Lafert Motors Helping To Reduce Building Carbon Footprints

13th February 2008

Source:

Lafert Electric Motors Ltd

The latest L2 Building Regulations introduced by the Office of the Deputy Prime Minister (ODPM) demand that every new building – domestic and commercial – must be pressure tested to check air leakage. This is part of the UK Government’s drive to reduce the carbon footprint of all new builds in line with its Kyoto Protocol commitments.

Initially these Building Regulations were introduced in April 2002 but applied only to commercial properties over 1000 m2. Since April 2006 they have applied to all new builds, domestic as well as commercial with some easement up until October 2007 from when complete compliance was required. Buildings must meet appropriate air leakage standards in order to obtain completion certificates.

CPS of Ipswich provides a service to construction companies that verifies their buildings compliance with these new energy saving requirements. The significance of compliance is illustrated in that if air leakage is cut by half heating/cooling costs are cut by as much as 40% whereas a doubling of insulation only achieves a 10% saving.

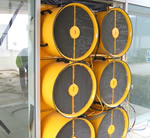

The very nature of the testing service offered by CPS demands that its building pressurising equipment must be readily transportable. This means its fans, which develop the pressure required (50 Pascals) inside the buildings, must have the power demanded yet be light enough to be easy to move and install on site.

After approaching a number of motor companies, James Mitchell, managing director of CPS opted for the ‘Progressive Motors’ from Lafert Electric Motors. “Of course the motors had to be ‘fit for purpose’,” he commented “but Lafert seemed keener to understand our requirement in order to provide the right solution – which is Lafert’s strength.” The motor used by CPS is 0.75kW 2 pole 71 frame machine.

Lafert’s Progressive motors are designed to give engineers more power for weight/size than conventional comparable IEC frame size machines. The motors are ideal for manufacturers that have restricted space envelopes, weight restrictions or simply want to be more competitive.

As an example, the highest output from a standard IEC 132 frame 2 pole motor is 7.5kW; a comparable Lafert Progressive motor can double this (15kW). Similarly, a 160 frame 4 pole Lafert progressive motor can produce 22kW whilst a standard IEC machine offers 15kW.

They are available as 2, 4 and 6 pole units. Two pole motors are available in frame sizes from 63 to 180 with powers up to 30kW; 4 pole units 63 to 250 with ratings up to 75kW and 6 pole machines 100 to 132 and 7.5kW.

The increased output from the motors is made possible by extending the internal lamination pack and building in more active material. Some of the motors utilise the class F temperature rise available from class F insulation. The multi-voltage input of 380-420V 50Hz/440-480V 60Hz is unaffected and still available.

In addition to providing on-site building pressurisation and leakage measurement, CPS offers a service that covers every stage of building construction. It includes consultation and advice from the drawing stage, site visits at key stages of construction and final inspection before tests are carried out. The company even has its own material testing facilities to determine individual product air leakage characteristics.

CPS of Ipswich provides a service to construction companies that verifies their buildings compliance with these new energy saving requirements. The significance of compliance is illustrated in that if air leakage is cut by half heating/cooling costs are cut by as much as 40% whereas a doubling of insulation only achieves a 10% saving.

The very nature of the testing service offered by CPS demands that its building pressurising equipment must be readily transportable. This means its fans, which develop the pressure required (50 Pascals) inside the buildings, must have the power demanded yet be light enough to be easy to move and install on site.

After approaching a number of motor companies, James Mitchell, managing director of CPS opted for the ‘Progressive Motors’ from Lafert Electric Motors. “Of course the motors had to be ‘fit for purpose’,” he commented “but Lafert seemed keener to understand our requirement in order to provide the right solution – which is Lafert’s strength.” The motor used by CPS is 0.75kW 2 pole 71 frame machine.

Lafert’s Progressive motors are designed to give engineers more power for weight/size than conventional comparable IEC frame size machines. The motors are ideal for manufacturers that have restricted space envelopes, weight restrictions or simply want to be more competitive.

As an example, the highest output from a standard IEC 132 frame 2 pole motor is 7.5kW; a comparable Lafert Progressive motor can double this (15kW). Similarly, a 160 frame 4 pole Lafert progressive motor can produce 22kW whilst a standard IEC machine offers 15kW.

They are available as 2, 4 and 6 pole units. Two pole motors are available in frame sizes from 63 to 180 with powers up to 30kW; 4 pole units 63 to 250 with ratings up to 75kW and 6 pole machines 100 to 132 and 7.5kW.

The increased output from the motors is made possible by extending the internal lamination pack and building in more active material. Some of the motors utilise the class F temperature rise available from class F insulation. The multi-voltage input of 380-420V 50Hz/440-480V 60Hz is unaffected and still available.

In addition to providing on-site building pressurisation and leakage measurement, CPS offers a service that covers every stage of building construction. It includes consultation and advice from the drawing stage, site visits at key stages of construction and final inspection before tests are carried out. The company even has its own material testing facilities to determine individual product air leakage characteristics.

Similar articles

More from Lafert Electric Motors Ltd

- Meeting the hygiene requirements of the food and beverage industry 5th August 2016

- Compliant motor solutions for your applications 1st March 2016

- Ex-Stock Deliveries for Lafert HPS High Efficiency PM Motors 25th September 2012

- Custom Motor Solution Brings 20 Years Of Reliability 10th October 2008

Write a comment

No comments