Mouldmaker chooses bridge-type machining centre

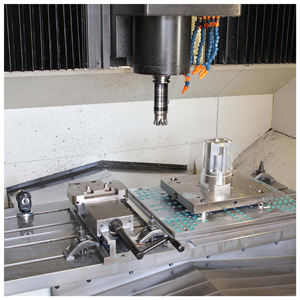

As precision mould manufacturer and injection moulding specialist BM Injection was looking to replace an ageing, 3-axis, vertical-spindle machining centre of C-frame design back in the autumn of 2016, the company had three main requirements for the new machine. It needed to be of bridge construction for improved rigidity and have a nominal one-metre X-axis to provide extra capacity. It also had to be able to compensate for fluctuations in temperature on the shop floor.

Technical director Mark Combes already had a good idea which machining centre they would choose, having seen a stripped-down Okuma Genos M560-V several months earlier at MACH 2016 on the stand of the Japanese manufacturer’s UK agent, NCMT.

The machine model was suitable for BM Injection’s requirements in terms of size, construction and price. An added benefit was the small footprint of less than eight square metres for the 1,050x560x460mm work envelope, space being limited and expensive at the Whitchurch factory in Hampshire.

What clinched the mouldmaker’s decision to opt for this make of machining centre was Okuma’s Thermo Friendly Concept, whereby the cutting performance of Genos M560-V machines (and many others in the manufacturer’s range) has been mapped across a wide temperature range in the R&D centre at the Japanese factory.

Temperature sensors incorporated into both the thermo-symmetrical structure and oil-cooled spindle of the machine allow the predictable, uniform thermal expansions and contractions to be maintained within 10µ by compensation software built into the control, despite ambient temperature variation of up to 8°C. This is achieved with the help of Okuma’s own 0.1µ resolution linear scales fitted in the orthogonal axes.

Combes said: “We don’t have air-conditioning on the shop floor, but nevertheless need to hold tolerances of 8µm on some mould features.

“The Okuma allows us to do that and also produces an excellent surface finish, minimising the need for hand polishing. The machine it replaced could not meet the same standards of accuracy, even when new.”

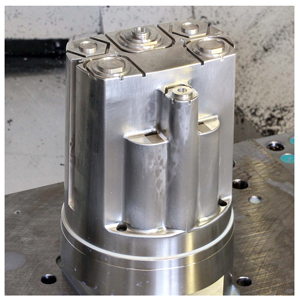

He added that the 22kW/200Nm/15,000rpm BIG-Plus spindle with face and taper contact has the power to deal with the heavier side of toolmaking, in particular accurate bolster work, precision boring and heavy roughing of tool steels. The magazine can hold 32 tools and cutting feed rate is up to 32m/min, allowing fine finish machining as well as tough metalcutting.

Toolroom supervisor Ian Mancey likes another feature of the machine, namely the Y-axis movement of the table that allows jobs to be loaded and unloaded conveniently at the front of the working area, avoiding having to reach in very far. He also cites the generous 1,300mm length of the table, 250mm longer than the X-axis travel, which allows clamps to be mounted at either end without compromising spindle traverse.

The Genos M560-V has the added benefit of the manufacturer's proprietary OSP-P300M-R control, which uses an industrially hardened PC to run both the Okuma operating system and Windows. A feature of the CNC system is comprehensive collision prediction and avoidance. The entire machining area right out to the spindle head, slideways and guarding is monitored in real time during an automatic machining cycle or, unusually, in manual mode as well, preventing the axes from being wound by hand into a collision situation.

The Genos M560-V has the added benefit of the manufacturer's proprietary OSP-P300M-R control, which uses an industrially hardened PC to run both the Okuma operating system and Windows. A feature of the CNC system is comprehensive collision prediction and avoidance. The entire machining area right out to the spindle head, slideways and guarding is monitored in real time during an automatic machining cycle or, unusually, in manual mode as well, preventing the axes from being wound by hand into a collision situation.

Combes added: “NCMT has given us a high level of support. Two of its engineers installed and commissioned the machine efficiently, clamping it to the floor and calibrating it carefully so that we are able to exploit its full accuracy potential.

“The supplier also provided comprehensive training, including two days at its Coventry centre prior to installation followed by five days here in Whitchurch.”

BM Injection, which was established in 1984 by Combes’ father, Timothy, manufactures mould tools weighing up to three tonnes and produces injection moulded parts up to 800g. What places the company in a group of only around a dozen in the UK is the high, ongoing level of investment in both sides of the business. £400,000 has been spent in the toolroom alone in the last two years and a similar sum on the injection moulding side.

The wide customer base includes firms in the aerospace supply chain, the company being a Boeing approved supplier. It is also active in the automotive, white goods, electronics, transport and leisure sectors, delivering moulds as well as thermoplastic and thermoset moulded parts and assemblies.

Similar articles

More from NCMT

- 5-axis machining centres showcased at MACH 13th February 2018

- Prismatic machining, turning and grinding centres on show at MACH 13th February 2018

- Valve manufacturer adopts interpolation turning 12th January 2018

- Adhesive workholding system demonstrated at EMO 1st August 2017

ed.jpg)

Write a comment

No comments