Next-gen turn-mill centre offers improved performance

Launched at the AMB 2016 show in Stuttgart during September, the second generation of the G200 turn-mill centre from German manufacturer INDEX is now available in the UK and Ireland through Geo Kingsbury.

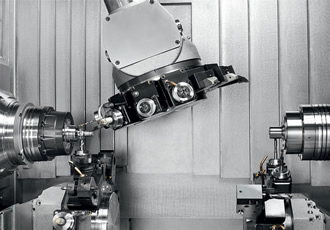

The twin-spindle machine, which has a compact footprint similar to that of its predecessor, has been extensively improved. Distance between centres is up from 400mm to 660mm, a second tool carrier has been added below the spindle centre line, reducing cycle times by typically 30%, and the speed of the B-axis milling spindle has been increased from 2,000rpm to 7,200rpm. The result is a flexible, three-turret lathe for productive, complete machining of bar stock up to 65mm diameter and chuck parts up to 165mm diameter.

A significant change compared to the first-generation G200 is that the heavily ribbed, low vibration, cast machine bed is arranged vertically, a design that INDEX pursues in almost all its new products. Although such machines tend to be slightly taller, they have a smaller footprint and provide extra space in the working area, permitting all three tool carriers to work simultaneously at either the main or counter spindle without interference. The fluid cooled spindles are identical, rated at 32kW / 170Nm / 6,000rpm.

The two lower turrets are arranged in mirror image, each having a ±45mm Y-axis. They contain 14 tool stations, all of which can be equipped with live tools driven at up to 7,200rpm by a 16kW motor. The turrets may be parked outside the machining area, giving the top tool carrier unrestricted access to the workpiece, for example to allow collision-free machining without stopping along the entire length of a shaft.

The upper tool carrier deploys a 14-station turret and an integrated, HSK-A40 milling spindle. It has ±65mm of Y-axis movement and a 360 degree swivelling B-axis. In addition to its elevated speed range, the 845mm horizontal travel covers the complete turning length of 660mm, without having to rotate the B-axis, as is often the case on other lathes.

With Industry 4.0 in mind, the INDEX Xpanel i4.0 focuses on productivity and ease of use. Building on the Siemens S840D sl, it reduces the complexity of control operation. For example, many elements of the control panel have been integrated into the 18.5” widescreen display, which uses the latest capacitive touch technology. It is possible at the push of a button to toggle between the control screen and a second screen displaying, for example, INDEX Virtual Machine for cycle simulation and crash detection.

Furthermore, an optional PC installed in the control cabinet allows the NX CAM system, supported by an INDEX post-processor, to run directly on the machine. From the control panel, the machine operator can also obtain information from a network, such as component drawings and tool data to assist set-up.

Downloads

Similar articles

More from Geo Kingsbury Machine Tools Limited

- Cell for machining airbus engine pylons 17th July 2018

- Portal mill for prototype tool and mould making 7th February 2018

- Manufacturing solutions reduce cost of production 6th February 2018

- Entering the additive manufacturing sector 2nd February 2018

ed.jpg)

Write a comment

No comments