TRUMPF LTD

Address:

PRESIDENT WAY

AIRPORT EXECUTIVE PARK

LUTON

BEDFORDSHIRE

LU2 9NL

United Kingdom

AIRPORT EXECUTIVE PARK

LUTON

BEDFORDSHIRE

LU2 9NL

United Kingdom

TRUMPF LTD articles

Displaying 1 - 20 of 29

Investment keeps 2020 vision in focus

One of the UK’s largest precision sheet metal fabricators is hoping that a £1m investment will help double its turnover by 2020. Alpha Manufacturing has ordered a TruBend Cell 7000 high speed robotic bending cell and TruPunch 5000 CNC punching centre from TRUMPF. The investment complements the acquisition last year of a TRUMPF TruLaser 3030 fibre CNC laser profiling centre.

11th October 2017

Open House event welcomed over 200 visitors

Taking place on 13th to 15th June 2017, the annual TRUMPF UK Open House proved itself to be a real success in more ways than one. For instance, not only did the three-day event attract more than 200 people through its doors, but orders in excess of £2m were secured. In addition, the high level of interest gives a very positive business outlook. The event demonstrated yet again why it is considered among the highlights of the sheet metalworking calendar.

18th July 2017

TRUMPF reshapes after sales service structure

To reinforce its commitment to product development and customer service support operations, Luton-based TRUMPF, has made a major structural change in its after-sales organisational structure. Following extensive consultation with its customers and utilising the latest agile management concepts, TRUMPF is moving away from centralised service and technical support management, in favour of a regionalised structure.

5th July 2017

TRUMPF holds an Open House this summer

Across a three day period in June 13th-15th, TRUMPF are inviting visitors to its 2017 Open House at the TRUMPF Technology Centre in Luton, to see how it continues to innovate to help UK manufacturers be competitive and successful. Guests will be introduced to what’s new in TRUMPF punching, laser and bending technologies and be invited to take part in a programme of seminars focussed on efficient and smart production.

13th April 2017

Machine punches 50% above its weight

With its investment in the latest TruPunch 1000 CNC punching machine from TRUMPF, Birmingham-based lighting manufacturer Candela Light has seen a 50% increase in production speed over its two previous turret punch presses. The machine was purchased alongside a TRUMPF TruBend 3066 CNC press brake and the latest TRUMPF TruTops Boost software that allows the company to generate programmes at the touch of a button.

2nd February 2017

The fastest bending show on earth

The TRUMPF In-Tech Open House at their Luton Technology Centre always provides a UK launch platform for new manufacturing technology and this year’s event is no exception. Indeed In-Tech 2012 will introduce three new machines – the world’s fastest bending cell, a highly affordable fibre guided laser machine for thin sheet processing and a brand new compact automation solution.

7th September 2012

SOUTHERN MANUFACTURING 2012, 15th & 16th February, Farnborough

In previous years at Southern Manufacturing, TRUMPF has focused on its leadership in laser technology for product marking. The 2012 event will be no exception but in addition the company will also demonstrate its prowess in precision bending with one of its outstandingly productive TruBend machines.

28th November 2011

Any Material, Any Thickness, Any Time

As the stockholder of a wide range and thicknesses of materials, ADS Laser in Leicester has always advertised its capacity to turnaround sheet metalworking orders quickly. However, with the company’s acquisition of the new TRUMPF TruLaser 3030 L20 – formerly the TruLaser 3030 NEW – it has taken this ability into a different league.

30th November 2010

Southern Manufacturing 2011 Stand no. L37

The laser, which celebrated its 50th anniversary in 2010, is a technology in which TRUMPF is a world leader both as a manufacturer and an innovator. The company’s laser programme encompasses rod, fibre, disk, diode and CO2. It applies this technology to a range of production processes but at Southern Manufacturing 2011 TRUMPF focuses on just two - micro machining and laser marking.

29th November 2010

TRUMPF Technology Days

7th – 9th December 2010

There is hardly a manufacturing application that isn’t suitable for laser technology so TRUMPF has scheduled a 3-day technology event at its Luton Technology Centre for anyone wishing to evaluate the latest industrial laser processes for their production needs. The subjects to be covered are …

12th November 2010

Trulaser Chosen For Its Superior Piercing Technology

Accurate Laser recently opened its second subcontract laser cutting company in the UK. The success of its quick turnaround, small batch manufacturing facility in the West Midlands has led to the replicating of this proven business model in Leeds. Growth is clearly anticipated and the investment in a TruLaser 3030 is seen as an essential component to the future success of the business.

2nd November 2010

Thin Cuts, Fat Earnings

For job shops and OEMs who need to cut thin sheet parts, the good news is that they can now reduce production costs on these components by up to 20% with TRUMPF’s new 2D laser processing system, the TruLaser 5030 with fiber-guided TruDisk solid state laser. Thanks to its high dynamics, the machine makes full use of the solid state laser’s advantages and achieves very high cutting speeds in thin sheet.

26th August 2010

SIZED UP LASER CUTTING

TRUMPF has developed a 2D laser machine for the processing of extra large sheets, up to 16 x 2.5m. Based on its twin-headed TruLaser 7040, the TruLaser 8000 comes with a range of options. In addition to the 4 x 2.5m pallet changer a special large sheet version is available that allows for parallel loading and unloading of sheets up to 12m long during production.

2nd July 2010

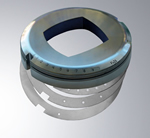

TRIPLE COMBINATION

One laser for two different machines, this is the concept behind the new TruMatic 3000 Fibre punch/laser combination machine. It shares a fibre-guided TruDisk laser with the TruLaser Robot 5020 cell in the TRUMPF LaserNetwork, an arrangement that significantly increases the utilization rate of the beam source.

27th May 2010

.jpg)