Taking The Guesswork Out Of Solar Panel Fault Finding

24th October 2011

Source:

FLIR Systems Ltd

Thermal imaging, the technology that is now widely used for a broad variety of preventative maintenance applications is proving ideal for solar panel installers. Tony Hargan of South Survey in Clitheroe sells the FLIR range of thermal imaging cameras and he confirms the falling price of the technology is proving a powerful driver. “Cost is no longer a barrier to installers using this technology. Although the advanced thermal imaging cameras offer more sophisticated functions and the ability to see faults at greater distances, an entry level model can still do the job,” Tony Hargan explains. “Thermal imaging provides a quick, easy and efficient method of pinpointing a problem cell.”

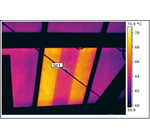

Historically installers needed to test each string laboriously to find a fault. And even if they found one to be defective the next headache was finding the cell causing the problem. With a FLIR thermal imaging camera – one of the new FLIR E-Series is ideal for the task – installers get an instant visual summary of performance.

Thermal anomalies often indicate decreased yield from the solar cell but in some cases hot spots can reach such high temperatures they present a safety risk. The thermal image can also show if the problem is the result of poor electrical connection. With a higher resolution camera it is possible to see greater detail which can reveal, for example, breakage in the protective glass layer of the cell or defective bypass diodes often caused by a thunderstorm.

There is no better method of determining the temperature profile of a solar module than with FLIR thermal imaging. It saves time, money and gives the installer vital information to ensure a job well done.

Any model in the recently introduced FLIR E-Series will allow an image of the entire installation to be captured showing cells, cables, connectors, fuse boxes and inverters so the source of the problem can be identified. And as the camera also has WiFi, images complete with their radiometric data can also be wirelessly transmitted to a iPhone or iPad for quick and easy report generation.

Thermal anomalies often indicate decreased yield from the solar cell but in some cases hot spots can reach such high temperatures they present a safety risk. The thermal image can also show if the problem is the result of poor electrical connection. With a higher resolution camera it is possible to see greater detail which can reveal, for example, breakage in the protective glass layer of the cell or defective bypass diodes often caused by a thunderstorm.

There is no better method of determining the temperature profile of a solar module than with FLIR thermal imaging. It saves time, money and gives the installer vital information to ensure a job well done.

Any model in the recently introduced FLIR E-Series will allow an image of the entire installation to be captured showing cells, cables, connectors, fuse boxes and inverters so the source of the problem can be identified. And as the camera also has WiFi, images complete with their radiometric data can also be wirelessly transmitted to a iPhone or iPad for quick and easy report generation.

Similar articles

More from FLIR Systems Ltd

- Non-contact voltage detector for electrical applications 1st June 2020

- Substation saves substantial costs from a chance thermal scan 18th September 2019

- Brickstream people counting sensor with employee filter solution 16th August 2019

- Detecting leaks from electrical circuit breakers 12th March 2019

Write a comment

No comments