Smart Factory with IoT: smart plastics app for FANUC FIELD system

FANUC’s open industrial IoT platform, called ‘FIELD system’, evaluates data from machines and systems centrally. The system can connect production machines of all manufacturers by means of a local network topology, enabling comprehensive data analysis of the entire process line. In this infrastructure, apps from FANUC and from third-party suppliers are used. Now igus has developed a smart plastics app for the new system.

The app can be used by maintenance personnel to monitor the condition of their igus components, for example energy chains and cables, and plan all their maintenance work in good time.

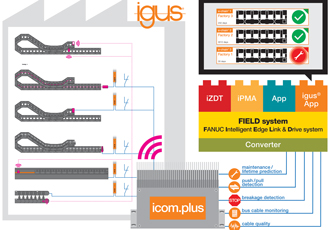

The FANUC Intelligent Edge Link & Drive system (abbreviated: FIELD) networks production machines with each other. It can work ‘on premises’ or, in future, with a Cloud link. The operating data and sensor data of the machines is gathered centrally via one server and can be viewed whenever required - efficiency is easy to monitor, production processes can be accelerated and maintenance work can be planned.

As the platform is ‘open’, any machine can be connected to the system regardless of manufacturer. Apps for the system are provided by FANUC as well as by third-party suppliers. Once the igus smart plastics app has been integrated, users can monitor the condition of their energy chains and moving cables at any time and can also plan maintenance work well in advance. In the future, the condition of slewing rings, linear and plain bearings will also be monitored with the app.

Under the name isense, igus offers a wide variety of sensors that detect the condition of igus components. They measure wear during operation and alert the user early enough to plan repair or replacement. The icom.plus communication module provides the igus data via an integrated OPC-UA server. This data is then fed into the FIELD platform by means of the FANUC Converter.

“Due to the openness of the FIELD system, the customer can now use the data and service life statements of all igus products in a protected local network environment,” explained Justin Leonard, e-chain director, igus. “The igus smart plastics app tells maintenance technicians when they should carry out the next maintenance. In this way, unscheduled machine downtime can be avoided.”

The FIELD system apps, including the igus smart plastics app, can be downloaded by the user from the FIELD system app store here, where customers can choose their preferred software solutions themselves.

Similar articles

More from igus UK Limited

- From garage business to world leader: igus founders celebrate 90th birthday 22nd June 2021

- VOTW - Metal out plastic in! 10th June 2021

- igus robot works alongside agri-tech startup 18th May 2021

- Tribo-polymers increase machine service life and efficiency 10th May 2021

Write a comment

No comments