Revolvo Limited

Address:

Unit 4

Yorks Park

Blowers Green Road

Dudley

West Midlands

DY2 8UL

United Kingdom

Yorks Park

Blowers Green Road

Dudley

West Midlands

DY2 8UL

United Kingdom

Revolvo Limited articles

Displaying 1 - 16 of 16

Revolvo delivers bespoke bearing solution for Thames Water

The sewage treatment works at Beckton, on the River Thames, is the largest in the UK and as such has to treat a vast volume of waste water. Part of the treatment process involves a sludge thickener tank which uses a rotating structure, known as a picket fence. When the bearing which supported the picket fence failed, Thames Water required some expert assistance from Revolvo to ensure the replacement bearing would deliver the required performance.

9th December 2014

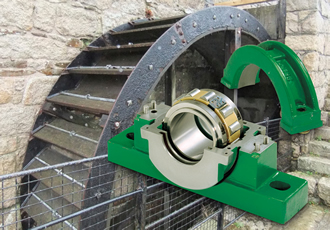

Water wheel bearings improve efficiency and reliability

For any power generation project, efficiency and reliability are two very important characteristics. So, when a 2 star Michelin restaurant in Belgium decided to refurbish its water wheel generator, it needed to source new bearings. With such close proximity to water, the new bearings would also require excellent sealing properties, which led to the installation of a Revolvo split roller bearing (SRB).

4th December 2014

Split Roller Bearing design - Making the best choice

Many businesses are focussing on reducing production costs, which includes maintenance time and lost production due to both routine and unplanned down time. By looking to make long term improvements, most production operations should certainly consider the total cost of ownership (TCO) as well as the short term benefits of reducing maintenance time where possible. In situations where large pieces of rotating equipment are in use, these savings can be achieved by introducing SRB split roller bearings.

18th September 2014

Revolvo SRB bearings accommodate misalignment without risking early failure

A recent survey by a leading global bearing manufacturer concluded that around 25% of all rolling element bearings fail prematurely, due to ineffective and inefficient seals. Sometimes bearings are specified with seals that are not fit for purpose for the demands of the application; seals can also be ineffective under conditions of shaft misalignment.

31st October 2012

Revolvo's SRB Split Roller Bearings Chosen For Refurbished Icebreaker

Revolvo’s SRB split roller bearings have been specified as part of the diesel electric propulsion system for a refurbished icebreaker that has recently been re-engined in the Ukraine. The SRB split roller bearings were specified due to their ability to be quickly changed in-situ, preventing unplanned layovers or dry docking, in the event of a bearing replacement being required whilst the vessel is in service.

3rd August 2012

Split Bearing Design & Enhanced Sealing Against Sludge Set To Radically Reduce Maintenance Costs For Treatment Plant

The split-to-the-shaft design and advanced sealing of Revolvo’s SRB bearings has resulted in their application on aerators at Wessex Water, Water Treatment Plant. The SRB split bearings allow easy maintenance, without having to remove the shafts of long horizontal rotors that agitate sewage and introduce oxygen to the treatment process. Previously a crane was required to completely remove the solid support bearings, at a cost running to thousands of pounds per day. In addition, the sealed SRB bearings are designed to withstand full submersion in sewage sludge, which can occur due to raised levels in the aerator tanks during periods of heavy rainfall.

3rd May 2012

Efficient environmental processing of waste is made possible with Revolvo’s innovative sealing solution

SRB split roller bearings are proving ideal for the latest water treatment process thanks to Revolvo’s innovative bearing sealing solution. The bearings have been specified by a leading UK manufacturer of Rotating Biological Contactors (RBC) after other bearings were shown to fail under the harsh conditions, sometimes after a matter of months. Revolvo sealed SRBs are designed to withstand full submersion in sludge, needing only routine re-greasing to last many years.

18th April 2012

REVOLVO CLAIMS MARKET LEADERSHIP IN SOUTH AFRICA FOR SPLIT ROLLER BEARINGS, THROUGH PARTNERSHIP WITH OE BEARINGS

Revolvo, the UK largest bearing manufacturer, has established itself as the market leader for split bearings in South Africa, as a result of the activities of its long standing sole distributor, OE Bearings, and from the fact that Revolvo is the only manufacturer of non ISO- sized SN SD split plummer block bearings to the South African market

21st December 2011

Bearings in large sizes up to 1.5m now available on short lead times

UK bearing manufacturer Revolvo Ltd is bucking the current trend of limited availability in large bearing sizes and offering both standard and bespoke bearings on very competitive lead times. The new service offering is already helping to extend the operational life of older plant & equipment and reduce downtime with shorter maintenance periods for other items of strategic, production critical machines.

16th December 2011

Revolvo insulated bearing technology gains market share

“Revolvo’s improved bearing insulation technique, combined with short lead times is making an impact on the world market for traction motor bearings” The move away from traditional DC traction motors to AC traction motors on locomotives and multiple unit trains, combined with the widespread use of high power AC frequency inverters to control large rotating machines, has resulted in substantially increased worldwide demand for electrically insulated bearings. Specialist UK bearing manufacturer Revolvo is currently satisfying this growing market through new business from both the premium brand volume bearing suppliers, and OEM manufacturers of railway rolling stock, electric motors and other large rotating machinery.

5th December 2011

Revolvo helps keep wind turbines turning

While there is still debate about the future for energy resources in the UK and around the rest of the world, one thing is for sure; wind turbines are becoming increasingly popular and are now a common site around the British Isles. For wind farms to have a chance of operating efficiently and meeting EU targets for renewable energy generation, it is vital that refurbishment services are available that keep wind turbines working in the harsh weather conditions they are subjected to. Thanks to its recently updated production facilities, Revolvo is able to manufacture large diameter replacement bearings to very short deadlines; reducing refurbishment lead times while increasing refurbisher’s productivity.

The issue of wind turbine refurbishment is a relatively new one; the first turbines were installed in significant numbers about ten years ago so components are only recently beginning to fail and require refurbishment. The refurbishment process usually involves gearbox rebuilds and the

24th November 2011

REVOLVO SPLIT ROLLER BEARINGS CAN REDUCE BEARING DOWNTIME BY UP TO 90 PERCENT & IMPROVE BEARING LIFE IN STEELMAKING APPLICATIONS.

The constant cost-down pressures in the steel manufacturing process mean that failures in the continuous production operation are extremely costly. Bearings of course, are fundamental components in all steelmaking production machinery. Therefore, despite the many operational challenges, bearing manufacturers are constantly under pressure to provide ever increasing levels of reliability and operating life from their products.

21st July 2011

Product Centre Updates

2024 World Battery & Energy Storage Industry Expo (WBE)

8th August 2024

China 1st and 2nd Floor, Area A, China Import and Export Fair Complex