Machining

Displaying 61 - 70 of 460

New circular sawing machine significantly speeds up deliveries

Back in November 2017 it was a change in the right direction for the UK’s largest independent steel stockholder, Barrett Steel Group as it installed a KASTOvariospeed C15 automatic circular sawing machine alongside two bandsaws at its engineering division in Maghaberry, Northern Ireland. It has increased sawing productivity, reduced delivery lead-times significantly, improved accuracy and lowered cost per cut.

8th May 2018

Industry 4.0-enabled bar feeding

The first was wireless data communication from an Iemca barfeed, allowing much more information to be transmitted compared with a hard wired connection. Andrea Psotti, Iemca’s Area Sales Manager assists 1st MTA in looking after the UK sales market, and explained that the solution is unlike those offered by others in that it allows the customer to integrate the equipment more conveniently. Instead of having to be connected into a factory’s intranet to achieve wireless data flow, the Iemca barfeed and lathe communicate via the cloud.

8th May 2018

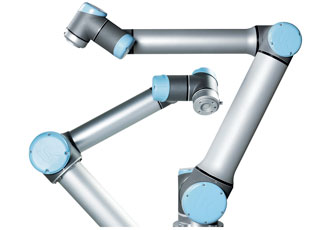

Universal robots boost profitability for machining

Multi-axis machining company, RSM is leveraging the benefits of Universal Robots supplied by RARUK Automation to load and unload its machine tools. A mix of seven UR5 and UR10 robots have helped Rousant Sherwood (RSM) maximise the productivity of its workforce by automating repetitive tasks and allowed the company to bid for contracts which would have otherwise been unprofitable.

19th April 2018

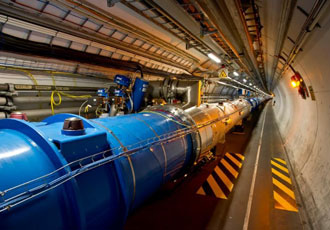

Over 140 digitisers used in machine protection systems

Over 140 digitiser cards from Spectrum Instrumentation are being used in the machine protection systems of the Large Hadron Collider (LHC) at CERN. The cards are used to check that the particle beams have been accurately deflected. Incredible precision is required for this as two high-energy particle beams travel at close to the speed of light in opposite directions in the 27km LHC accelerator ring. They are then made to collide at four locations around the ring for runs of several hours.

19th April 2018

Its essential to be safe as well as efficient

The latest safe-lock pull out protection system is becoming industry standard, HAIMER the company behind the product claim. The HAIMER Safe-Lock pull out protection system ensures safe cutting tool clamping. Special drive keys in the tool holder perfectly match the spiral shaped grooves on the cutting tool shank, thus creating frictional clamping forces and a positive locking form-fit. This effectively prevents the cutting tool from pulling out of the tool holder. Furthermore, it increases the productivity through faster permissible speeds and increased tool life.

28th March 2018

Light work made of heavyweight applications

Not long after the delivery of a Harrison Alpha 1550XS CNC lathe, during summer 2017, Fairbrother and Grimshaw saw its growing reputation spread even further, resulting in an upturn in orders, utilising the Alpha lathes versatility for taking on larger capacity mill/turn jobs. Fairbrother and Grimshaw are a Lancashire sub-contract engineering business who specialise in CNC milling, turning and boring, from their facility in the Cherry Tree area of Blackburn.

6th March 2018

Prismatic machining capabilities improved with 5-axis maching centre

Moving its prismatic machining capability forward with the purchase of its first 5-axis vertical-spindle machining centre (VMC), East Sussex-based subcontractor, Dicker Precision, is now using the German-built Spinner U620 Compact, which is supplied as a turnkey package with tooling, the initial part program and training by UK and Ireland agent, Whitehouse Machine Tools, Kenilworth.

6th March 2018

Vibratory finishing spans a multitude of applications

PDJ Vibro at MACH this year will focus on the depth of experience and expertise it offers to customers. Now in its second generation and run by managing and technical directors David and Paul Hurley respectively, the company was established in 1983 by their father John, the current chairman. With an eye to succession, passing this knowledge down to David's son Tom and Paul's two sons, James and Adam, and acclimatising them to the world of manufacturing will form an important part of the event.

6th March 2018

Low volume components on market with leading delivery times

Customers are now being offered a new method to receive small volume parts with greater expediency than normally possible, from Optimas Solutions. This service has been enabled by the installation of a Takamaz XY120 Plus CNC lathe, which can quickly mill a range of parts in quantities up to 5000 pieces.

5th March 2018