Immersion Proof Breathers Prevent Damage to Enclosures and Instruments

12th February 2008

Source:

Brownell Limited

Lightweight materials used in the manufacture of electronic products often give designers the dilemma of either having to restrict the applications or to increase the strength of the enclosure walls. Heat can cause build-up of pressure within an enclosure, and without adequate venting the lightweight material could fracture.

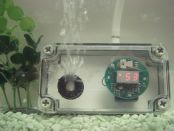

These devices allow an enclosure to “breathe” (transfer air in and out) but will withstand driving rain or even total immersion in water up to five metres. Made from robust and hard wearing plastics, the breathers can pass high flow rates of air which can result from rapid variations in pressure, caused by temperature or altitude changes.

The breathers can be screwed into a threaded boss or mounted through a hole, using a lock nut that is provided. The units can also be supplied with desiccator tubes for removal of moisture vapour.

If a controlled environment within the equipment is required, then a humidity absorber can be fitted in the rear of most immersion breathers. These absorbers are filled with beaded silica gel to prevent humidity damage and condensation.

The breathers can be screwed into a threaded boss or mounted through a hole, using a lock nut that is provided. The units can also be supplied with desiccator tubes for removal of moisture vapour.

If a controlled environment within the equipment is required, then a humidity absorber can be fitted in the rear of most immersion breathers. These absorbers are filled with beaded silica gel to prevent humidity damage and condensation.

Similar articles

More from Brownell Limited

- Hybrid Adsorbent Polymer Protects Against Humidity and Moisture 4th August 2010

- Wind turbine gearbox dryer protects lubrication oil 4th August 2010

- Purging systems removes moisture and humidity in tyres 16th December 2008

- Deluge Ultra High Flow Performance Relief Valves 27th November 2008

Write a comment

No comments