£2.4 million machine tool sales from DMG productivity days

23rd June 2011

Source:

DMG (UK) Ltd

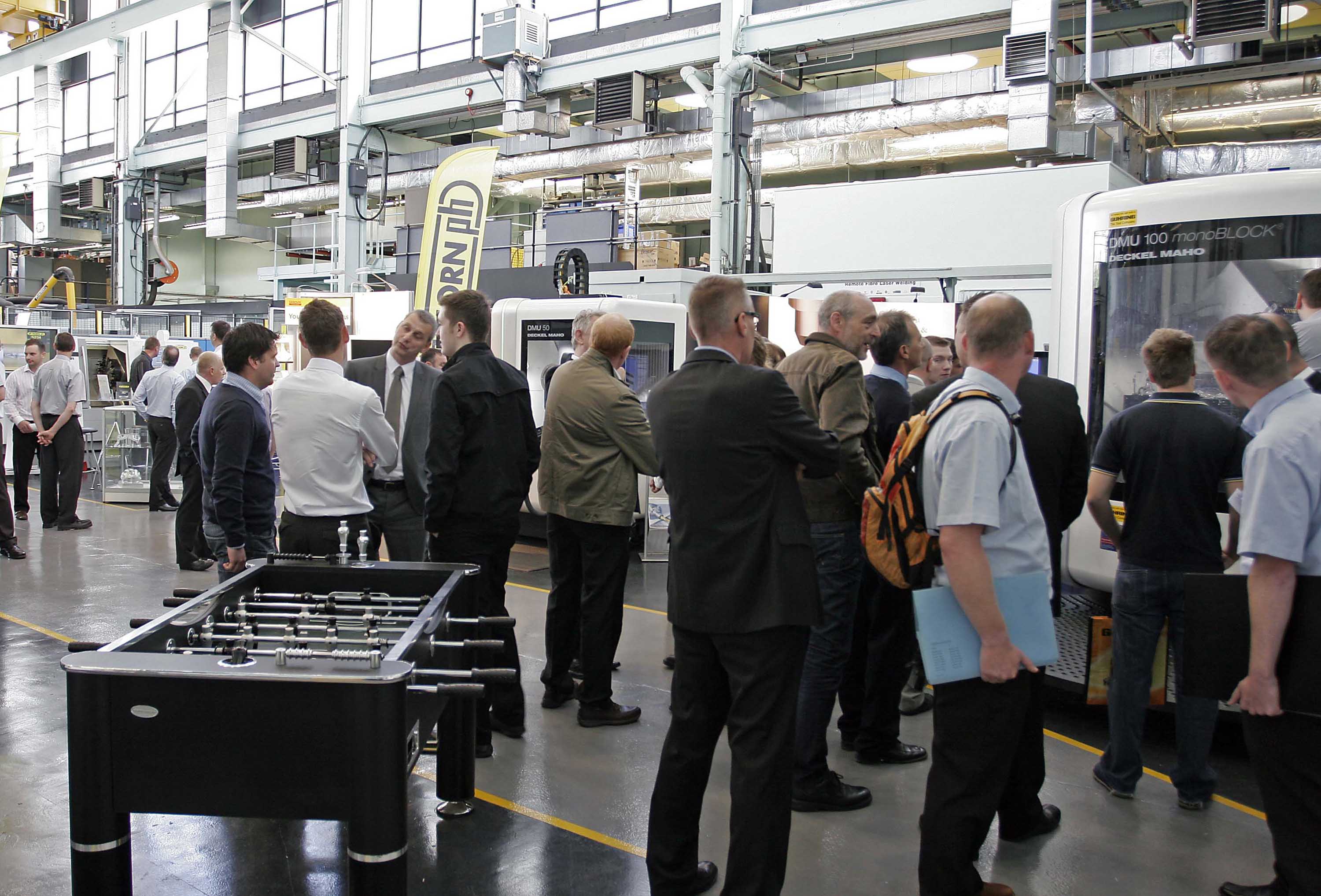

A dozen machines with an average order value of £200,000 were sold at the productivity days held by DMG at the International Manufacturing Centre, University of Warwick, from 7th to 10th June 2011. The orders comprised turning and 5-axis machining centres, including some from the manufacturer's new, entry-level, EcoLine range.

Richard Watkins, Managing Director, commented, Although the number of visitors – nearly 200 – was fewer than in previous years, their level of seniority was high. It resulted in a very positive open house and an encouraging order intake.

There was a lot of interest shown by companies over the four days, particularly first- and second-tier suppliers to the aerospace, F1 and medical sectors, which should result in further business. Four fifths of enquiries were for 5-axis machining centres and most of those were for models with integral turning capability.

Focus was also on larger machine tools for wind turbine and other powergen component manufacture. Companies were asking about lathes for turning parts two and three metres long or prismatically machining them in the range 1.5 to 2.5 metres cube.

Tooling partners Sandvik Coromant, Guhring and PH Horn were in evidence at the open house, as well as NX CAM and associated product lifecycle management software company, Siemens PLM and solution partner TTL, a specialist in CAD/CAM and adaptive CNC machining technology. Seminars were held on two of the mornings explaining the features and capabilities of the Heidenhain iTNC530 and Siemens 840D control systems.

Speaking generally about current market conditions, Mr Watkins said that while sales are strong – DMG UK having the level of sales at the half-way point in 2011 that it envisaged at the start of the year – there is undoubtedly still fragility in the manufacturing sector.

Whereas in buoyant times, companies might have invested speculatively in the hope of winning new business, these days they are waiting until contracts are signed before spending. Naturally they then want the machine(s) very quickly, which can be problematic. Production at all of DMG's factories around the world is currently at full bore.

DMG at EMO 2011, Hannover

Looking forward to the Hannover EMO show in September, there will be the launch of an extension to the DMU eVo 5-Axis machining centre programme to include a nominal one-metre-cube model at the top end of the size range.

These early entry machines cost 30 to 40 per cent less than 5-axis machining centres of equivalent size at the top of DMG's product programme, according to Mr Watkins. While very capable in terms of functionality, they can be a 'sledgehammer to crack a nut' for some applications, whereas the new eVo range is ideally priced for rapid return on investment in subcontract shops further along the supply chain.

There will also be new, larger models introduced at EMO in the monoBLOCK range of universal, 5-sided / 5-axis machining centres, where sizes 85 and 105 will be introduced. Again, this reflects the trend towards demand for equipment on which to manufacture bigger parts for power generation and aerospace applications.

A further theme on the DMG stand will be the inclusion of turning on 5-axis machining centres, with eVo machines and monoBLOCKs sporting this facility for the first time. Currently, only duoBLOCK machines have mill-turning capability.

There are 20 product lines including laser and ultrasonic technologies and over 300 model permutations in DMG's product portfolio, with 40 models and 120 derivatives of 5-axis machining centre alone. Mr Watkins concluded by stressing that it is their responsibility to make sure that customers receive the right production solution and the correct level of technology to suit their needs. With such a variety of machines at the disposal of DMG sales managers, there is every reason why they should deliver this result every time.

Comments on the Productivity Days from Mike Dinsdale Managing Director, Guhring Ltd

Supporting such a DMG event was a first for Guhring and proved to be a very worthwhile marketing exercise. Visitors certainly excelled in quality. Guhring was able to interest some progressive manufacturing companies in the use of the latest rotary cutting tools on highly flexible DMG machine tool platforms.

During a week when there was excellent news for UK manufacturing from Nissan, BMW and Jaguar Land Rover, it was a pleasure to see representatives from two of these key companies in attendance.

UK manufacturing is very busy and it was difficult to gain a larger attendance due to work commitments, but all those that did attend commented on the benefits that could be gained through the application of the best tooling from Guhring, Sandvik and PH Horn, suitably put to the test on a selected range of very good DMG machines.

Many comments were made to Guhring by visitors about the differences between dynamic events such as the DMG Open House and the static tooling exhibitions. The result was, unsurprisingly, a 100 per cent vote in favour of the open house format.

The DMG event aroused incredible interest to ensure that people went away with a memory of witnessing unbelievable machining performance and productivity benefits. Such benefits are crucial to ensuring that UK engineering survives and prospers.

All in all an excellent event, with great organisation and support from the DMG team. Guhring looks forward to participating in similar events in the future.

There was a lot of interest shown by companies over the four days, particularly first- and second-tier suppliers to the aerospace, F1 and medical sectors, which should result in further business. Four fifths of enquiries were for 5-axis machining centres and most of those were for models with integral turning capability.

Focus was also on larger machine tools for wind turbine and other powergen component manufacture. Companies were asking about lathes for turning parts two and three metres long or prismatically machining them in the range 1.5 to 2.5 metres cube.

Tooling partners Sandvik Coromant, Guhring and PH Horn were in evidence at the open house, as well as NX CAM and associated product lifecycle management software company, Siemens PLM and solution partner TTL, a specialist in CAD/CAM and adaptive CNC machining technology. Seminars were held on two of the mornings explaining the features and capabilities of the Heidenhain iTNC530 and Siemens 840D control systems.

Speaking generally about current market conditions, Mr Watkins said that while sales are strong – DMG UK having the level of sales at the half-way point in 2011 that it envisaged at the start of the year – there is undoubtedly still fragility in the manufacturing sector.

Whereas in buoyant times, companies might have invested speculatively in the hope of winning new business, these days they are waiting until contracts are signed before spending. Naturally they then want the machine(s) very quickly, which can be problematic. Production at all of DMG's factories around the world is currently at full bore.

DMG at EMO 2011, Hannover

Looking forward to the Hannover EMO show in September, there will be the launch of an extension to the DMU eVo 5-Axis machining centre programme to include a nominal one-metre-cube model at the top end of the size range.

These early entry machines cost 30 to 40 per cent less than 5-axis machining centres of equivalent size at the top of DMG's product programme, according to Mr Watkins. While very capable in terms of functionality, they can be a 'sledgehammer to crack a nut' for some applications, whereas the new eVo range is ideally priced for rapid return on investment in subcontract shops further along the supply chain.

There will also be new, larger models introduced at EMO in the monoBLOCK range of universal, 5-sided / 5-axis machining centres, where sizes 85 and 105 will be introduced. Again, this reflects the trend towards demand for equipment on which to manufacture bigger parts for power generation and aerospace applications.

A further theme on the DMG stand will be the inclusion of turning on 5-axis machining centres, with eVo machines and monoBLOCKs sporting this facility for the first time. Currently, only duoBLOCK machines have mill-turning capability.

There are 20 product lines including laser and ultrasonic technologies and over 300 model permutations in DMG's product portfolio, with 40 models and 120 derivatives of 5-axis machining centre alone. Mr Watkins concluded by stressing that it is their responsibility to make sure that customers receive the right production solution and the correct level of technology to suit their needs. With such a variety of machines at the disposal of DMG sales managers, there is every reason why they should deliver this result every time.

Comments on the Productivity Days from Mike Dinsdale Managing Director, Guhring Ltd

Supporting such a DMG event was a first for Guhring and proved to be a very worthwhile marketing exercise. Visitors certainly excelled in quality. Guhring was able to interest some progressive manufacturing companies in the use of the latest rotary cutting tools on highly flexible DMG machine tool platforms.

During a week when there was excellent news for UK manufacturing from Nissan, BMW and Jaguar Land Rover, it was a pleasure to see representatives from two of these key companies in attendance.

UK manufacturing is very busy and it was difficult to gain a larger attendance due to work commitments, but all those that did attend commented on the benefits that could be gained through the application of the best tooling from Guhring, Sandvik and PH Horn, suitably put to the test on a selected range of very good DMG machines.

Many comments were made to Guhring by visitors about the differences between dynamic events such as the DMG Open House and the static tooling exhibitions. The result was, unsurprisingly, a 100 per cent vote in favour of the open house format.

The DMG event aroused incredible interest to ensure that people went away with a memory of witnessing unbelievable machining performance and productivity benefits. Such benefits are crucial to ensuring that UK engineering survives and prospers.

All in all an excellent event, with great organisation and support from the DMG team. Guhring looks forward to participating in similar events in the future.

Similar articles

More from DMG (UK) Ltd

- First UK sale of jointly developed DMG / MORI SEIKI machine 4th May 2012

- New 5-Axis Machining Centre With Turning Capability 1st May 2012

- Heavy Duty Turn-Mill Centre For Components Up To Three Metres Long 14th November 2011

- Emo 2011 DMG and MORI SEIKI Collaboration Nearing Fruition 31st October 2011

Product Centre Updates

2024 World Battery & Energy Storage Industry Expo (WBE)

8th August 2024

China 1st and 2nd Floor, Area A, China Import and Export Fair Complex

Write a comment

No comments