New designs extend range of workholding clamps

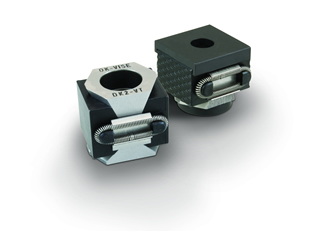

WDS has extended its OK VISE range of workholding clamps to include single and double edge clamps with a variety of jaw options, including smooth, tapped, serrated and smooth types, self-adjusting jaws and ball bearing grippers.

These low profile clamps offer high clamping forces and the potential for three directional machining, so are highly efficient in use. They are widely used in industries such as metalworking, plastics, aerospace, and electronics.

One key feature of the OK-VISE low-profile clamp design is its cross-wedge structure in both the horizontal and vertical planes, which means that the clamp is locked firmly in every direction as it is tightened down, thus preventing sliding.

They come in two basic designs. The first option is based on a single-wedge design which will steadily increase the gripping force with which it holds the workpiece. The second option uses a double-wedge construction that creates a pull-down action that ensures the workpiece is firmly seated in the clamp.

Both the wedge and the jaws are made of tool steel and are through-hardened. Fastening the clamps involves simply tightening a single bolt, an operation which ensures quick yet accurate set up times.

They are designed to fit between the workpieces and take up very little space on the fastening base. Small in size yet exerting a clamping force of up to 150kN, they can be used on both single machine tools and large flexible manufacturing centres.

Standard models come with a hardness of 48-52 HRC and serrated jaws. Smooth jaws and other options are now also available, along with a line of machinable jaw models for workpieces of irregular shape and special models for castings and wire EDM applications. WDS can supply all versions.

OK-VISE low-profile clamps are designed to fit into grid pattern bases, T-slot tables, serrated rails, and many other types of machining platforms and plates. They are suitable for three-directional machining, five-axis machining, and many other efficient modern machining methods.

In use, the low-profile of the OK VISE clamps means they do not require as much space as traditional clamps. This leaves more of the machining area for workpieces, thus reducing the need for operator intervention and tool changes, which can lead to reduced machining downtime and longer production cycles.

Thanks to their small size, these light-weight clamps are easy to install, while moving them from one application or machine to another is virtually effortless.

Similar articles

More from WDS Component Parts Ltd

- Quick release pins now available with D-ring 8th October 2019

- Hydraulic shock absorbers make for smooth operation 18th September 2019

- Technical support eases difficulties during development 20th August 2019

- Easing difficulties during development of new motorbike trailer 15th July 2019

-(1)ed.jpg)

Write a comment

No comments