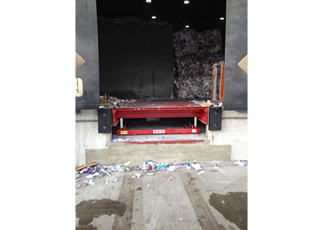

Bespoke dock leveller keeps waste paper bails flowing smoothly to Chinese recyclers

sara LBS has helped one of the UK’s leading recycling and waste management companies to replace a hardworking loading bay dock leveller at its busy East London plant. By completing all the installation work in a single day there was minimal disruption to the plant’s workflow.

Bywaters has been serving London and the South East of England since 1952, providing a range of tailor-made recycling and waste management services to all types of organisations. Its state of the art transfer facility at Bow is designed to constantly set new recycling and waste management standards for the UK and the world, so there is always a drive to innovate and develop new services.

The original dock leveller was a sara LBS unit, installed when the site was opened 10 years ago. Like all equipment on site it, had been maintained to a high standard and was still working well despite the harsh operating environment and long hours of use. However, Bywaters understood that as a vital element in its everyday operations it was sensible to replace while it was still efficient and reliable.

sara LBS supplies, installs and maintains loading bay equipment for manufacturing, warehousing and distribution organisations of all kinds. It can provide single products such as dock levellers, scissor lifts, dock shelters, ramps and powered doors, or total packages that include design, installation and ongoing maintenance services for complete loading docks.

sara LBS and Bywaters worked together on the new leveller, with both companies contributing to the planning and actual installation. The first step was to assess the existing facilities and decide the best design and equipment for the new system, which is expected to operate two or three shifts a day, seven days a week for 10-12 years.

The original levellers were top hung, cast into letter box tail lift pits and designed to lift a range of materials. In recent years, as Bywaters’ plant and services have evolved, the levellers have been used exclusively for paper bails. The bails weigh two tonnes each and are lifted two at a time into shipping containers, which when full are transported to the nearby docks and shipped to China for recycling.

The design team decided that they did not need a tail lift facility, such had been fitted originally, but required a heavy duty leveller and specified that this should have a hydraulically driven lip that could swing out to contact the bed of the shipping container into which the bails are loaded.

The solution sara LBS proposed was a leveller from its TS range, which would be able to lift the bails and/or shipping containers as required. It is electro-hydraulically operated and based on an all-steel design that uses a suspended sub-frame supported within a rebate at the top of the pit. The TS dock leveller incorporates a fully adjustable, hydraulically operated telescopic lip as standard, giving the flexibility to service a wide range of vehicle types.

The TS is designed to be highly customisable and easily integrated with other sara LBS loading bay equipment. The leveller built for Bywaters was fitted with a 10/12 mm heavy duty platform and was designed to be about 10 percent narrower than the standard 2m width to better fit the space available in the existing pits. Thinking 10 years ahead, a concrete base was cast for the leveller to sit on, which will make future replacement a lot easier.

The TS leveller complies with international industry standard BS EN 1398. Additionally the load platform is manufactured from 8mm durbar non-skid steel plate as standard and the design includes two heavy duty steel cross traffic legs for stability when in the parked position at dock level. It has side tilt compensation of up to 150mm, which facilitates easy transferral of pallets from the leveller into their shipping containers and safe entry into unevenly parked vehicles.

With the leveller designed and built to the exact specification for the job, sara LBS delivered it to site and then, working with Bywaters’ own in-house engineers, completed the installation and commissioning in under a day. Bywaters was insistent on minimal disruption to normal production operations, because the container ships that transport the waste paper bails to China run on very tight loading schedules, docking for only the minimum period and preferring to leave on time rather than wait for late loads.

Similar articles

More from Sara Loading Bay Specialists Ltd

- Fast tracking loading bay fit-outs 10th May 2019

- Keeping your cool when the heat is on 12th February 2019

- Insulated roller shutter doors with improved performance 29th January 2019

- High speed doors keep winter at bay 13th November 2018

Write a comment

No comments