Komatsu aims to contribute in closing UK skills gap

Komatsu a Japanese company named after the city Komatsu, which translates to ‘small pine tree’ works in manufacturing construction and mining equipment and industrial machinery. Komatsu has a big presence in England with a large manufacturing facility in County Durham, which employs a large number of local people.

Back in 1930 the company started manufacturing, and produced the T25 an agricultural tractor. In 1968 Komatsu produced its first hydraulic excavator, and now the company has 93 manufacturing plants worldwide.

Its latest and largest product, the P&H 9020C dragline, measures 67.7m high, includes 55-93m3 bucket capacity, 90-125m boom length and an integrated centurion electrical control system for supporting maintenance and performance-optimising systems. This dragline also includes intelligent sensors and I/O devices that monitor and control the dragline to enable machine health and reporting, as well as performance enhancement systems. Furthermore advanced communication and monitoring links to both the mine management and maintenance reduced down-time.

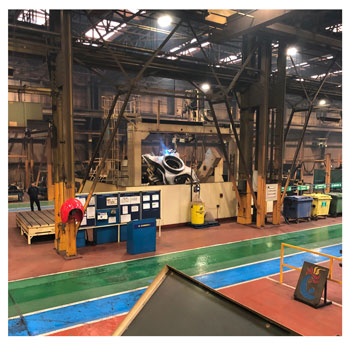

The company is made up of around 91% construction and mining equipment, and nine percent industrial machinery. Komatsu is the second largest manufacturer of construction equipment in the world. The Komatsu UK branch produces the whole range of equipment from 20-70 tonne excavators.

In the UK Komatsu has a small number of import machines from Japan that are then transformed to fit UK specifications. The UK plant in County Durham officially opened back in 1987, and now employs over 175 local people, in fact around 50 employees have worked there since the plant was originally opened. John Lawson, Public Relations Officers said: “Komatsu invest a lot in their employees and like to hold onto them, it lets them grow with the company which works for both parties.”

Komatsu has just entered its 30th year of production, from the DASH 3 back in 1987 up to the DASH 11 produced in 2014. Lawson added: “For Komatsu it’s all about the technology, and the fuel saving emissions.” A lot of consideration is taken when it comes to production as Komatsu aims to look carefully at the design of the machine, and always looks at the safety of the driver.

The County Durham branch of Komatsu currently produces around 12 machines per day, and has a yearly target of around 2,000. Lawson added: “Komatsu prides itself on asking for constant improvement and feedback from its employees, which essentially gets them involved, changes the culture around the work place and makes them feel recognised. It’s all about team work.”

In fact over the last 18 months Komatsu UK has taken on over 100 extra employees to keep up with the production demand. Paul Blanchard the Managing Director of Komatsu UK said: “Europe has shown a high demand over the past year or so, and this has improved the market demand in general. Last year we saw a surge in demand from North America so we hope it continues in this direction.”

Komatsu is used a lot in road construction, so there will always be that demand. Blanchard added: “Although electrification is an upcoming factor we are not really looking at it yet, we have a couple of hybrid machines, but we are more about getting fuel consumption down. A lot of ongoing work on automation is now being pushed by smart consumption. Komatsu are in the right place for this, -however, what we are struggling on is engineers, especially software engineers. It is clear there is a skills shortage, and that’s why it is important for us to have this plant here in the UK, to encourage more local people into the industry, and increase on the number of engineers here in the UK.”

Similar articles

More from Komatsu Seiren

- Komatsu aims to contribute in closing UK skills gap 8th April 2019

Write a comment

No comments