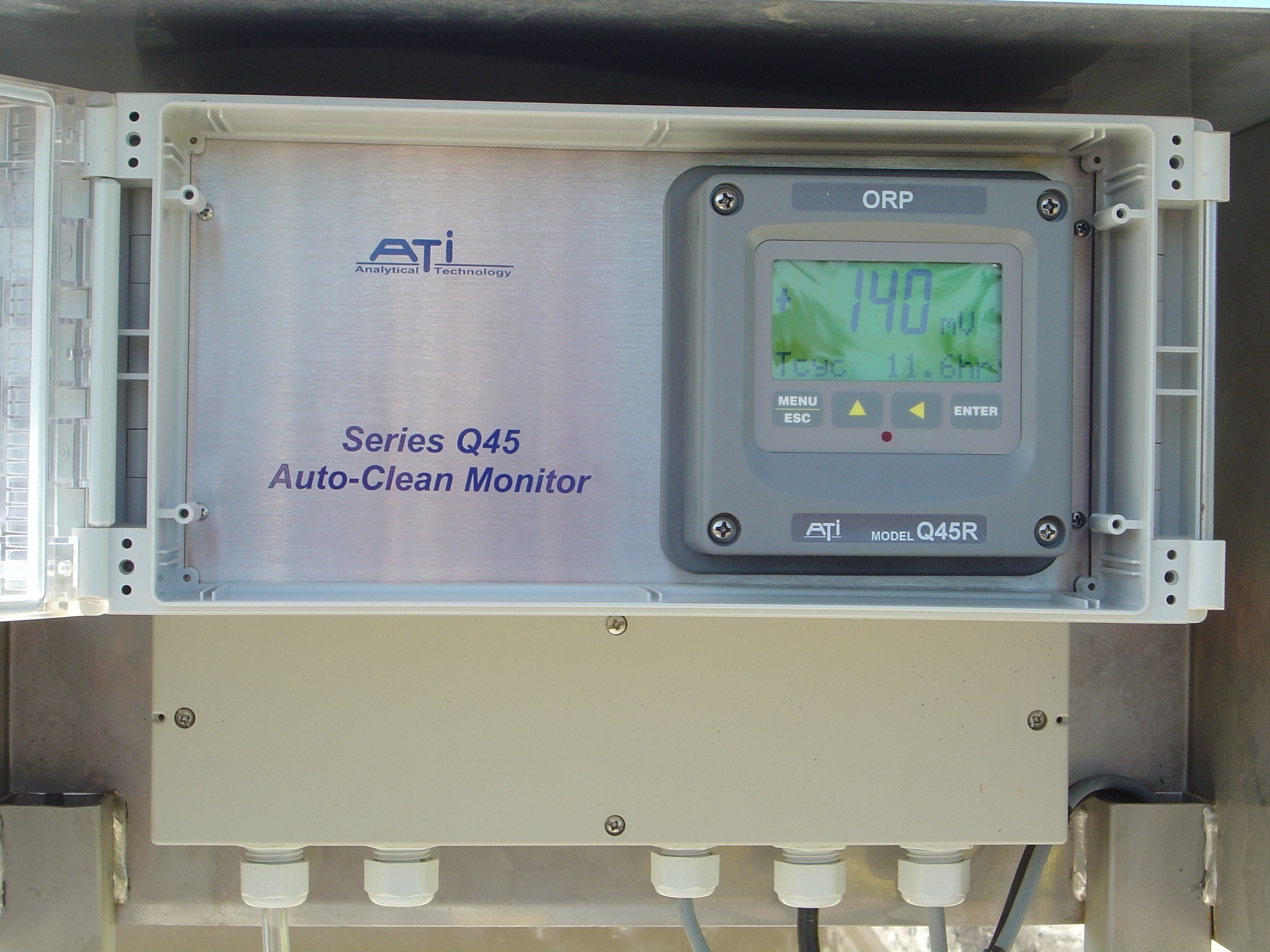

The Royal Mint Improves pH Control and Compliance in Water Effluents with ATi’s Q45/72 pH/ORP Monitor

Analytical Technology Inc. announces that the Royal Mint has selected its Q45/72 pH/ORP monitor to improve the quality of its effluents and to better comply with Environment Agency regulations. The versatile Q45/72 system is designed for use in industrial and municipal applications and contains sensors specifically engineered to function normally in applications where conventional sensors typically fail.

Effluents originating from metals manufacturing plants in the UK are strictly controlled by Integrated Pollution Prevention and Control (IPPC) guidelines set by the Environment Agency. These regulations aim to eliminate potentially toxic substances found in trade effluent by setting parameters including the maximum volume of the discharge permitted, the chemical oxygen demand, the pH value, the temperature and the suspended solids concentration. Traditionally the Royal Mint has used precipitation plants with hydroxide dosing to adjust the pH value of its effluents. However, due to the nature of the metals being manufactured, the effluent in the pH sensor tank has an extremely high solid content, meaning that pH probes and electrodes require cleaning a minimum of once a day and as a result of this sensor fouling, the pH readings can be less reliable.

The differential pH/ORP sensors in ATi’s Q45/72 monitor consist of a sealed reference system with a second glass pH electrode as the reference element in the sensors. The glass reference system protects the sensor from chemical poisons such as sulphide, cyanide, chlorine and bisuphite, which can destroy conventional pH sensors. Sensor electrodes can be user-specified to ensure measurement reliability and maximum sensor lifetime. The type of glass used in the pH electrodes can be selected for optimal performance, and the metal electrode for ORP measurement can be platinum or gold, depending on the chemical makeup of the process solution.

The Royal Mint worked with independent consultancy company Integrated Effluent Solutions to review their existing pH systems and to improve the pH control and efficiency of the effluent plants In order to eliminate the need for everyday sensor cleaning and operator input, and to improve efficiency in a cost-effective way, IES specified the ATi Q45/72 monitor for the Royal Mint application. ATi’s system has a unique Auto-Clean option, which is designed to extend cleaning intervals on pH and ORP sensors in applications with high levels of solids contamination. The ATi Auto-Clean Q45/72 system uses an integral high pressure air supply to automatically remove contaminants from the face of the sensor.

Graham Hartry, Environmental Manager (Blank Processing) at the Royal Mint, comments: “Ensuring compliance with environmental regulations is extremely important to the Royal Mint, and we take our commitment to controlling our effluents seriously. When looking into improving our pH systems, we found that most sensors required cleaning either manually or by installing a separate cleaning system. By supplying the ATi Q45/72 Auto-Clean monitor, IES has provided us with a stand-alone solution to pH control challenges, enabling us to reduce operator intervention at the same time as improving effluent control.”

Similar articles

More from Analytical Technology Inc

- Roundtable Meeting Highlights Need for Improved Maintenance of Dissolved Oxygen Sensors for Increased Efficiency and Accuracy for Water Treatment Plants 12th February 2013

- Research into Gas Detection in the Workplace Reveals Lack of Confidence in Gas-Monitoring Set-ups 9th October 2012

- Analytical Technology Demonstrates Commitment to Protecting the Environment 4th September 2012

- Analytical Technology Continues Water Monitoring Success by Securing Prestigious Framework Agreement with Wessex Water 25th November 2011

Write a comment

No comments