Welsh die caster earns LED lighting contract

A large order for bespoke aluminium enclosures is currently being delivered by Mark Aluminium Die Casting (MADC), based in North Wales, for a leading LED lighting company. The order follows on from MADC’s recent expansion into the aluminium cases market due to demand from companies choosing to re-shore their supply contracts and avoid the long lead times and large minimum order quantities associated with overseas supply.

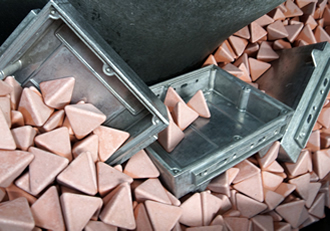

The LED lighting company required six different sizes of enclosure; each variant incorporating the fins required for it to perform as a heat sink, plus, bespoke cable entries, cable gland location and retention features, and precision mounting points - used to speed up the time taken to install other components.

An Aluminium die cast construction was chosen for its inherent ability to withstand outdoor conditions, its relative lightness - compared to other metals and general all round anti-corrosion and robustness qualities when compared to press and painted mild steel.

The company approached Mark Aluminium Die Casting given its long standing history of producing a wide variety of aluminium die cast components, its ability to both design and manufacture bespoke Aluminium die casted products and its flexibility of manufacturing.

Once the requirements had been outlined, MADC set to work on processing the CAD models in-house, and then translating them into the first prototypes, these were then thoroughly tested. With the prototype selected and volume requirements detailed, MADC then sourced the die-cast tooling, heated up the furnaces and set to work on configuring six of the high-pressure aluminium casting machines for manufacturing the enclosures.

MADC has been producing high quality, high pressure aluminium die cast components for the automotive industry for over 30 years under the Mark Water Pumps banner, and currently produces over a quarter of a million pumps per year. The company has decided to expand its aluminium die casting operations due to the increased interest from companies wishing to re-shore their facilities, or to use suppliers based in the UK.

Benefits of re-shoring

Using a UK based company offers all the usual benefits of local supply. When dealing with a supplier abroad there can be a degree of inflexibility. Most of the time, to try and make the order more cost effective, companies order larger quantities than required to bring down the total cost per item. This however can be a false economy when a local supplier is available. Any unsold stock from that order then has to be kept secure, which means taking up much needed space in the premises, or in some cases for smaller companies a separate store needs to be rented.

On the other side, if too little is continually ordered then the cost per item increases as do the shipping costs over a number of orders. And with longer delivery times expected the ability to quickly react to potential orders diminishes. So, if you order too much you need to find a place to keep the overstock, and if you order too little, then you risk the danger of being unable to fulfil any reactive orders, and in the worst case lose custom due to this.

Plant manager of MADC, David Lewis commented: “We are very excited to have recently received significant orders for re-shoring of high pressure aluminium die cast products. With over thirty years of experience of aluminium die casting design and manufacturing we are geared up for any type of order that is required from us.”

Lewis continued: “We are winning orders because when you take all the purchase considerations into account, we are very cost competitive. We can provide design, manufacturing and testing, all under one roof, for thousands to hundreds of thousands of parts, and have a tremendous on-site stock capacity and logistics service.”

Lewis added: “When we were approached by a leading LED lighting company to provide aluminium heat sinks, it really was the perfect match. The more questions they asked regarding their requirements the more we were able to say yes to every one of them. This is all down to the experience and expertise of the guys at the factory.”

Concluding Lewis said: “We are able to provide orders of any quantity, and welcome small niche projects as well as large scale orders. We have a competitive tooling solution that helps to bring costs down for companies that wish to re-shore their manufacturing base and the best quality tooling is sourced locally for super precision applications. We can provide bespoke products to suit, such as adding mounting points and cable entry points within the casting itself, which can save hours of assembly time for our customers, and helps to provide a premium product.”

Why aluminium?

The main reason for choosing a bespoke aluminium die-cast enclosure is the massive time and cost saving during assembly that comes from having the cable entries already present and mounting points for hinges, lids and internal assemblies such terminals, larger components and other smaller components mounted to PCBs just where you want them.

Being able to assemble a product without making modifications to an enclosure saves a huge amount of time and cost, usually far more than the additional cost of creating a bespoke enclosure.

With aluminium’s corrosion resistant properties it can fend-off extreme weather conditions, and an often forgotten trait is the ease with which you can assemble using screws, bolts and all manner of fixings to it without worrying about breaking the paint surface, which frequently leads to corrosion and eventual water ingress in pressed steel enclosures.

Similar articles

More from Mark Aluminium Die Casting (MADC)

- The future metal requirements of EVs and hybrids 3rd September 2019

- Custom die cast Aluminium casings 2nd October 2017

- Aluminium Die Casting company makes light of a difficult product 13th September 2017

- How are Aluminium die cast products produced? 31st May 2017

Write a comment

No comments