Georg Martin GmbH

Address:

Martinstr. 55

Dietzenbach

63128

Germany

Dietzenbach

63128

Germany

Georg Martin GmbH articles

Displaying 1 - 5 of 5

Freely configurable shim kits for tolerance compensation

Many installation sketches and technical drawings contain the remark “Adjust during assembly”. To ensure that this does not become a nerve-racking and time-consuming procedure, Georg Martin GmbH is now offering customer and application-friendly assorted mini assembly kits in its M-Tech P product line for efficient tolerance compensation when assembling components. What the user gets is an individually compiled set of fine adjustment films precisely coordinated to fit every joint which can be used as required during assembly and maintenance work. Users can choose here as desired between mini assembly kits with foils made of stainless steel, steel, NF metals or composite materials with individual thicknesses of 10 µm to several millimetres. Martin also allows the customer to choose more or less at will with regard to quantities, arrangement, sequence, shape and even the materials mix. There are also the mini assembly kits which come as “tear-off calendars” with perforations, edge-bonded or loosely bundled.

7th September 2015

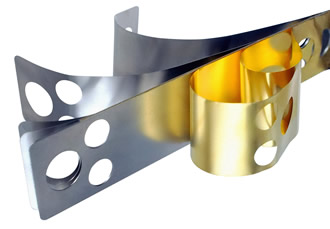

Georg Martin provides high-quality M-Tech spring strip parts for friction discs

Today, manufacturers of friction discs require very thin precision-drawn parts to apply their special coatings. Georg Martin GmbH provides these as precision-fitting pre-products which can be further processed directly. No matter whether it’s a prototype, a pilot series or a large series – on the basis of its flexible production, the Georg Martin can provide virtually any batch size quickly and punctually.

21st September 2012

Layered metal shims cut assembly times and costs

Wherever components are joined into functioning assemblies, layered sheet metal shims from Georg Martin help cut assembly times and costs. For example for Swiss press manufacturer Beutler Nova, who use four pretensioned, vertically installed linear guide units for the twin-stand construction of their AZ 630 blanking press with a single connecting rod.

13th July 2012

Quick final assembly and cross-process savings effects – Shims for tolerance compensation score points as a lean management tool

In many companies, Lean Management remains a well-intended management theory because there are no concrete instruments for its practical realization. What many people do not realize, however, is that the implementation of small measures can produce astounding results. A good example of this is the use of shims to compensate tolerance in the production of subassemblies, thus triggering great effects across all areas of the company.

13th June 2012

Product Centre Updates

2024 World Battery & Energy Storage Industry Expo (WBE)

8th August 2024

China 1st and 2nd Floor, Area A, China Import and Export Fair Complex