in Birmingham, UK, is continuing to schedule. As planned, the building is now watertight, and attention is turning to the internal construction of the workshop area and the offices. Customers can expect the new facility to be open towards the end of autumn 2020, and in the meantime, the existing service centre will continue to work at full capacity.

8th September 2020

Electrical distribution powered up for holiday period

Keeping machinery operational is vital to maintaining productivity and being able to complete maintenance work during natural down-time, such as weekends, can make a significant difference. The installation of a new electrical supply for a food manufacturer on the Wirral, UK, needed to be completed quickly, so they called in Sulzer to get the job done.

1st July 2020

Rapid reverse engineering

Many industrial processes rely on compressors for a host of essential tasks, from powering machinery to squeezing industrial gases for storage and transportation. When one of its main compressors failed, a company in the Philippines faced high costs and the prospect of a long wait for a critical replacement part. That’s when it turned to Sulzer for help.

18th December 2019

The future of the oil and gas sector is now

Sulzer will be presenting key technology trends and innovations in the energy sector on Stand 6150 at Abu Dhabi International Petroleum Exhibition and Conference (ADIPEC) 2019. As a one-stop-shop for advanced components, solutions and services for oil and gas separation processes, the company is leading the industry into the future.

25th October 2019

Celebrating increased diversities in STEM industries

Sulzer strives to promote and maintain an inclusive, diverse and empowering working environment. This has been recognised by the Empowering Women in Industry awards in the nomination of six of Sulzer’s employees as finalists across nine of the eleven categories. The conference and awards gala, taking place on 26th September in Chicago, IL, US, celebrates the excellence of female professionals in a male-dominated industry to promote gender equality.

25th September 2019

Rapid parts for rotating equipment

Recent advances in the design and manufacture of spare parts have led to a significant reduction in the time taken to create replacement components for breakdown situations or for those that have reached the end of their service life. Digitalisation and new manufacturing techniques have paved the way for a dramatic improvement in lead times.

2nd September 2019

Emergency weekend hospital repair saves operations

Hospitals, especially those with designated major trauma centres, depend on their emergency theatres to deliver life-saving treatment. So, when an air handling unit (AHU) needed an overnight repair, Sulzer engineers were reportedly able to complete the project and ensure no operations were cancelled.

8th August 2019

Investing in the engineers of the future

Engineers collect a vast array of skills and experience through their working lives and it is essential that these are passed onto the next generation to become tomorrow’s engineers. Sulzer has a very long and distinguished history in delivering engineering solutions. In Southampton there is a strong focus on engineering and that is being supported by its continued investment in both apprentices and equipment.

25th July 2019

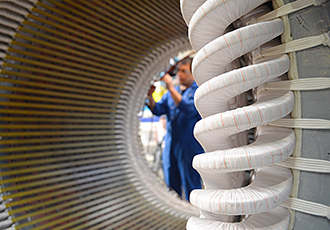

Improving quality of high voltage coil manufacturing

Reducing the time to complete a repair or refurbishment of high voltage equipment minimises downtime and increases productivity. Sulzer is continuing to invest in its design, manufacturing and testing facilities to enable faster turnarounds for customers. To keep up with growing demand, Sulzer is also increasing the capacity of its Falkirk Service Center, where the test-bed load capacity has been doubled.

3rd April 2019

Fast rotor repair improves efficiency

When a damaged steam turbine rotor needed to be repaired, a power generation plant in Indonesia turned to Sulzer. Rather than wait for a new rotor from the original equipment manufacturer (OEM), the plant opted for a repair that took only sixteen weeks. This swift and effective repair also managed to achieve an eight percent improvement in efficiency.

28th March 2019

Flying large rotors in for fast repair

A steam turbine rotor has been airfreighted to Sulzer’s service centre for fast repair, as 150MW generators provide power for around 100’000 homes so minimising down-time is essential to keeping the lights on for the local population. For one power plant in the Philippines, the swift repair of a steam turbine rotor was essential, so it was airfreighted using one of the world’s largest cargo planes, to Sulzer’s service centre in Indonesia, where the repairs were completed within eight weeks.

1st February 2019

Flying large rotors in for fast repair

150 MW generators provide power for around 100’000 homes so minimising down-time is essential to keeping the lights on for the local population. For one power plant in the Philippines, the swift repair of a steam turbine rotor was essential, so it was airfreighted using one of the world’s largest cargo planes, to Sulzer’s service center in Indonesia, where the repairs were completed within eight weeks.

23rd January 2019

The BLUE BOX for IoT analytics wins Industry 4.0 award

Sulzer’s BLUE BOX IoT Advanced Analytics has won the Gold Certificate Industry 4.0 at the Swiss Digital Economy Awards in the category Highest Digital Quality. BLUE BOX uses existing pump data to cut costs in pump operation and maintenance considerably. The Swiss Digital Economy Awards are presented by the industry association SwissICT, the Association of Swiss Internet Companies Simsa and the specialist publisher Netzmedien.

19th December 2018

Two-component battery powered dispenser for cartridges

The COX ElectraFlow Dual Ultra has been specifically designed for the professional and specialist trade users across all industry sectors who demand a reliable and high-performance two-component dispensing tool. The fully integrated application system features cordless technology powered by the latest 18V lithium-ion batteries and chargers.

16th November 2018

Pump and turbine technology reaches a new level

Sulzer is inviting visitors to this year’s event to view and discuss the innovations that are shaping the sector. By attending the technical sessions and visiting stand 1719 at Turbomachinery & Pump Symposia (TPS) 2018, delegates will be able to learn more about Sulzer’s comprehensive offering for pumps and rotating equipment, including the latest innovation in additive manufacturing and digital technologies to improve pump performance.

22nd August 2018

Solutions for pumps and rotating equipment at POWER-GEN Asia 2018

As one of the leading pump manufacturers and independent repair specialists, Sulzer plans to deliver innovative products and repair solutions for the power generation sector. At this year’s event, visitors will be able to discover some of the latest developments in pump design, turbine blades and high-voltage coil testing.

15th August 2018

Repairing rail generators to hit four year reliability target

Maintenance and repair projects within the rail industry are managed by tier one contractors to provide operators with a fixed cost project that enables them to accurately forecast annual repair bills. This type of contract requires flexibility and high quality repairs to provide customers with reliability.

Author: Mark Taylor, Service Centre Manager at Sulzer’s Nottingham Facility

23rd July 2018

Investing in UK high voltage coil manufacturing

As part of a recent UK investment program, Sulzer has built and equipped a dedicated in house test and development laboratory for high voltage coils. Other aspects of the program include upgrading key items of manufacturing equipment at the company’s Birmingham based Centre of Excellence for coil design, manufacture and supply.

23rd July 2018

Larger capacity in high voltage testing improves repair times

The testing of performance on high voltage motors and generators is usually carried out to determine benchmark data following a major repair. However, increasingly, customers are requiring this information as part of a problem diagnosis or to verify performance figures for a component when its essential data has been lost.

7th March 2018

Product Centre Updates

2024 World Battery & Energy Storage Industry Expo (WBE)

8th August 2024

China 1st and 2nd Floor, Area A, China Import and Export Fair Complex

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)