Maintenance-free chains designed for conveying systems

Branded maintenance-free roller and conveyor chains have been introduced by iwis, named the Megalife range. The special characteristics of the Megalife chains allow longer replacement intervals and reduce maintenance costs and down-times of conveying systems. The chains are used wherever relubrication is not possible or disadvantageous, for example in dry ambient conditions and on installations with restricted maintenance access.

This includes conveying systems and applications in the packaging and food industry, in textile machines, in the printing industry, in paper processing and bookbinding, in the electronics industry, in printed circuit-board production, in wood, glass and ceramic processing industries and in medical engineering.

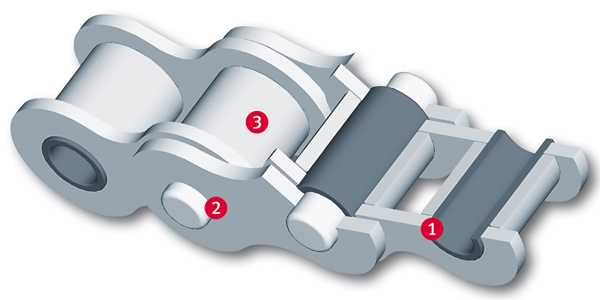

Megalife chains feature seamless sintered bushes made from a material developed specially for this product. For enhanced tribological properties, the bushes have been hardened and specially treated. The pin features a wear-resistant, friction-optimised surface coating, and the seamless roller has a corrosion-protected surface that is also wear-resistant. Thanks to these properties, the Megalife chains have a longer service life and greater strength than conventional low-maintenance chains.

The components are nickel-plated for corrosion protection and can be used in a temperature range from -40 to 160°C. The maintenance-free chains can be supplied dry or with additional special lubrication to suit any application.

The Megalife I series products are suitable for normal chain applications without relubrication at speeds of up to 3m/s. Under certain conditions, the chains are entirely maintenance-free, can be easily dismantled and can be used in corrosive environments. Using the same range of attachments as iwis’ standard conveyor chains, the Megalife chains are fully compatible with the standard products. As well as roller chains, the Megalife I series also includes transfer chain, accumulation chain and grip chain variants.

The Megalife II series offers a solution for demanding applications with high-speed chain drives running at more than 3m/s and exposed to high loads. The pins are treated in a special thermochemical process to achieve an exceptional surface hardness and suitable adhesive strength, which improves the chains’ wear resistance and lifespan. Being used mainly as drive chains, they are not suitable, however, for corrosive environments.

“Megalife maintenance-free roller and conveyor chains have a much longer service life than conventional low- or zero-maintenance roller chains.Benefits for the customer include fewer down-times, longer replacement intervals and significantly lower maintenance costs”, explained Helmut Spell, Key Account Manager at iwis’ headquarters in Munich. “The chains also contribute to sustainability: they are dry, clean and environment-friendly. For the customer that means no need for manual relubrication or lubrication systems as well as lower energy and investment costs and, not least, savings in fossil resources.”

Marketing Manager Irene Christofor-Ziechmann adds that there is plenty of demand for maintenance-free products: “Every year, the number of chain-based conveying applications that are equipped with maintenance-free roller and conveying chains increases by more than 25%. Our proven Megalife product series continues to be a market leader in this sector.”

Similar articles

More from iwis drive systems Ltd

- Website relaunched for increased user friendliness 12th September 2018

- Grip chains for precision feeding, transport and positioning 2nd January 2018

- Series of roller chains designed for high fatigue strength 29th September 2017

- The right accumulation chain for each conveying system 20th July 2017

-(1)ed.jpg)

Write a comment

No comments