Alignment checking sometimes turns into restarts

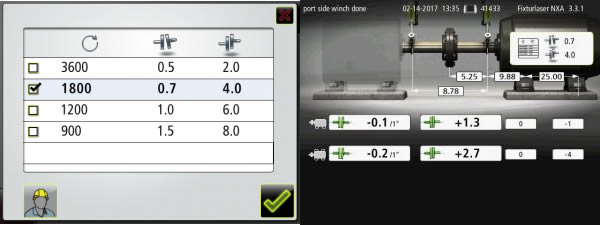

Recently, a Fixturlaser NXA Pro training class performed an alignment check of a winch driven by an 80HP, 1800RPM, DC electric motor with a gear style coupling. The initial results revealed a misaligned machine, with a vertical angularity over 13 times the tolerance of 0.7mils/1” (1.0mil=0.001”), vertical offset six times tolerance of 4.0 mils. The horizontal angularity was almost four times the tolerance; the horizontal offset was close ‘but not quite.’

As 354mils of shims needed to be removed from both rear feet and 118 taken out of the front feet, the class removed all shim packs to take an inventory of the number and condition of the shims under each foot.

What they found was a mix of shim materials (brass, plastic and steel) and all were of questionable condition. (Not worth reusing).

All feet had enough shims under them to lower the motor the amount indicated by the initial alignment results however there was 50mils more shims under the right rear foot than under the left rear. The front feet only had a 3mil difference.

At this point the class discussed how best to proceed. Some noted (correctly) that with the severe misalignment there was perhaps coupling influences and they needed to start from square one with a better rough-in to minimise coupling influences. Others noted the motor feet design and were concerned (correctly again) about possible soft foot issues.

The class agreed to start at the beginning and roughed in the vertical with new clean shims of the same material then used the laser to rough-in horizontally (the sensors were still mounted to shafts and the system on), checked for obvious soft foot, properly tighten the hold down bolts, and performed a final soft foot check. Surprisingly there was very little soft foot, which was corrected.

After taking care of the alignment fundamentals up front (pre-alignment steps), the precision shaft alignment was completed in two Verti-Zontal Compound Moves with all coupling values better than the 1800RPM tolerances with three out of four better than 3600RPM tolerance.

Total time from initial results to final results was three hours (two hours working with a one hour lunch break).

When necessary start over at the beginning and follow the Verti-Zontal Process. You will save time and you will typically be finished in two moves or less.

Similar articles

More from Fixturlaser AB

- Vibration analysis: Where to start? 8th January 2020

- Is this soft foot or are you pulling my leg? 15th February 2018

- It's not the machine, it's you! 4th July 2017

- Roughing in before precision shaft alignment 2nd June 2017

Write a comment

No comments