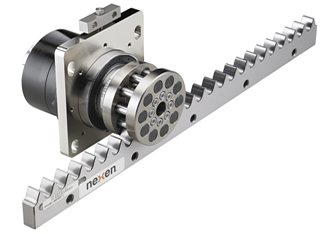

Roller pinion system now in corrosion-resistant stainless steel

A stainless steel version of the patented precision roller pinion system RPS has been introduced by Nexen Group. The RPS engages two teeth simultaneously to achieve accuracy with zero backlash at any length. The system is quiet and efficient.

Stainless steel makes it corrosion resistant, with a long life of up to 36 million metres. Nexen’s RPS provides a low maintenance, durable alternative to rack and pinion, ball screw and belt drive technology. The RPS is used for a wide range of applications including laser and plasma cutting machines and gantry machining centres.

The RPS system uses needle bearings to support the rollers that engage the teeth. This eliminates the sliding friction found in many other motion control systems, leading to an efficiency greater than 99%.

This high efficiency means little is lost to friction, heat, and wear, providing a long life of 60,000,000 pinion revolutions or up to 36 million metres. Further key features include high speeds of up to 11m/s (36ft/sec), superior accuracy of 50µm, zero backlash, and unlimited length, with custom lengths and modular components available.

Nexen produces roller pinion systems, industrial brakes, clutches, torque limiters, overload protection devices and control systems, and the company holds 120 US and international patents.

Similar articles

More from Nexen Group Inc

- Precision rotary motion control in measuring system 22nd May 2019

- Zero-backlash spring engaged brakes for power transmission apps 24th April 2018

- Zero-backlash spring engaged brake family for power transmission 7th March 2018

- Compact ring drive has zero backlash and zero added envelope 18th December 2017

Write a comment

No comments