Industry 4.0 / IIoT

Displaying 191 - 200 of 254

Nikon opens up about its strategic focus on Quality 4.0

A recent interview, Nikon's Corporate Vice President Tadashi Nakayama provided insight into the strategy of the firm's Industrial Metrology Business Unit, of which he is Deputy General Manager. In particular, he explained the company’s strategic focus on Quality 4.0, where digital, automated and connected inspection enables complete process control from design through to manufacture.

6th August 2018

Tracing production to get on the road to Industry 4.0

Implementing Industry 4.0 can seem daunting for sheet metal companies. However, Lantek has some software tools which provide the first steps, aiming to deliver practical and relevant solutions at an affordable cost, to produce an immediate impact on efficiency and customer satisfaction.

17th July 2018

BOFA brings ‘Industry 4.0’ to fume extraction at LASYS

Combining human expertise and artificial intelligence, BOFA are showcasing its latest innovations in laser fume extraction in Hall 4 Stand 4D19 at the LASYS trade show in Stuttgart, Germany from 5th-7th June. Members of BOFA’s world-renowned research and development division, along with in-house laser health and safety experts, will share a platform with their award-winning technologies that are set to bring the concept of ‘Industry 4.0’ - the fourth industrial revolution - to life.

7th June 2018

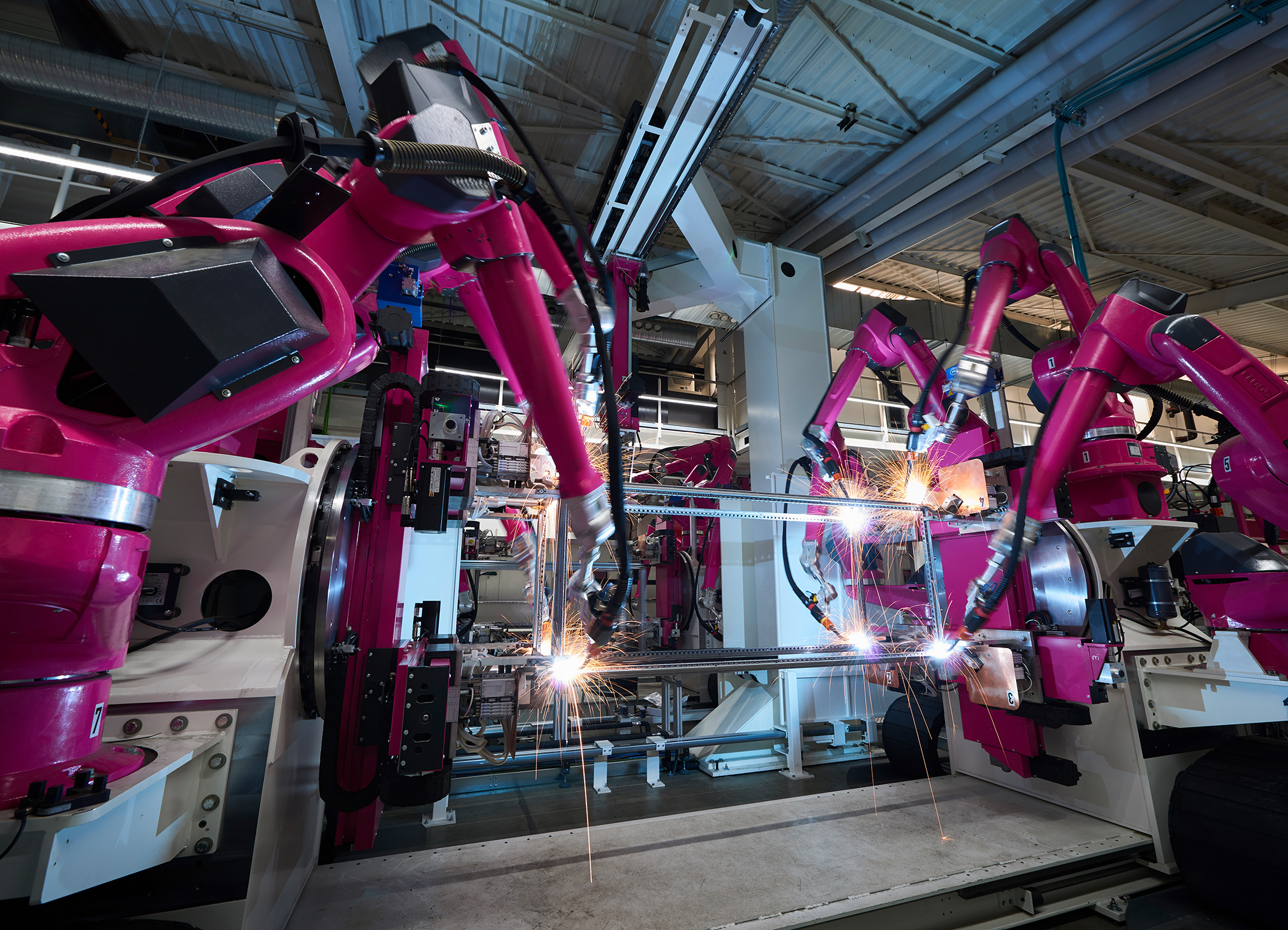

Global production as per Industry 4.0

A centre for manufacturing large enclosures is currently under construction at Rittal’s Rittershausen plant, based on Industry 4.0 principles. While work there is ongoing, Rittal is also installing high-tech production lines for its VX25 large enclosure, at a total cost of €120m. The company is gearing up its production to Industry 4.0 through consistent digitisation of processes and fully automated profiling, welding and panel manufacturing units, making the new centre a model for all Rittal production plants worldwide.

7th June 2018

How data can make money for your manufacturing business

The business landscape changes daily and with that comes new ‘buzzwords.’ You know those ones that really bug you – those where you kind of know what they mean, but they can mean lots of things and different things to different people. Well here is one for you: ‘servitisation.’ This term captures so many of the other current industry terms and buzzwords around Industry 4.0, digitisation, IoT, mobility and much more.

8th May 2018

Industry 4.0-enabled bar feeding

The first was wireless data communication from an Iemca barfeed, allowing much more information to be transmitted compared with a hard wired connection. Andrea Psotti, Iemca’s Area Sales Manager assists 1st MTA in looking after the UK sales market, and explained that the solution is unlike those offered by others in that it allows the customer to integrate the equipment more conveniently. Instead of having to be connected into a factory’s intranet to achieve wireless data flow, the Iemca barfeed and lathe communicate via the cloud.

8th May 2018

Smart manufacturing capabilities with multi-tasking smart production

Delta at Hannover Messe 2018 unveiled its integrated Smart Factory and Energy Management solutions to enable higher productivity and energy conservation through smart manufacturing. Delta’s High-Flexibility Multi-Tasking Smart Production Line features seamless integration of digital manufacturing monitoring platforms, IIoT technologies, three robot workstations and a smart conveyor to let visitors perform on-site order processing and real-time monitoring of the customised production process.

3rd May 2018

Machine predictive maintenance improves pharmaceutical productivity

Howard Forryan from HARTING here explains how valuable manufacturing production line down-time in the pharmaceutical industry can be reduced by ensuring predictive maintenance of tablet making machinery using HARTING’s MICA industrial computing platform. HARTING recently challenged postgraduate students from the Centre for Doctoral Training in Embedded Intelligence at Loughborough University to investigate practical application solutions where MICA could be applied to the benefit of UK manufacturing.

1st May 2018

In the factories of the future the focus is on humans

Digitise or be left in the dust? This is the pivotal question facing today's factories, logistics centres and power stations. Industry 4.0 is fast becoming the new standard, and that means change. IT and machinery manufacturing are converging, new business models are popping up like mushrooms, and AI is making its way into factories. And everything revolves around one central element: people power.

24th April 2018

.jpg)