Mitsubishi

Address:

Gothaer Straße 8

40880 Ratingen

Germany

40880 Ratingen

Germany

Mitsubishi articles

Displaying 61 - 80 of 187

Mitsubishi exhibit it's factories of the future ideas

Now factories that are populated by autonomous vehicles delivering parts and sub-assemblies across the shop floor, with robots working alongside human operators to assemble customised products are more of a common reality that are additionally scheduled automatically by live orders placed online.

23rd April 2018

Solutions for improving operations and reducing costs

The drive for increased efficiency is essential in every area of the water industry, completely integrated solutions that offer improvements to operational insight, energy usage, physical supply networks and process installations of especially high importance. At the IFAT 2018 exhibition, Mitsubishi Electric will be presenting its approach to meeting these needs, which has been developed based on an understanding of industry requirements from water automation projects from around the world.

16th April 2018

Data exchange between electrical wiring and control software

The AutomationML interface within iQ Work has been implemented by Mitsubishi Electric, which is the integrated software suite for programming Mitsubishi Electric automation products. AutomationML represents an important step-change in the way complex equipment is designed, installed and maintained. Designers, integrators and end users will all benefit from a streamlined approach to system implementation that will drive down costs and shorten time to market.

28th February 2018

Are we over-complicating a simple idea?

With an increasing modularity in PLC components, it means that principle life has been getting easier for systems integrators of late, with the ability to implement complete automation systems on a single backplane. However, with a host of new PLC modules making it feasible to implement full control of a complete production line without ever leaving the PLC rack, are we at risk of over-complicating a simple idea? Barry Weller of Mitsubishi Electric argues that, actually, this is all for the better.

29th January 2018

Delicious! SCM solution received 2017 Food Processing Award

Having won the Continuous Improvement category at the 2017 Food Processing Awards, Mitsubishi Electric has gained further recognition for the innovative Smart Condition Monitoring (SCM) solution. Part of the Appetite for Engineering conference, the annual Food Processing Awards are designed to recognise and reward engineering innovation in the food and beverage sector.

8th January 2018

Mitsubishi brought it all to the 2017 SPS Drives show

Mitsubishi Electric had a very busy show at this year’s SPS Drives showcasing a range of new products and solutions from collaborative robots, to modular linear transfer systems and smart carriages, especially as the company was like many, concentrating on the big focus of the show Industry 4.0 and digitalisation. Anna Flockett, Engineering Specifier editor attended the Mitsubishi press breakfast at the SPS show, where the first innovation that was easily noticed was the demonstration of production in an Industry 4.0 environment which included a new collaborative robot, working together with an operator without safety barriers.

11th December 2017

Automation platform supports the manufacturing digital transformation

At this year’s SPS Drives show in Nuremberg, Mitsubishi Electric was highlighting the benefits of the PLC as a platform for automation, with a complete set of dedicated CPU modules for the MELSEC iQ-R Series PLC. A CNC CPU module and a robot control CPU now complement the existing options for analogue and digital I/O, motion, positioning, process control, safety and networking, delivering a solution that integrates the full suite of control and automation processes onto one common platform.

8th December 2017

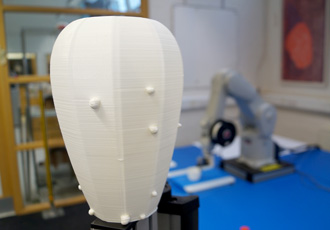

Six-axis robot turns 3D printing into an art form

There is a current project underway at the Centre for Fine Print Research (CFPR) which is looking at 3D printing from a totally different angle - where the emphasis is placed on meaningful expression, rather than the accurate reproduction of digital data, and at the centre of the project lies a flexible Mitsubishi Electric MELFA RV-7FLM articulated arm industrial robot.

27th November 2017

Packaging machines optimised for ease of integration

There are challenges facing today’s packaged goods manufacturers to reduce costs per package unit, on lines that need to be flexible and ready for the introduction of the latest packaging innovations. However, at the same time, production lines need to be more tightly integrated, with improved monitoring at a local IT level for both production and performance data.

30th October 2017

Profit and production in automation solutions stole the show at PPMA

The PPMA show this year was very successful for Mitsubishi Electric, as the company demonstrated the benefits of advanced automation systems and solutions for packaging machinery. Taking centre stage visually was a Proseal GT0 automatic in-line tray sealing machine, equipped with high-speed heat sealing technology, touch screen HMIs, PLCs, drives, servo control and robot handling.

16th October 2017

New concept in robotics for predictive maintenance

EMO 2017 saw Mitsubishi demonstrating innovative predictive maintenance possibilities for robots that can reduce operational costs, increase asset productivity and improve process efficiency. The cloud-based solution is based on the AI platform within IBM Watson, which enables the smart analysis of operational data to highlight maintenance requirements.

2nd October 2017

Addressing the need for fast control of machine tools

How important is the need for fast, precise and affordable control of machine tools for complex machining applications with a new range of CNC systems? Mitsubishi Electric is addressing this with the the M800 and M80 controllers, which offer superior functionality and intuitive usability. Enabling users to boost productivity in application areas such as automotive manufacturing, medical component machining and other sectors requiring a combination of high throughput and reliability.

27th September 2017

Human orientated machine operation demo at EMO 2017

Mitsubishi Electric is providing a glimpse of the future with human orientated monitoring and training for CNC machines at EMO 2017, using smart devices offering direct integration with machine control systems. Developed as a pilot project with the Fraunhofer Institute for Production Technology IPT, the demonstration on the Mitsubishi Electric stand shows how smart tablets and smart glasses can be used as the user-interface with a CNC controller on a 5-axis CNC machine to support the user on a new digital level.

26th September 2017

Solutions for the digital transformation of production

In an increasingly competitive manufacturing environment, businesses need flexibility, improved productivity, and the capability to make gains in efficiency and reductions in down-time. Mitsubishi Electric is showing how these requirements can be met with a focus on connected production systems, intelligent control systems, Edge Computing solutions and smart services at EMO 2017.

22nd September 2017

Automation platforms deliver productivity in food production

For food and beverage manufacturers there are many benefits in rationalising their automation vendors. Using a single source of supply for automation components can play a big role in improving flexibility and reducing downtime. However, as Jeremy Shinton, Mitsubishi Electric explained, an automation system can be much more than just the sum of its parts.

21st September 2017

Delivering solutions for digital transformation at EMO 2017

The Mitsubishi Electric stand at this year’s EMO Hannover will provide visitors with the opportunity and experience to benefit from ongoing digitalisation at a manufacturing level. The theme ‘e-F@ctory – pushing business further’ covers a wide range of technologies aligned to current challenges in the machine building sector.

30th August 2017