Materials and Fastening

Displaying 891 - 900 of 1054

Dispensing Adhesives with Hand Pumps Reduces Cost

Threaded fastener loosening is one of the major causes of industrial equipment failure and the resulting unscheduled downtime costs industry millions of dollars each year. Threaded fasteners set and hold tolerances on assemblies ranging from light duty equipment to heavy machinery. To increase the reliability of this equipment many threadlocking methods have been developed, yet none exhibit the level of performance of anaerobic threadlocking and thread sealing adhesives.

15th September 2009

Laboratory mixing from Intertronics now non-invasive

Mixing of materials in the laboratory or for smaller production volumes is traditionally done by hand, or the use of some sort of mechanical blade, impellor or paddle to agitate the mix. These are fine in their way, being largely inexpensive, manual or simple powered tool processes, and are adequate for many mixing tasks.

11th September 2009

Reducing your Solvent Process Costs turns waste into value

At a time of increasing costs in Manufacturing a final piece of the puzzle is available to improce the viability of your Component Cleaning Process.

10th September 2009

New ultra fine emulsion for high specification printed electronics

MacDermid Autotype has launched Autotype PLUS GOLD, a photo-stencil emulsion specifically designed for high tolerance electronics screen printing. The new ultra fine emulsion is ideal for Photovoltaics, LCD displays, medical bio-sensors, and other demanding printed electronics applications.

9th September 2009

Processing Equipment Components Lined with VICTREX PEEK Polymer Resist Attack in Demanding Applications

A common method for protecting processing equipment against corrosion and chemical attack is to line the components with plastic. However, with new production methods placing higher demands on facility design and equipment, conventional plastics have rapidly reached their limits due to their lack of chemical, diffusion and abrasion resistance. High performance VICTREX PEEK polymer, with its unique combination of properties, offers a superior alternative as a lining and surface material, enabling pumps, containers, pipes and piping systems to meet the most demanding processing conditions.

7th September 2009

Anaerobic Adhesives Reduce Costs and Increase Reliability for Industries

Threaded fasteners set and hold tolerances on assemblies ranging from light duty equipment to heavy machinery. In many cases fasteners that self-loosen during equipment operation may contribute to wear and fatigue, and result in poor operating tolerances, misalignment, and sometimes catastrophic equipment failures that cost millions of dollars in unscheduled downtime each year. Various types of differential stresses such as vibration and shock, thermal expansion and contraction, and micro-movement reduce clamping force on the assembly and ultimately cause machine failure. Case after case, anaerobic threadlocking adhesive technology has proven to be more reliable and cost efficient to prevent the loosening of threaded fasteners and leakage in a variety of applications versus

mechanical fasteners such as spring washers, wire retainers and nylock nuts.

3rd September 2009

Solvent recovery and waste management reduces costs

At a time when Companies need to find extra efficiency at reduced costs, a good place to start is your manufacturing process.

2nd September 2009

Form-in-place (FIP) gaskets from Intertronics

Form-in-place (FIP) gaskets have been part of the mainstream enclosure industry for many years but the cost and physical size of robotic application has been a major constraint for SMEs – until now. Those clever people at Intertronics have focused on bench-top robotics and matched compliant gasket materials to provide low cost equipment to suit boxes or housings from 200mm x 150mm, e.g. junction boxes, terminal boxes, control boxes, electronic housings, small mechanical gearboxes or other. They have dramatically cut entry cost to around £4,000 on the smallest – with larger equipment running right up to 800mm x 600mm machines.

28th August 2009

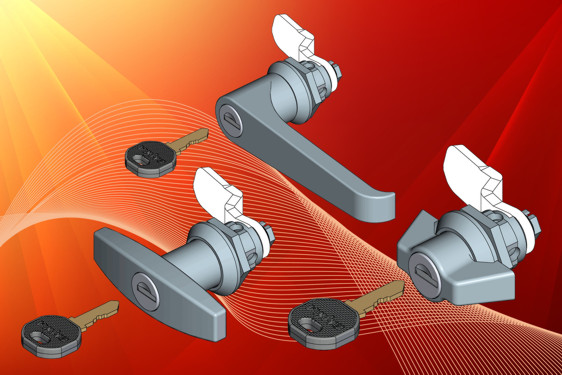

Stainless steel handles from EMKA for arduous applications

Specialist panel builders seem to love the modular EMKA product range so we expect their new key locking stainless steel handles will also be well received. These wing, T and L handles in AISI 316 grade stainless come at a high specification for material and sealing at IP65. Standard EMKA modular cylinders and keys complete the package for use in all sorts of arduous, wash-down, corrosive or otherwise very difficult environments.

25th August 2009

Materials and Fastening documents

Product Centre Updates

2024 World Battery & Energy Storage Industry Expo (WBE)

8th August 2024

China 1st and 2nd Floor, Area A, China Import and Export Fair Complex