Wood machining centre uses 28-axis CNC system

A precision wood machining machine based on a 28-axis CNC system from NUM has been launched by Krüsi Maschinenbau. The new MC15 provides very high quality wood machining capabilities and can be equipped with up to 28 axes and a maximum of six machining heads, each of which can be fitted with four machine tools.

Wooden bars with dimensions from 650x300cm, and with a variable length of up to 1200cm and a weight of up to 1.5 tonnes, can be machined easily and quickly from all sides.

Krüsi Maschinenbau AG has a 50 year history of precision high quality wood working machines and are responsible for structures such as Metz' Centre Pompidou in France, the Tamedia building in Zurich or the Nine Bridges golf club in South Korea.

Such structures consist of several hundreds of individual parts where it is rare occurrence that any one piece is like another. The precision systems from Krüsi process all wooden elements, regardless of how complex or delicate the construction.

Apart from high-tech systems for free-form beams, the company’s range of products includes longitudinal circular saws, chalet construction machinery and trimming machines.

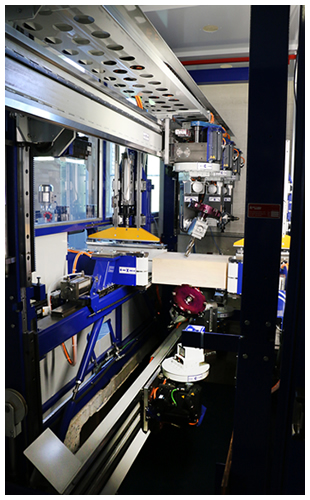

The now completely newly designed MC15 CNC wood machining centre has been developed jointly as the result of close cooperation between Krüsi and NUM. The highly modern CNC wood machining centre enables workpieces of all kinds to be sawn, milled, planed, chamfered, beaded, drilled and grooved from all sides.

The MC15 is suitable for all work pertaining to modern and conventional wood construction engineering, which demands stringent quality and precision.

The MC15 is modular in design, i.e. the number of machining heads and even the dimensions of the loading and unloading station can be adapted as required. The current MC15 is itself built on a gigantic scale in order to machine the aforementioned wooden bars at the maximum dimensions of 30x60x1,200cm.

With a length of 28x3x3x1m (depth below the floor), the modern CNC wood machining centre cannot be overlooked. In order to move the heavy wooden bars weighing up to 1.5 tonnes, the X-axis has four motors, two on each side of the balk.

These are controlled independently. However, in most cases they are used synchronously. The six machining heads are each moved laterally on the Y-axis, each having its own motor. They are mounted on two portals, one above and one below the work piece. The portals are positioned at the height of two Z axes with two motors each.

The six machining heads, each of which is provided with a spindle, can be fitted with up to four tools per head. Alternately, two machining heads can continuously machine the wooden bar, one from below and the other from above.

The 28 axes are controlled with the help of a NUM Flexium+ CNC controller. Apart from the integrated safety controller, the CNC wood machining centre has NUMDrive X drives to control the axes and SHX single cable motors to drive the axes, as well as an FS192LS touch-sensitive screen to control the machine.

Allthese components come from NUM, since this is the only way that proper and precise working of the machine can be ensured for a machining operation from beginning to end.

Similar articles

More from NUM (UK) Ltd

- Latest tool grinding software increases precision productivity 29th March 2018

- Graphical software brings shop floor programming simplicity 28th September 2017

- US machine control manufacturer uses CNC system for precision grinding 12th October 2016

- Wood machining centre uses 28-axis CNC system 12th October 2016

ed.jpg)

Write a comment

No comments