The right accumulation chain for each conveying system

A comprehensive range of accumulation chains, especially for logistics and material handling applications are on offer from chain specialist iwis drive systems that have proven exceptionally efficient and durable – and therefore economical – in numerous comparisons. Accumulation chains are used for conveying, accumulating and separating a wide range of different goods.

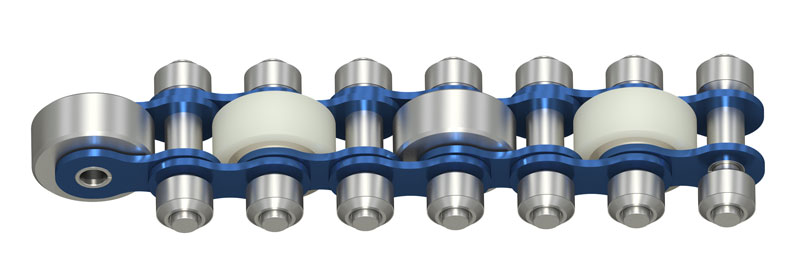

As a rule, these chains run continually, driven through the track rollers on the chains’ outside, which also support the chain in the profile. The conveyed goods rest on the transport or accumulation rollers, which are fitted between the chain links. Accumulation chains from iwis feature special low-friction rollers that ensure an extremely efficient operation of the chain and therefore the entire conveying system. The low-friction rollers also allow easy positioning of the transported material at any point along the transport path and remove the need to start and stop the chain, which could influence product orientation and agitate content.

The accumulation chains are available in different versions, including versions with offset accumulation rollers for optimised load distribution, maintenance-free Megalife accumulation chains with nickel-plated plates and pins for lubricant-free operation, accumulation chains with protection for fingers and small parts for increased machine and personal safety, and side-bow accumulation chains with offset accumulation rollers for conveying systems with extremely small bend radii.

Higher efficiency through low-friction rollers

iwis accumulation chains have idler rollers on both sides that serve two purposes: firstly, they engage with the sprocket teeth to transmit power, and secondly, they support the chain in the profile. The slightly protruding bushes in the inner link prevent contact corrosion between the inner link and outer plate. All 0.5” and 0.75” iwis accumulation chains are fitted with low-friction sintered metal rollers that provide consistent smooth running conditions and are not slowed down by lubricant adhesion. These low friction rollers increase the chain efficiency by 30%, thus decreasing motor capacity due to lower co-efficients of friction or increasing potential conveyor length due to reduced forces.

Optimised load distribution though offset accumulation rollers

Whereas standard accumulation chains have a single wide roller on every second pin, the version with offset accumulation rollers has offset transport rollers on every pin. As a result, each pin has a load-bearing function, so that the load is carried by twice as many rollers. This reduces strain and wear of the chain guide. The offset arrangement of the accumulation rollers ensures maximum load distribution as well as better support and smoother running of the product. It can reduce localised load the chain guides by up to 50%, so plastic guides can now convey up to twice the normal load.

Maintenance-free accumulation chains

A special design with nickel-plated plates and pins and low-friction sintered metal rollers are the main features of the maintenance-fee Megalife accumulation chains. These components negate the need for lubrication and help to further reduce maintenance costs while exhibiting excellent wear resistance under extreme running conditions. These chains are widely used in applications where lubrication is either not possible or could cause contamination, for example food or medical products, electronics, glass, ceramics and many other industries.

Improved safety

Accumulation chains with finger and small parts protection feature cover the space between one transport roller and the next, preventing the ingress of small parts that could jam the rollers and/or chain link. In addition, the cover prevents deliberate or accidental insertion of fingers while the conveyor is operating to increase operator safety. Matched to the chain type and required bending radius, the protectors provide 100% coverage of the space between the transport rollers. The plastic clips are permanently fitted to the inner link. There is no interference with conveyed goods, workpiece carriers or transport rollers. Two different finger and parts protection versions – with and without joint – are available.

Chains for sideflexing conveyor applications

Side-bow accumulation chains with offset accumulation rollers are ideal for sideflexing conveying systems with tight bend radii down to 350mm.The roller arrangement provides multiple contact points, which reduces pressure on product through the bend. This can help to prevent marking or damage and also reduces wear on the system.

The new b.smart accumulation chain

The new b.smart accumulation chain provides proven quality at an attractive price. These low-wear chains are suitable for arduous duty in conveying systems and unite a long service life with high precision.

In addition to accumulation chains, iwis provides a wide product range for all drives and conveying applications. The full programme comprises precision and high-performance roller chains, conveyor chains, maintenance-free and corrosion-resistant chains, accumulation chains, special-purpose conveyor chains, flyer chains, flat-top chains and modular belts for industrial applications, chains and accessories for agricultural machinery, and timing drives for the automotive industry.

Similar articles

More from iwis drive systems Ltd

- Website relaunched for increased user friendliness 12th September 2018

- Grip chains for precision feeding, transport and positioning 2nd January 2018

- Series of roller chains designed for high fatigue strength 29th September 2017

- The right accumulation chain for each conveying system 20th July 2017

Write a comment

No comments