Integrating single servo axis into high-speed rotobroacher

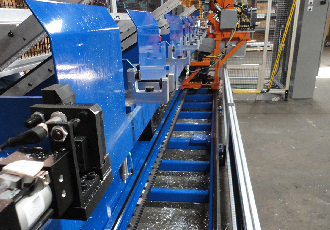

Michigan-based company Lumco Manufacturing, designs, builds and integrates automation and special machine equipment for the automotive, agricultural, gas and oil, energy and aerospace industries. Recently, Lumco custom-built a single-spindle multi-station aluminium drilling and rotobroaching machine to be used to manufacture components of a construction industry aluminium brake.

The machine is programmed to handle 21 part configurations with part lengths ranging from 2.24.4m (7ft.3” to 14ft.6”), with a manual load/auto unload.

Lumco engineers were looking for a way to incorporate a single servo axis that could handle 4.9m (16ft) of travel at speeds of up to 0.6m/s (2ft/s), and operate in an environment contaminated by aluminium chips.

Their options came down to a traditional ball screw arrangement, belt drive actuation, or standard rack and pinion. Ball screw was ruled out due to the length of travel needed, belt drive was ruled out due to lack of accuracy. Standard rack and pinion could handle the distance and speed, but the associated backlash and wear eventually ruled it out as well.

After some research, Lumco contacted Nexen Group for help. Nexen suggested its RPS roller pinion system, which offered higher speeds, higher accuracy, lower backlash and predictable life. Working together, they factored in the speed, weight and forces of the application to select the correct components to meet the customer’s cycle time requirements.

Once projected life and system accuracy were calculated, Lumco determined the RPS roller pinion was their most viable option.

“We were struggling to use our traditional ball screw solution on this long of a machine. The Nexen RPS offered the accuracy, speed and low backlash for the long transfer this system required”, said Mike Morris, President of Lumco.

Nexen worked on-site at Lumco to ensure that they had the correct data and design parameters to properly size the system. The biggest challenge was incorporating the RPS rack into the design for ballscrew mounting. Once aligned correctly, the rest of the assembly went quickly and the system ran smoothly from day one.

Tim Dillon, Vice President of Sales and Marketing at Nexen said: “We recommended RPS roller pinion because it provided long predictable life, high precision and the ability to run in contamination conditions. This particular system was for an aluminium-boring drilling machine, but it could be used in virtually any longer transfer drilling or boring application for any kind of material.”

“Knowing RPS roller technology is available gives us more options to package servo axes, especially on longer travel systems. We aren’t dependent on the typical ball screw approach, which limited both length and speed of the machine design. RPS allows us all the accuracy and speed of a ball screw at any length of travel we need”, said Mike Morris, President, Lumco. “Ease of integrating the RPS into our machine design and assembly was an unexpected advantage over a ball screw. Most importantly, our customer is very happy with the machine performance.”

Similar articles

More from Nexen Group Inc

- Precision rotary motion control in measuring system 22nd May 2019

- Zero-backlash spring engaged brakes for power transmission apps 24th April 2018

- Zero-backlash spring engaged brake family for power transmission 7th March 2018

- Compact ring drive has zero backlash and zero added envelope 18th December 2017

ed.jpg)

Write a comment

No comments