Direct drive robotic arms support lean automation

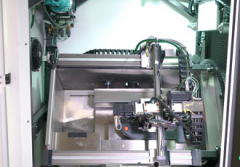

Expanding its range of cost-effective modular robolink systems, igus introduces the robolink D direct drive articulated arm – a tougher, more durable solution compared with remote drive versions – supporting lean automation. Typical robotic applications are repetitive tasks, such as on assembly lines and pick-and-place equipment. To support this, the new robolink D system is completely modular due to the direct drive situated within each joint, which helps achieve significant cost savings.

The new robolink is driven by a worm gear drive and a NEMA 17 or 23 stepper motor directly in the joint; these can be easily controlled using any commercially available control module. Based on self-lubricating iglidur PRT slewing ring bearings, robolink D system is available in three sizes, which can be combined to create articulated arms from one to as many as six Degrees Of Freedom.

The sea-water resistant, maintenance and corrosion-free bearings of the robolink® D makes it equally well-suited to a variety of other applications, ranging from underwater vehicle operations to humanoid robots for explosive equipment handling.

Similar articles

More from igus UK Limited

- From garage business to world leader: igus founders celebrate 90th birthday 22nd June 2021

- VOTW - Metal out plastic in! 10th June 2021

- igus robot works alongside agri-tech startup 18th May 2021

- Tribo-polymers increase machine service life and efficiency 10th May 2021

ed.jpg)

Write a comment

No comments