Harsh Environment Challenges Are No Problem For Morgan Ultrasonic Sensors

Sustained investment and innovation are once again paying off for Morgan Advanced Materials, this time in the field of sensing solutions. Morgan can now offer customers customised and optimised sensors for use in harsh environments. Products available include liquid and gas flow measurement and level / distance detection, while additional ultrasonic assessments can be made including the identification of fluid “quality” and chemical concentration. This marks a major step forward in a number of markets which each present a unique set of technical challenges.

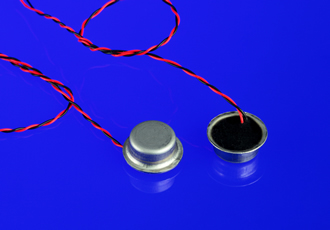

The latest example of Morgan's class-leading expertise in harsh environment technology comes in the form of its ultrasonic level sensors, which are applicable to a surprisingly large and diverse range of settings. These include automotive, aerospace, rail, marine, medical, pharmaceutical, industrial, chemical, oil and gas and food / brewing applications. One of the reasons why ultrasonic sensors are so popular when used with liquids is their inherent tolerance to contamination from particles, ice crystals, foam and fluid opacity.

In light of this market diversity, Morgan's harsh environment solutions are manufactured to give optimal performance in each specific application. For example, in the aerospace sector, accuracy in distance and level measurement has been demonstrated in service for the last 20 years. Aerospace requirements typically include tolerance to shock and vibration, large temperature variations and lightning strikes without compromise to sensor performance. When used in fuel and liquid handling technology, sensors must also be able to withstand permanent immersion in aggressive fluids and high and / or low pressures. They may be characterised and optimised over a wide range of operating conditions to ensure continuous and reliable operation. In subsea environments, sensors must resist extreme levels of pressure, which make great demands on the ceramic materials used and the toughness and durability of the units manufactured.

Tony Beswick of Morgan believes the company's ability to work closely with customers who require harsh environment solutions, from concept and preliminary trial phases right through to optimisation and qualification phases, offers a wealth of possibilities for both parties involved. "Our engineering, design and development expertise enables us to provide customised solutions that exactly meet customers' needs. We know harsh environment markets well, and have spent years deliberately extending our experience and capabilities in this area. As a result we can optimise each of our products for its specific application, for example complimentary elements may be added or materials revised according to the destined environment. However, there is no room for complacency and there may well be applications for our capabilities that we have not thought of yet. If anybody wants us to solve a novel challenge within a harsh environment, we would be delighted to hear from them," he says.

Morgan Advanced Materials has its own cutting-edge assembly, integration and test facilities, so harsh environment technologies can be tested, optimised, and characterised across wide operational conditions to make sure that the precise requirements of each customer are met.

Similar articles

More from Morgan Advanced Materials plc

- Safety certification leads to food packaging breakthrough 13th October 2017

- Prototype capability announced for custom piezoceramic micro tubes 20th December 2016

- Grinding capability boosted for greater pump efficiency 28th November 2016

- Global maritime security sector leads to boost in industry 16th November 2016

Write a comment

No comments