Integrated design concept for drive solutions on bulk material handling equipment delivers substantial improvement in efficiency

When it comes to bulk materials handling, geared motors are used to power a wide variety of handling equipment from pumps to conveyors and bucket elevators. Different materials and operating conditions mean that each application can pose an individual challenge requiring expertise and a wide range of solutions in order to guarantee both product flexibility and universal reliability, real-world gains in efficiency however can only be achieved through an integrated design approach.

Bauer Gear Motor is working hard to satisfy industry demands with an expanding range of quality drive solutions available in a variety of configurations, including the ability to integrate the drive into the machine design, all of which can be arranged to meet specific client requirements and make substantial improvements in efficiency.

OEMs require rugged-duty geared motors for use on a variety of applications within their plants and Bauer is setting new standards for the future of design in the area of bulk materials handling equipment. The design process for a drive solution requires a flexible approach which can use the experience and engineering knowledge of industry experts and is also supported by a wide product range that can be developed into a bespoke package.

Conveyors and elevators are used across the mining, cement, asphalt and construction industries and can vary enormously in size from smaller mobile plants to vast fixed installations. For manufacturers of such equipment, it is essential that the drive package will deliver reliable service, but in addition it must cope with overloading as well as the harsh local environment. Energy efficiency however is also vital.

With increasing energy costs, efficiency is an important factor, with many manufacturers concentrating on the electric motor and speed control method to deliver savings, whereas the mechanical aspect of the drive can actually deliver the largest savings. Bauer is able to deliver these compound savings using a combination of modular products, in-house engineering and partnerships with system expertise. The greatest savings, can be made by optimising the mechanical efficiency of the drive system and it is this area that Bauer is leading the way with its new ‘design concept’.

André Bubolz, Director of Industrial Drive Applications for Bauer, comments:

"Within any drive system there are potential energy savings to be made, but we have found that improving the motor efficiency will only realise 10% of the maximum potential savings available, while changing to electronic speed control addresses a further 30%. Bauer has a range of standard efficiency class motors right through to super efficient IE4 class PM motors for maximum energy saving in continuous or heavy duty cycle applications.

“Addressing the motors and inverter drive however leaves a further 60% of the potential savings to be gained by improving the mechanical aspect of the drive. Bauer has the expertise to engineer the complete drive package, but it is the mechanical section which holds the key not just in terms of the flexibility and reliability of the design, but also in improved efficiency.

"Thanks to our constantly expanding standard range and our Special Serial Demand service, which offers totally bespoke designed gearboxes supplied as one-offs or in full volume production, we are able to offer a gear motor solution for almost any bulk materials handling application.

“The launch of the Industrial Drive Application Service means we are able to extend this expertise to offer our design concept of a combined power transmission package that includes the motor, inverter drive, gearbox and coupling, providing flexibility, reliability and convenience of supply to our customers.

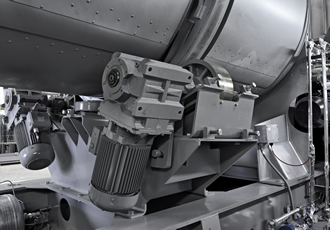

“It doesn’t matter if it is a replacement situation or a series production item for an OEM manufacturer, the key is integration and optimisation between all the components. We have even built bespoke gearboxes that incorporate the motor, gear stages and couplings into one direct fit unit.” (See images)

To augment the power transmission partnership role, Bauer Gear Motor is able to draw on the huge resources of the wider Altra Group – providing access to worldwide support and delivery of the world’s largest range of industrial clutches, brakes and couplings. The combination of expertise and product range allows Bauer to provide a solution that will not only drive, but protect and optimise the entire mechanical power transmission line.

By working closely with OEMs, Bauer engineers are able to offer the exact specification of drive train required for the application. From standard gearbox designs to those which are integrated into the machine, the design is suited specifically to the working environment and specifications of the client. Expert field engineers can assess the best solution for each individual application and offer advice on the suitability of an integrated design.

Bubolz continues: "Bulk handling equipment is often found outdoors, and in relatively inaccessible locations, so minimum maintenance and maximum reliability is essential. We exhaustively test all our modular components and engineer each product to meet the requirements of the application, with heavy duty bearings, advanced shaft seals and robust geared components, plus reinforced housings - where required.

“We also have the one of the world’s largest selections of couplings designed for misalignment compensation and vibration isolation, plus a vast range of brakes and overload protection devices available for large conveyors carrying heavy materials."

Offering a complete package also simplifies the specification process for the customer, as they only need to speak to a single contact, while reducing costs and removing the headache of specifying components which will integrate with each other. Again, the one-stop-shop approach not only delivers customer convenience and flexibility, but also a more efficient way of doing business.

Ultimately, Bauer gear motors offers a high quality, well-engineered and above all reliable and efficient solution, with responsive engineering capabilities, prototyping and delivery times as well as an extensive global sales and service network which provides local contacts and support wherever in the world the final application is located.

Similar articles

More from Bauer Gear Motor GmbH

- Keeping water treatment systems running through flood conditions 5th March 2018

- What role do motors and drives play in the water industry? 22nd June 2017

- Are motors the missing puzzle piece in drive train efficiency puzzle? 1st September 2016

- Bauer delivers efficiency for Pharmaceutical sector 10th May 2016

Write a comment

No comments