Ultra-slim thin section bearings for innovative laser terminals

New kinds of laser communication systems in aeronautical applications make it possible to transmit enormous quantities of data. For example, aerial photographs can now be transmitted to a ground station during flight – over such long distances, even space seems almost within reach.

By Julia Schneiders, Marketing & Sales Precision Bearings, Rodriguez in Eschweiler, Germany

It sounds like science fiction, but it has been reality for a long time: The systems in question have been developed to market readiness by the German company ViaLight Communications. In the company's successful MLT-20 laser terminal, a thin section bearing from Kaydon is responsible for the most exacting precision in data transmission.

ViaLight Communications GmbH is a spin-off enterprise from the Deutsches Zentrum für Luft- und Raumfahrt (DLR), [German Aerospace Center] and concerns itself with Free-Space Optical Communications (FSO). In specific terms, the team consisting of scientists develops and implements laser communication systems for transmitting large volumes of data in aeronautical applications.

"The background is that modern camera systems for aerial photography generate a lot of data," said Dr Markus Knapek, CEO of ViaLight.

If the images that have been captured are to be provided for analysis rapidly and transmitted to a ground station even while the aircraft is still in the air, the communication link often constitutes the bottleneck: "Until now, this data was transmitted mainly via wireless solutions, but these are subject to physical and regulatory constraints. These have the effect of seriously limiting transmission rates in practical operations."

In contrast, the laser data transmission systems from ViaLight are capable of significantly higher data rates. They are also less bulky and more powerful than conventional wireless devices, and also very difficult to intercept. Logically, the technology offered by ViaLight is of interest mainly for reconnaissance and defence, telecommunication and science applications – but these solutions also present opportunities for the film industry as well.

"Until recently, our efforts were invested mainly in proving the concept itself with our products," added Knapek. "But now our laser terminals are ready for market and we have begun series production."

Reliable components for an innovative laser terminal

For this new marketing phase, in 2014 ViaLight began looking high-quality components for its Micro Laser Communication Terminal, the ‘MLT-20’. This is a solution for small airborne craft such as drones or helicopters.

The highly compact system weighs just five to eight kilogrammes and is equipped with an innovative alignment mechanism, it requires little energy and can dissipate heat efficiently. The terminal is optimised for the dynamic behaviour of agile, high-vibration aerial platforms; it transmits data at rates up to 10 Gbps over distances up to 50 km.

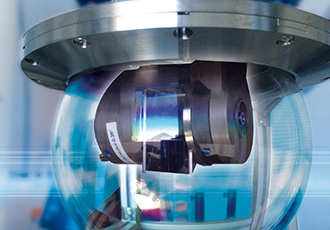

The external mounting profile of the MLT-20 is reduced to a minimum and is correspondingly small. The entire sensor system and control unit is accommodated in a small, integral housing. The laser communication system consists of two units. The coarse alignment unit is located on the outside of the fuselage tank; it is protected by a small glass dome no larger than a coffee cup.

This is complemented by a fine alignment unit inside the tank: For this unit, a special sensor system and movable mirror compensate for the vibration of the aircraft and ensure that the alignment of the laser beam remains stable.

Exacting requirements for the ball bearings

The laser terminal must be able to track the ground station flexibly in order to maintain the data link at all times. Therefore, the coarse alignment unit of the MLT-20 is based on a two-axis tilt mechanism with direct drives. To ensure optimum transmission of the laser beams, the alignment mechanism must operate with an extraordinarily high degree of precision. This in turn can only be achieved by eliminating non-linear friction within the system as completely as possible.

"For operation in the azimuth axis of the coarse alignment unit, we therefore wanted to find ball bearings which were able to satisfy these strict requirements," explained Knapek. "The most important characteristics for us were extreme precision and speed, low friction, small dimensions and low weight."

Kaydon's German distributor Rodriguez GmbH assisted as a top-quality system supplier of high-performance drive components.. Because included among the components they offer are the Ultra-Slim thin section bearings from Kaydon, which satisfy the requirements of ViaLight in every detail. These bearings from the manufacturer Kaydon are unique in that each series is based on a single, small cross-section which remains constant even as the bore diameter increases.

Thus they allow compact, lightweight design of bearings while still permitting cables or shafts to pass through the bore. The extremely thin bearings deliver outstanding performance with diameters from 35 to 200 mm and a particularly small cross-section of just 2.5 to 3mm. The laser terminals from ViaLight make use of stainless steel Ultra-Slim thin section bearings with dimensions from 60x66x2.5mm.

"Stainless steel is a good choice when extreme precision and corrosion resistance are both required, as in the case of ViaLight", explained Ulrich Schroth, Division Manager for Value Added Products at Rodriguez. "Typical application areas for thin section bearings are space flight, the semiconductor industry and medical technology."

"Because of these special bearings we have been able to improve the precision of our coarse alignment unit significantly," explained Knapek. "This has been confirmed in demanding practical tests such as the most recent ones in the Canary Islands, during which laser beams were transmitted over a long distance of 145 km.”

The project was conducted in cooperation with the European Space Agency (ESA): A communication link between the MLT-20 laser terminal and a mobile ground station operated by the DLR was set up on mountain summits on Tenerife and Las Palmas respectively. The distance of 145km was not chosen at random: It is roughly equal to the distance a laser beam must travel to reach the Earth from space.

Similar articles

More from Kaydon Bearings

- Ultra-slim thin section bearings for innovative laser terminals 1st July 2019

- Robotics counts on thin-section bearings 10th April 2019

-(1)ed.jpg)

Write a comment

No comments