Water wheel bearings improve efficiency and reliability

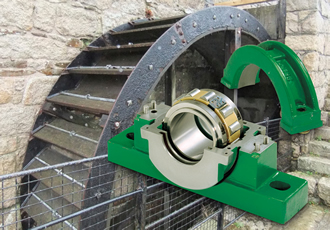

For any power generation project, efficiency and reliability are two very important characteristics. So, when a 2 star Michelin restaurant in Belgium decided to refurbish its water wheel generator, it needed to source new bearings. With such close proximity to water, the new bearings would also require excellent sealing properties, which led to the installation of a Revolvo split roller bearing (SRB).

The restaurant, located in the south of Belgium, planned to replace the existing steel water wheel with a new, more efficient, glass-reinforced nylon design. The aim of the project was for the new water wheel to produce sufficient electricity to power the restaurant, with any surplus being fed back into the local grid and generating an additional income stream.

The project began with a Revolvo design engineer visiting the site, accompanied by the renewable energy scheme’s designer, in order to determine the exact operating conditions and requirements of the client. It was clear that the Revolvo SRB would be an ideal solution for this application and both engineers concluded their calculations and designs on this basis.

From technical, economic and pure design perspectives, SRB split roller bearings offer a host of advantages compared to solid types. The simplicity of fitting a split roller bearing, compared to a solid bearing, is a major factor in its longevity. Because they can be removed and replaced by simply supporting the shaft, there is no need to lift the shaft, or obtain access to the shaft ends. This eliminates the need for expensive and awkward to handle lifting equipment. This feature is extremely valuable for all applications, especially regarding large machines, where sheer size and weight is a barrier to fast and cost effective servicing.

This particular application clearly required exceptional sealing properties from the bearing, which was fitted with a Walker Seal arrangement with a single garter lock spring and retaining plate to provide the highest protection against water ingress. The seal design has subsequently been tested following adverse weather with increased the river level and partially submerged the bearing. Despite these poor condition the bearings have continued to perform faultlessly.

Adrian Menzies, Revolvo’s Sales and Marketing Director, comments: “Revolvo has a very successful history of installing bearings in applications where they will be submerged in water, or much worse. Thanks to a very effective sealing system our bearings are capable of surviving far longer than traditional bearings with no more than basic maintenance required. Another advantage of the SRB is that when they do reach the end of their life they are very easy to replace.”

Since the project was completed, the client has expressed his satisfaction with the overall solution, which has performed to specification. In the mean time, the designer of the water wheel energy generator has also appreciated the benefits of the Revolvo SRB and is looking at future projects where this design will bring additional benefits to other clients.

Similar articles

More from Revolvo Limited

- Revolvo delivers bespoke bearing solution for Thames Water 9th December 2014

- Water wheel bearings improve efficiency and reliability 4th December 2014

- Split Roller Bearing design - Making the best choice 18th September 2014

- Revolvo SRB bearings accommodate misalignment without risking early failure 31st October 2012

-(1)ed.jpg)

Write a comment

No comments