Tyre plant saves €119,000 a year

Molded-Oil rolling bearings from NSK have once again proven their suitability for operating in harsh environmental conditions by helping a tyre manufacturing plant in Europe achieve annual cost savings of over €118,000. Having replaced conventional bearing units in a rubber cutting machine with NSK Molded-Oil bearings, which are permanently lubricated with an oil-impregnated polymer material, the facility is witnessing a four-fold extension in bearing service life.By changing to NSK´s Molded-Oil rolling bearings in a rubber cutting machine, a tyre manufacturer is saving over €119,000 a year

Water spray generated by the tyre cutting process is known to shorten the service life of standard ball bearings deployed in such applications. However, at this particular plant, the problem was exacerbated by inadequate protection at the bearing locations. As a result, the maintenance team was faced with replacing the bearings prematurely, typically twice a year. This was in addition to an average of two unscheduled stoppages per annum due to catastrophic bearing failures and line stops.

Within the framework of its proven AIP Added Value Programme, engineers from NSK visited the plant to see the application first hand before analysing the bearings at one of its technology centres. There, it was confirmed that the principal cause of bearing failure was the ingress of water from the rubber cutting process. As a consequence, NSK determined that the optimum solution would be the adoption of stainless steel mounted units with Molded-Oil inserts.

In ball bearings featuring Molded-Oil technology, the penetration of water and other contaminants is prevented by a resin containing a supply of lubricant that is distributed in small, continuous quantities on to the raceway. In comparison with resins used by manufacturers of competitor bearings, the ratio of lubricant present in NSK´s Molded-Oil bearings is significantly higher (often over 50% more), thus extending service life.

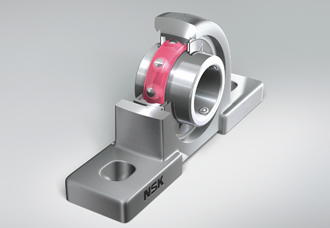

The mounted Molded-Oil units now being deployed at the tyre manufacturing plant feature a housing made from a one-piece austenitic stainless steel casting. The bearing rings, balls and raceways are also made of stainless steel, while further corrosion resistance for both the housing and bearing interior is assured by the Molded-Oil resin coating.

NSK Molded-Oil bearings are suitable for applications where the ingress of water and contaminants must be prevented

Since putting NSK´s recommendation into practice, the tyre manufacturer has witnessed four times greater service life from each bearing unit; the bearings are now replaced only once a year instead of the three month cycle endured previously. When assessing lost production time and the cost of replacement bearings, the annual net savings from using Molded-Oil pillow block type bearings with stainless steel housings was calculated at €119,000 per year.

Similar articles

More from NSK UK Ltd

- Pizza plant saves over €15,000 after switching bearings 18th March 2019

- Triple-lip sealed bearing units save €13,000 12th September 2018

- Optimise bearings to avoid production downtime 6th September 2018

- Condition monitoring for bearings improves grinding process 24th August 2018

Write a comment

No comments