Bauer Gear Motor GmbH

Address:

Eberhard-Bauer-Strasse 36-60

Esslingen

73734

Germany

Esslingen

73734

Germany

Bauer Gear Motor GmbH articles

Displaying 1 - 20 of 24

Keeping water treatment systems running through flood conditions

It started a long time before the industrial revolution, manufacturers extracting water from local rivers and streams, and the process is still commonly used today, in applications from energy generation to paper making. Unlike their forebears, however, modern systems inevitably include various treatment processes to ensure the extracted water meets appropriate quality, safety and process control standards.

5th March 2018

What role do motors and drives play in the water industry?

One our most vital resources, but one that we also tend to take for granted, is of course, water. For the water industry the processes that are required to maintain this service are numerous and provide many challenges in terms of efficiency and reliability. One of the most crucial components within the water treatment and delivery process is the humble electric motor, which along with its associated drive systems, provide the power necessary to keep the cycle in motion.

22nd June 2017

Are motors the missing puzzle piece in drive train efficiency puzzle?

Just ten years ago, headline efficiency figures could only be dreamed of, now manufacturers are chasing them, fuelled by the introduction of more stringent IE efficiency classes. It's obviously a positive thing for the industry, but it makes you think is motor efficiency just the tip of the iceberg?

1st September 2016

Bauer delivers efficiency for Pharmaceutical sector

Every industry aims to reduce costs and improve efficiency, but for some sectors this can prove to be more of a challenge. For those involved in the hygienic sectors, Bauer Gear Motor has not only developed market leading technology but also designed it to meet the requirements of both clean and potentially explosive atmospheres.

10th May 2016

HiflexDRIVE the flexible, efficient and clean drive solution

Geared motors have offered solutions to a number of challenges in a variety of industrial sectors for many years, and now, with ever increasing pressure to improve efficiency and reduce costs, more innovative and flexible solutions are being created. At the forefront is Bauer Gear Motor, which has already created a super premium efficiency (IE4) permanent magnet motor, and is now offering high efficiency geared solutions that can operate reliably in hygienic environments, where regular washdowns are a necessity.

25th February 2016

Embracing efficiency regulations can deliver cost savings with smart motor specification

The introduction of IE3 regulations and the anticipated arrival of IE4 presents an opportunity for businesses to embrace the latest in electric motor technology and also appreciate the cost savings that can be made. Manufacturers have developed new designs that will go beyond the required efficiency levels and enable operators to achieve significant savings in running costs.

18th December 2015

Bauer Gear Motor hosts energy efficiency technology forum

Electric motors are estimated to consume 70% of all the energy used in industry. Bearing this in mind, it’s no small wonder that there is an ongoing process of legislation requiring new technologies to adhere to ever higher standards of efficiency. Bauer Gear Motor offers a wide range of energy efficient solutions that meet current IE2, and future IE3 and IE4, regulations; it recently hosted a technology forum to help its customers understand the latest developments in the industry and discuss the best practices for maximising energy efficiency in the drive train.

1st December 2015

Bauer delivers IE4 savings for hazardous chemical process

Improving the energy efficiency ratings of electric motors is a worldwide goal, but exemptions in the regulations mean that for applications in potentially explosive atmospheres there is no obligation to implement the latest technology. However, for one oleochemical processing company improving energy efficiency is an important objective, which led it to consult with Bauer Gear Motor when a number of ATEX motors needed to be replaced.

28th July 2015

Bauer delivers substantial energy savings for pharmaceutical production

Production processes that run 24/7 need reliable and energy efficient drive systems to maintain a cost effective process. For one pharmaceutical manufacturer the drive for efficiency led it to replace some existing equipment with the latest IE4 electric motor technology from Bauer Gear Motor; reducing the kW power size by 60% whilst also reducing the weight and improving overall drive efficiency.

30th June 2015

Integrated design concept for drive solutions on bulk material handling equipment delivers substantial improvement in efficiency

When it comes to bulk materials handling, geared motors are used to power a wide variety of handling equipment from pumps to conveyors and bucket elevators. Different materials and operating conditions mean that each application can pose an individual challenge requiring expertise and a wide range of solutions in order to guarantee both product flexibility and universal reliability, real-world gains in efficiency however can only be achieved through an integrated design approach.

23rd June 2015

Bauer opens flagship production facilities to halve lead time, even for engineered solutions

Tuesday 5th May marked the official opening of the new Bauer production facility at the company headquarters in Esslingen. During the day, guests heard from Bauer’s M.D. as well as the Lord Mayor of Esslingen and CEO of Altra Industrial Motion, Bauer’s parent company. Guests heard how the facility will act as the flagship for Bauer’s new production concept, which increases the flexibility of the company’s ability to deliver engineered solutions for all applications on extremely short lead times.

7th May 2015

Overhead conveyor powered by Bauer improves productivity for bottling plant

While forklifts are excellent tools for transporting heavy pallets from place to place, they can also pose a very real risk to employee safety and cause damage to stock; this is especially true in an extremely busy working environment. One leading Swiss drinks manufacturer found that its bottling plant was so busy that driver error was having a real impact on productivity. Fortunately it was able to reduce operating costs and increase productivity by installing an electrical overhead conveyor (EOC) with vehicles powered by Bauer Gear Motor.

18th February 2015

Integrated and flexible design concept for drive technology in marine applications

The marine environment poses a number of challenges for those who design vessels and the equipment which is used on board. As equipment gets larger so the demands for more efficient systems increase as well; all the while having to contend with the inhospitable environment encountered at sea. To deliver a reliable and efficient product, while still achieving the requirements and specifications of the industry, demands an integrated and flexible approach from designers.

18th February 2015

Prepared for 2015's motor efficiency standards?

Efficiency regulations for electric motors will apply in Europe from January 1st 2015, whereby any installation using a 7.5-375kW motor must use either an IE3-rated or IE2 motor installed with a Variable Frequency Drive (VFD). Aimed at improving the overall efficiency of the installed equipment across Europe, the regulation is supported by EN50598, a standard which benchmarks the efficiency ratings of electric motor drives.

22nd December 2014

Motor and drive efficiency – A collective approach for better results

Efficiency, reliability and total cost of ownership are all terms that are at the forefront of engineering considerations, however looking at items of equipment on an individual basis may not deliver the maximum benefits. By looking at the wider picture and combining the best technology from individual areas it is possible to achieve much more significant savings and efficiencies.

28th October 2014

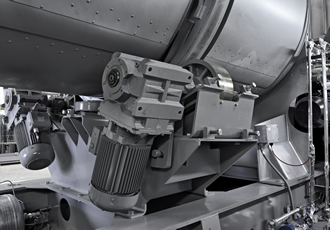

Gear motors key in steel mill overhead crane series

When Kranbau Köthen was commissioned to develop a new series of cranes for use in the scrap yard of a global steel producer’s mill in Luxembourg, it turned to gear motor specialist, Bauer, part of Altra Industrial Motion. Looking at all the issues of the Kranbau project, engineers at Bauer developed a solution, based on modified versions of their BK series of bevel gear motors. BK80 models were identified as the best choice for the cranes’ travel drives and BK90s for the trolley drives.

26th September 2014

Altra supports Bauer Gear Motor with €10m investment

Bauer Gear Motor, now a part of Altra Industrial Motion, is investing in business growth with a new manufacturing headquarters in its home town of Esslingen, Germany. Altra will be investing over €10million in the new manufacturing headquarters, the bulk of which will be spent on an additional production building for producing gear motors and the construction of a new office building with conference rooms.

12th August 2014

Bauer Gear Motors launches the world's first Ex-approved permanent magnet synchronous motor

Bauer Gear Motor, has launched the world's first Ex rated, IE4 Super Premium Efficiency motor. Taking Ex rated motors to the highest level of energy efficiency, the new S Series is the latest development to Bauer's PMSM (permanent magnet synchronous motor) range. An IE4 rating is the highest energy efficiency that can currently be achieved within motor technology, making the S Series the world's most efficient motor for use in explosion hazardous areas.

24th June 2013