Air brake & fuel tubing increase performance for trucks & buses

A Synflex DIN/ISO air brake and fuel tubing made from material which withstands elevated pressure, high flexibility and wider temperature has been introduced by Eaton, which is ideal for truck, bus and trailer air brake and fuel applications. Synflex airbrake and fuel tubing products are made from 100% virgin polyamide PHLY thermoplastic material.

The material, along with Eaton’s global manufacturing capability, provides uninterrupted supply and global availability, as well as price stability, for customers.

Product manager Eaton Hydraulics in EMEA, Johannes Kammerlohr said: “Eaton recognises that vehicle manufacturers need fluid conveyance components they can trust to be safe.”

Kammerlohr added: “Over the years, we’ve set the standard for air brake and fuel tubing innovation. Now, we’re using the latest technology to raise the bar. Our new Synflex DIN/ISO air brake and fuel tubing products are the next step in performance, price competitiveness and availability.”

The single wall extrusion of the polyamide thermoplastic material results in a smooth and seamless monowall tubing with a core free from obstruction or foreign materials.

The tubing is also:

- Designed to operate in a temperature range of -40-100°C.

- Designed to operate at a maximum working pressure of 12.5bar (181psi).

- Resistant to effects from gasoline, diesel fuel, methyl alcohol and zinc chloride (compounds usually present in the operating environment of a vehicle).

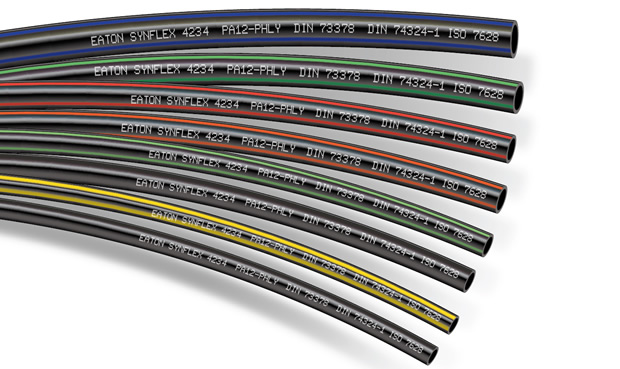

The tubes are manufactured with many different coloured stripes with optimum UV performance, to allow colour-coding of an air or fuel system on a vehicle (an aid in assembly and trouble-shooting). Standard colours include: black, red, yellow, green, blue and natural. Custom colours are available on request.

In addition to the single-wall tubing Eaton offers innovative multilayer Polyamide Tubes using proprietary thermoplastic material for air brake and fuel applications.

Kammerlohr added: “With our wide experience of multilayer design in accordance with SAE and DOT standards, we developed two different multilayer designs to DIN and ISO standards: a 3-layer design which demonstrates outstanding performance in media and temperature resistance; and a 2-layer design, which ideally suits air brake applications.”

Similar articles

More from Eaton Corporation

- IP-based automation system for underground applications 20th November 2020

- Engineering expertise keeps the blades turning 28th September 2020

- Blowout preventer hoses exceed the latest fire test requirements 9th October 2019

- Enhancing configuration software and increases flexibility 15th May 2018

Write a comment

No comments