Arnold Umformtechnik GmbH & Co. KG

Address:

Carl-Arnold-Straße 25

Forchtenberg

74670

Germany

Forchtenberg

74670

Germany

Arnold Umformtechnik GmbH & Co. KG articles

Displaying 1 - 16 of 16

Cleancon - Technical cleanliness of fasteners

In modern systems in the automobile industry and electronic equipment, particles as small as 500, 200 or even 100 microns can cause malfunctions or total system failure. In many cases these problem particles on components originate from fasteners. The Cleancon cleanliness concept developed by Arnold Umformtechnik provides a process that eliminates the risk of system failure due to particles by taking an integrated approach from fastener production to assembly.

12th March 2013

Thread forming slashes costs by 88%

Taptite 2000 generation of thread forming screws combines efficiency advantages with process reliability. A total cost saving of up to 88% can be achieved in threaded fastener assembly. The Taptite 2000 generation of thread forming screws from Arnold Umformtechnik GmbH & Co. KB makes a fundamental contribution to cost reduction in threaded fastener systems. Based on experience, costs savings of up to 88% can be achieved in threaded fastener assembly.

26th February 2013

Arnold Umformtechnik testing centre boosts customer proximity

With its Fastener Testing Centre, Arnold Umformtechnik offers its customers and other interested parties a full range of services for all aspects of the inspection, testing, measuring and qualification of metallic components. This application-specific division combines high-quality analysis with expert assessment and advice.

19th September 2012

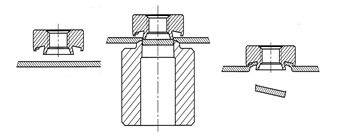

System solution with RIVTEX

The RIVTEX system solution from Arnold Umformtechnik and Arnold & Shinjo is a high-quality alternative to conventional welding. It cuts parts assembly costs whilst assuring every quality requirement. With the RIVTEX system studs and nuts are pressed into the ready-to-assemble sheet metal parts such that they do not fall out and are characterised by high twisting moments and press-out forces.

13th June 2012

Cleancon: Innovative cleanliness concept for fasteners compliant with VDA 19

The VDA 19 guideline and the ISO 16232 standard define new requirements for the automobile industry for verifying technical cleanliness. To fulfil these requirements, manufacturers must identify and quantify any particle contamination that is present. The Cleancon cleanliness concept from Arnold Umformtechnik goes a step further and provides a process that encompasses cleanliness requirements all the way from production to the customer application.

21st May 2012

Automotive supplier Hetal-Werke tests Arnold ATP studs

The automotive division of Hetal-Werke is intensively looking for alternatives to conventional joint technologies. In the future, ATP TriPress fasteners from Arnold Umformtechnik are expected to be used in place of conventional weld-on studs. These press-in studs match the requirements profile of the company, which specialises in the full scope of kinematic subassemblies and hinges in the passenger car seating area.

14th May 2012

Flowform screws

Arnold Umformtechnik developed Flowform screws in response to the increasingly complex requirements for sheet metal joining. These trilobal (triangular) screws utilise the technology of flow-hole forming in the fabrication process. Flowform is a cost optimised solution that offers higher process reliability for threaded fastener joints and considerable advantages over alternative sheet metal joining methods: ease of loosening, accessibility, positioning, reassembly with threaded fasteners, freedom from fabrication residues.

2nd December 2011

Cleancon Concept

The number of vehicle failures due to electronic components is increasing every year. Electronic components are involved in nearly half of all emergency assistance calls received by the German motorists´ association ADAC. Often coming from screws, microscopic contamination particles on interconnects regularly cause failures in control units. To solve this problem, Arnold Umformtechnik has developed the Cleancon concept.

5th October 2010

REMFORM screw reduce the cost of plastic components assembly

Remform screws from Arnold Umformtechnik GmbH & Co. reduce the overall assembly cost of plastic parts as they do not require nuts or inserts. They furthermore ensure the highest levels of assembly security, due to a specific design that creates a large difference between the forming torque and the stripping torque. The main application of REMFORM for plastic parts assembly is the automotive industry.

22nd June 2010

Remform and ATP screws

Arnold provides two new reliable and cost-effective assembly methods to answer to the continuously

evolving use of plastics. Remform screws is a solution for detachable plastic parts joints whereas Arnorld Tripress (ATP) are dedicated to permanent joints for ductile light metals or plastics.

4th May 2010

Keeping it clean - technical cleanliness in fastening technology

In view of the growing importance of “technical cleanliness” Arnold, working closely with the Fraunhofer Institute, has set up a cleanliness compliance procedure for fasteners – “Cleancon®”. What have always been rather general cleanliness requirements for components can now, for the first time, be precisely categorised. Arnold has set up its own test laboratory which develops and adapts test specifications to stipulate the degree of component cleanliness required in production and throughout the entire supply chain.

30th May 2008

Aluminium replaces steel

The increasing importance of magnesium as a construction material requires an inspired pairing of materials when it comes to screw fastenings. Alufast® aluminium screws from Arnold Umformtechnik have proved to be particularly excellent for making screw fastenings on housing sections, brackets and stiffeners made of magnesium.

30th May 2008

Product Centre Updates

2024 World Battery & Energy Storage Industry Expo (WBE)

8th August 2024

China 1st and 2nd Floor, Area A, China Import and Export Fair Complex