Sheffield subcontractor takes the big capacity route to machining

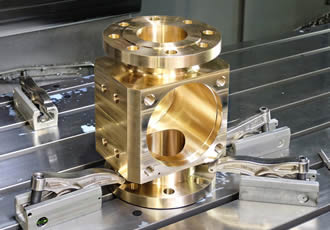

Sheffield contract machining firm Ian Cocker Engineering, for the later part of its career, has relied on almost only Hurco vertical machining centres to produce prismatic components, mainly for the oil and gas sector and frequently from difficult materials such as stainless steel and Inconel.

However in wanting to extend its capacity in terms of both size and versatility, the company has installed its first 5-axis model, a Hurco VMX84SWi. The machine is the largest in the manufacturer’s VMX range and the first to be installed in the UK.

Proprietor Ian Cocker said: “The large working envelope means that we can machine parts that we previously had to turn away.

“We produce them cost effectively, as the machine has an integral B-axis spindle head and we have added a fifth CNC axis by purchasing a Kitagawa rotary table.

“It is a very versatile 5-axis solution, as we can use the rotary table either upright or on its back to tackle five sides of a component in one hit, or for full simultaneous 5-axis cycles.

“Then if we take it off the table, long components measuring over 2.1m can undergo up to 4-axis CNC milling and drilling.”

In 2014, volume production for the oil and gas industry accounted for 80% of the subcontractor’s turnover. That figure halved due to the slowdown in the sector. Luckily, much of the shortfall was replaced by development contracts in the same field, while additional work was won from the AMRC (advanced manufacturing and research centre) at Sheffield University and also from Sheffield Forgemasters.

A batch of components for the latter customer was one of the first jobs to be put onto the VMX84SWi, which was installed in September 2015. The project involved re-engineering seven rack segments, one-metre long, for the axis drives on a Chinese-built floor-type milling machine in use at Sheffield Forgemasters. Each segment required 40 teeth to be machined at an 11° angle to an accuracy of 15µm. Cocker continued: “Having the B-axis on the big machining centre was ideal for completing this job, as it avoided having to tilt the components to mill the teeth and also chamfer the end of each tooth.

“Another component recently completed on the machine involved 3+2-axis milling of a test equipment component requiring angled ends and slots.

“Previously, it took a couple of hours to set up the job on a 3-axis machine, because the part had to be tilted and test cuts made and measured before production could start.

“Setting the same job up on the new Hurco 5-axis machining centre with the help of Renishaw part probing takes about ten minutes, saving an enormous amount of time.”

He pointed out that in engineering, a machine tool is never quite big enough to tackle all the parts that come along. Subcontractors have a tendency to take on work that is right on the physical limits of their capacity, or even a little too big, and then improvise to get around the problem by re-fixturing the component, taking off end guarding or other means.

This is all in the past at Ian Cocker Engineering, as the 2,135x865x760mm travels of the VMX84SWi are more than sufficient to complete all jobs coming from the subcontractor’s current customer base. The machine has differentiated the firm from its competitors and allowed it to take on additional, niche work that others cannot tackle.

This advantage is about to be taken a step further. Cocker has recently upgraded the company’s OneCNC CAM system for off-line G-code programming to a seat of Open Mind hyperMILL 5-axis CAM software. It provides the ability to produce fully-interpolative 5-axis cutting cycles for running on the new Hurco machine, allowing the subcontractor to accept work requiring complex features and profiling.

Despite this investment, until now 19 out of every 20 cutting cycles for the four Hurco machining centres on the shop floor, including 3+1 routines as well as 3+2 for the new machine, are prepared using WinMAX 9 conversational programming software running in the machines’ proprietary control systems. Only occasionally has Hurco’s NC Merge feature been employed to construct cycles from conversationally programmed content combined with G-code blocks generated by the OneCNC software.

Cocker advised: “WinMAX programming software is incredibly easy to use. It was a big factor in our purchase in 2008 of the first Hurco machining centre, a VMX 50, which has a 1,500x660mm table. The machine can be up and running in five or ten minutes to produce a new job, which is especially useful for one-offs.

“At the time, we benchmarked the machine against a similar capacity model with a conventional control from another supplier. After speaking with users of both types, we concluded that by the time we were cutting on the Hurco, we would still have been programming the other machine.”

Despite the VMX 50 being of relatively large capacity, Cocker said that the machine still holds very tight tolerances and that features are routinely machined to within 10µm, even after eight years of service. The other two machining centres in use at the Sheffield site are a smaller VM3 with a fourth CNC axis and a VM10 3-axis model, installed in 2012 and 2014 respectively, which alleviated the queue of work that was invariably waiting for the VMX 50.

Similar articles

More from Hurco Europe Ltd

- Four big launches at Hurco's 50th year at MACH 5th March 2018

- EDM company expands milling capacity with 5-axis machines 12th February 2018

- Machining solutions for simple and complex solutions 10th January 2018

- Aerospace subcontractor expands machining centre 20th December 2017

ed.jpg)

Write a comment

No comments