The smart plastic products that eliminate down-time

Launched back in 2016 the igus smart plastics range was the first step in the Industry 4.0 door at a time where Industry 4.0 was just a buzzword for many companies who wanted to be involved but didn’t have the product like igus. Now the range is still going strong and still developing, it is interesting to look back and see this is where Industry 4.0 started for igus.

Matthew Aldridge, Director at igus said: “It was actually 2016 at Hannover Messe where we launched the smart plastics range and it’s come on so much from then, now looking back it seems so dated but at the time we had a large amount of interest especially from customers which were paying out a lot for down-time.”

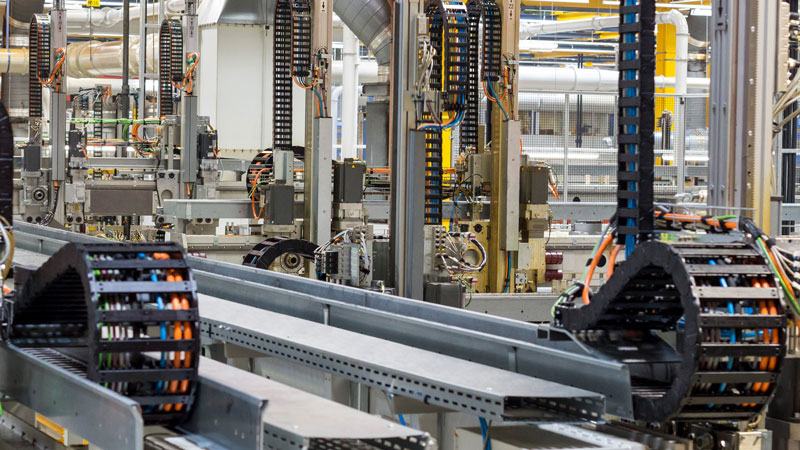

The family of smart plastics has improved with ‘isense’ sensors and monitoring modules that actually add intelligence to energy chains and moving cables. In high value industrial operations with gantry cranes and robotic systems that are moving constantly, the energy chain systems can be damaged or compromised. This is sometimes caused by general long-term wear, but alternatively it can be when a tool or work piece jams in the chain breaking with no warning. This rips cables and causes expensive unplanned stoppages while in repair.

The smart energy chain technology uses electrical and mechanical sensors to detect wear and failures, to reduce maintenance costs, eliminate unplanned down-time, maximise service life, save time on replacement and actually optimise equipment efficiency.

The isense modules collect data from energy chains to detect different failure mode indicators. The EC.M sensor detects acceleration, velocity, temperature and the number of cycles to monitor that the chains are working normally and also offer important background data for lifetime prediction.

The EC.W sensor detects wear, measures energy chain wear directly and sends a signal when a defined limit is reached. The EC.I is integrated directly in the chain link itself, and is a sensor that measures the percentage wear of the pin/bore connection without contact and therefore enables timely planning of replacement or repair.

On critical energy chain forces, such as long travel cable chain, the EC.P sensor measures push/pull forces which saves maintenance on inspecting long travel distances, but ensures that the system is stopped quickly if a foreign body enters the chain path. The EC.B sensor can detect breakage of an individual chain link that can also be caused by debris falling into the system.

You can find igus products all over the world, from bikes to medals to gantries and across a number of industries. For the automotive industry these products are crucial as down-time can cost up to £5-6,000 per minute, so for igus the priority is to save customers money by eliminating the unplanned down-time. Richard Habering, Head of Smart Plastics at igus said: “The smart plastics business unit brought together everything you could possibly need to eliminate unplanned down-time.”

There are also isense sensors designed to prevent failures of the cables themselves within energy chains. The CF.Q type checks the electrical properties of cables while moving, to predict when they will be in danger of failure due to fatigue. The CF.P ensures tensile loads on cables do not get high enough to damage the cables.

Being customisable, the smart plastic products come in various concepts for integration of the signals and data into individual infrastructure.

The simplest solution ‘isense standalone’ allow the ‘icom’ data concentrator to send signals through PLC’s to stop the machine and send alerts. Additionally with the ‘isense offline’ feature the data from the sensors can be sent to a standalone PC in the premises for further analysis or integration.

Habering added: “igus has engineered aspects of smart sensors in its products for a long time, for example with the push/pull detection system has been around for 14 years. This family of smart plastic products pulls together well established and new technology to offer high value industrial operations such as car plants a smart Industry 4.0 system of predictive maintenance for cable management.”

Similar articles

More from igus UK Limited

- From garage business to world leader: igus founders celebrate 90th birthday 22nd June 2021

- VOTW - Metal out plastic in! 10th June 2021

- igus robot works alongside agri-tech startup 18th May 2021

- Tribo-polymers increase machine service life and efficiency 10th May 2021

Write a comment

No comments