Stellar vice guarantees precision machining

Committed to making bikes and cycling cooler than ever, an engineering company has added a cutting edge work holding vice from WDS Component Parts to its high tech manufacturing operation in Lincoln. Twenty years ago bikes were only for people who could not pass their driving test, but since then the likes of Chris Hoy, Dave Brailsford and Victoria Pendleton have so completely changed perceptions that even Boris Johnson cannot tarnish their image.

Behind the famous Olympian and celebrity cyclists there is now a sophisticated UK manufacturing industry making a full spectrum of components and accessories, including high performance and innovative designs.

One such company is Superstar Components. This was started in 2006 with a single aim: cut out the middleman and sell high quality parts direct to customers at sensible prices. From the humblest of beginnings it now makes a wide range of products for both mountain and road bikes, combining CNC machining, laser precision and traditional craft skills. All of its parts are designed to be durable, serviceable, eco-friendly - and cool beyond compare.

It was always part of the Superstar dream to manufacture parts in the UK. In fact it now has design, prototyping, programming and manufacturing all under one roof. It has invested in the best equipment and the best people and uses aerospace quality materials. For instance, it commissioned a custom designed wheel building machine that uses direct drive torque motors, a computer and three lasers so that every single wheel is built to 0.2mm accuracy, with zero spoke twist and even spoke tension.

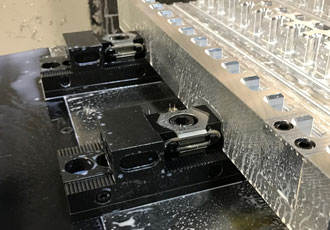

Superstar has also installed high performance CNC machining centres to form the core of its manufacturing operations. As customer demand has grown, these machines have had to work harder and more efficiently. To this end Superstar has recently sourced a new working holding vice from WDS that allows series machining of multiple bicycle components and accessories.

WDS is a leading European manufacturer and a global supplier of standard parts, machine accessories and workholding components for the design, engineering and manufacturing markets. It supplied Superstar with a new type of vice made by Finnish company OK Vise. This is mounted on a castellated rail so that it can quickly be positioned at a set point, accurately and securely.

Like Superstar, OK Vise was founded on a desire to redefine user expectations through performance and quality. In the early 1980s, Finnish entrepreneur and inventor Olli Kytölä (‘OK’) bought his first CNC machining centres, but was frustrated with the large size and small clamping force of the machines’ vices. In a light bulb moment he conceived of a low-profile screw anchor type alternative that would meet his every work-holding need.

With OK Vise products now available around the world, a new multi-rail mounting system has been launched. This allows multiple workpieces to be clamped simultaneously for serial machining, and can also be used to secure very large workpieces in place.

The basic concept of the system is a rail with teeth, or constellations, precision machined into the top surface and hardened. End stops can be securely mounted onto the rail, the accuracy of their position being ensured by the teeth. The end stops are used to position vices so that a number of workholding stations can be defined. Alternatively the rails can be configured to hold large or unusually shaped workpieces.

Neil Wilkinson, Director at Superstar Components said: “The vice has given us the ability to hold parts outside of our normal working envelope. Instead of a general jobshop multipurpose approach, we have bespoke machines designed to hold certain parts. The vice allows us to easily and quickly convert one of our machines to hold large plates for making tooling rather than having to subcontract the job.”

Chris Putman, Sales Director for WDS explains that the OK Vise multi-rail system is available in a number of variations and is compatible with workholding tables, towers, hydraulic clamps and other systems, so offers a very flexible and highly efficient way of holding workpieces for machining.

“Workholding is a vital part of precision engineering,” he said. “If the workpiece isn’t held securely in exactly the right position, you are never going get an accurately produced part no matter how high tech the machining equipment or how skilled the operator. WDS has helped develop work holding solutions for aerospace, medical engineering, micro machining and many other industries. Modern bike component manufacture is as high tech as any of them.”

Similar articles

More from WDS Component Parts Ltd

- Quick release pins now available with D-ring 8th October 2019

- Hydraulic shock absorbers make for smooth operation 18th September 2019

- Technical support eases difficulties during development 20th August 2019

- Easing difficulties during development of new motorbike trailer 15th July 2019

-(1)ed.jpg)

Write a comment

No comments